Water-based electrochemical aluminum packaging composite film color layer ink

A technology of anodized aluminum and composite film, which is applied in the field of coatings, can solve problems such as pollution to the environment and health, cumbersome production and processing technology, and complex materials, and achieve the effects of convenient storage and use, good stability, and good light fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0041] The composition of the aqueous fluorescent liquid is by weight percentage:

[0042] Fluorescent substance: 4.0%;

[0043] Deionized water: 45%;

[0044] Ethanol: 51%.

[0045] The preparation method of the water-based fluorescent liquid is as follows: first add deionized water and alcohol determined according to the composition of the water-based fluorescent liquid in the reaction container, start the disperser at 500-600r / min, then add fluorescent substances, disperse for 30-50 minutes, filter and pack stand-by.

preparation example 2

[0047] The composition of the aqueous fluorescent liquid is by weight percentage:

[0048] Fluorescent substance: 3.0%;

[0049] Deionized water: 43%;

[0050] Ethanol: 54%.

[0051] The preparation method of the water-based fluorescent liquid is as follows: first add deionized water and alcohol determined according to the composition of the water-based fluorescent liquid in the reaction container, start the disperser at 500-600r / min, then add fluorescent substances, disperse for 30-50 minutes, filter and pack stand-by.

preparation example 3

[0053] The composition of the aqueous fluorescent liquid is by weight percentage:

[0054] Fluorescent substance: 2.0%;

[0055] Deionized water: 47%;

[0056] Ethanol: 51%.

[0057] The preparation method of the water-based fluorescent liquid is as follows: first add deionized water and alcohol determined according to the composition of the water-based fluorescent liquid in the reaction container, start the disperser at 500-600r / min, then add fluorescent substances, disperse for 30-50 minutes, filter and pack stand-by.

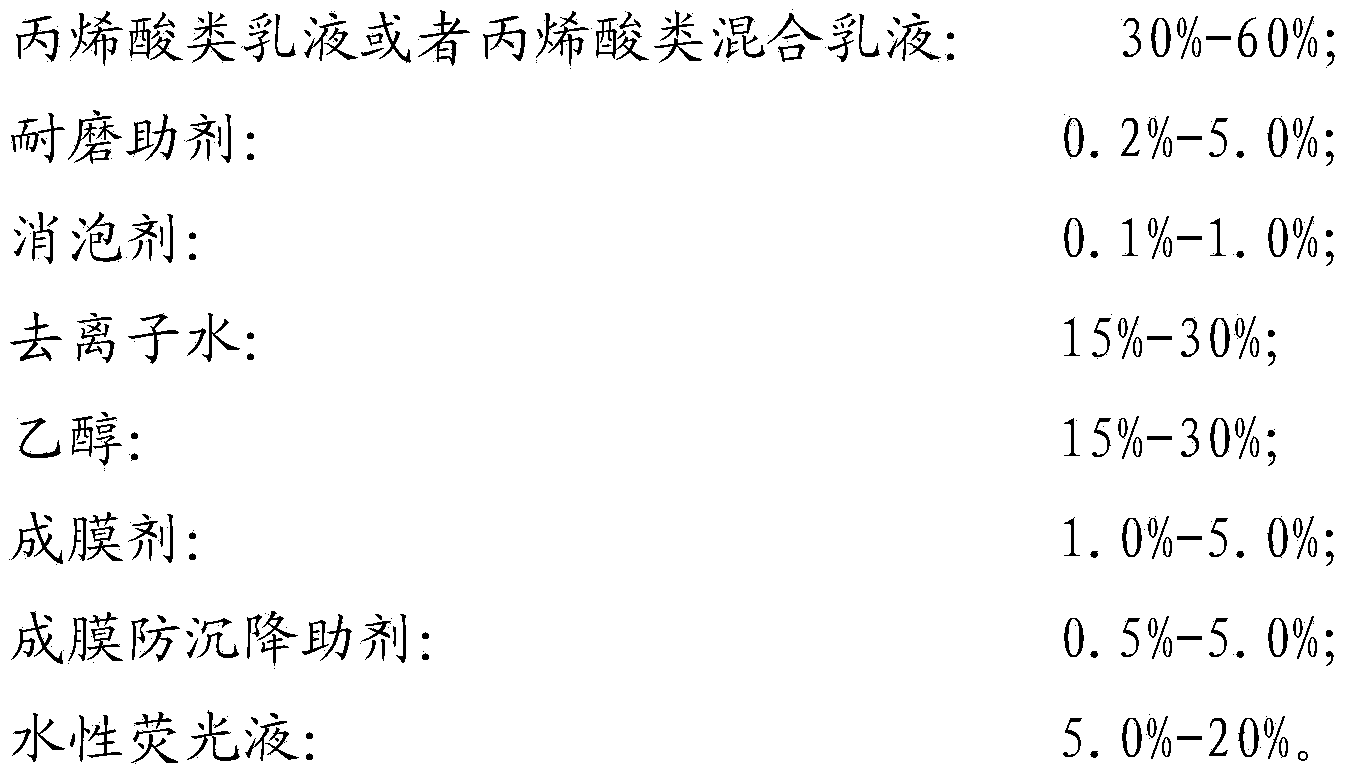

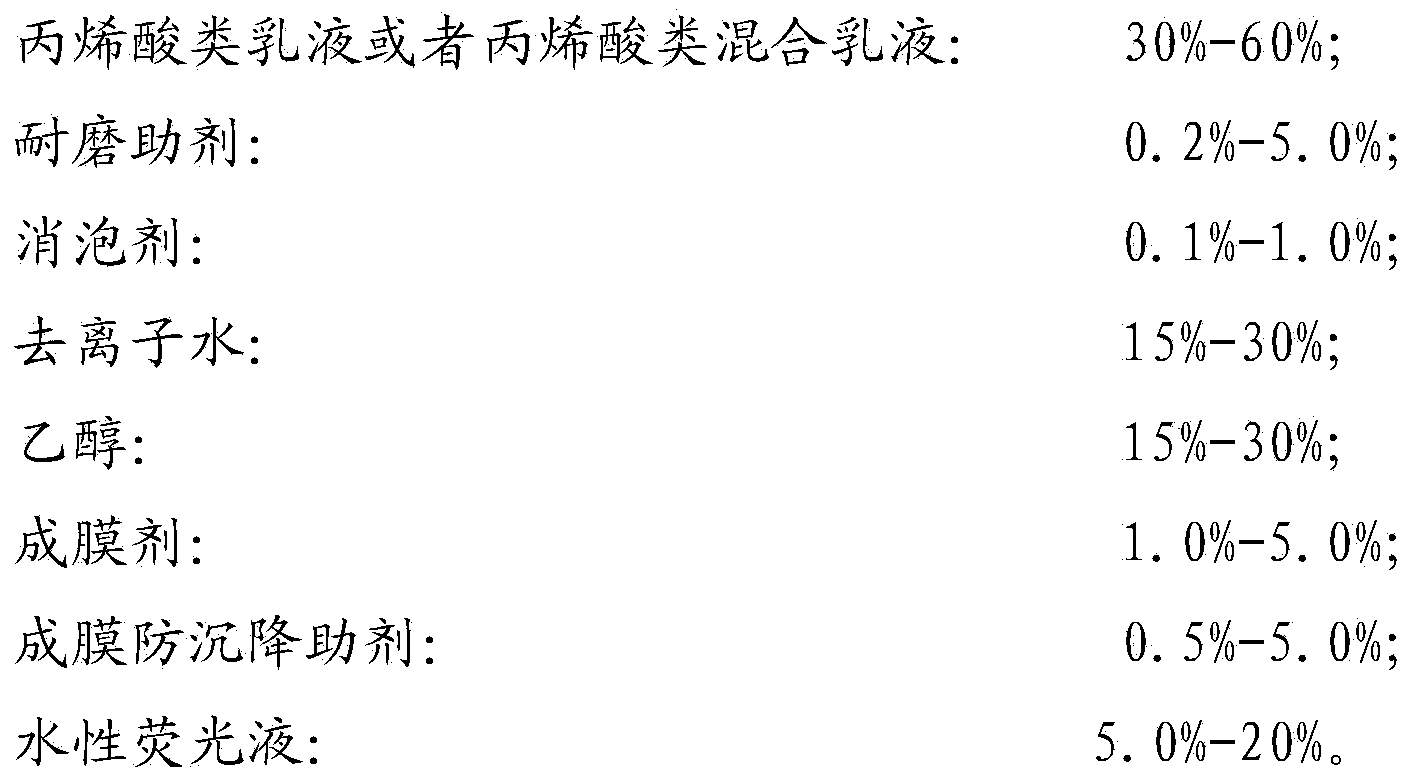

[0058]The preparation embodiment of water-based anodized aluminum packaging composite film color layer ink is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com