Preparation method and application of biopolymer binder

A biopolymer and binder technology, applied in non-polymer binder additives, grafted polymer binders, adhesives, etc., can solve problems such as high cost, environmental pollution, non-renewable, etc., to improve the surface Strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

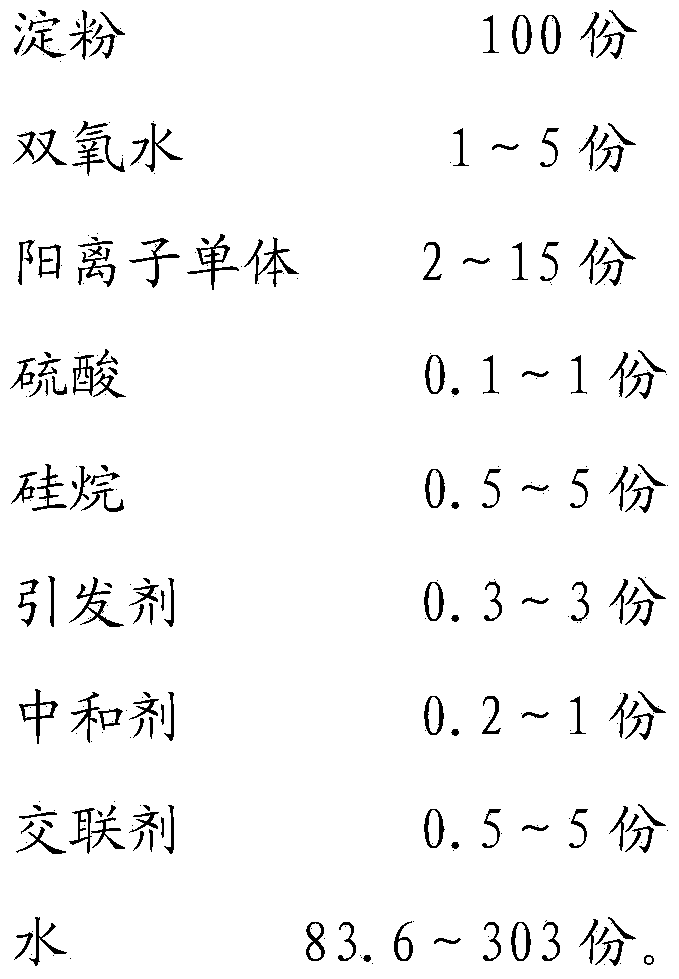

Method used

Image

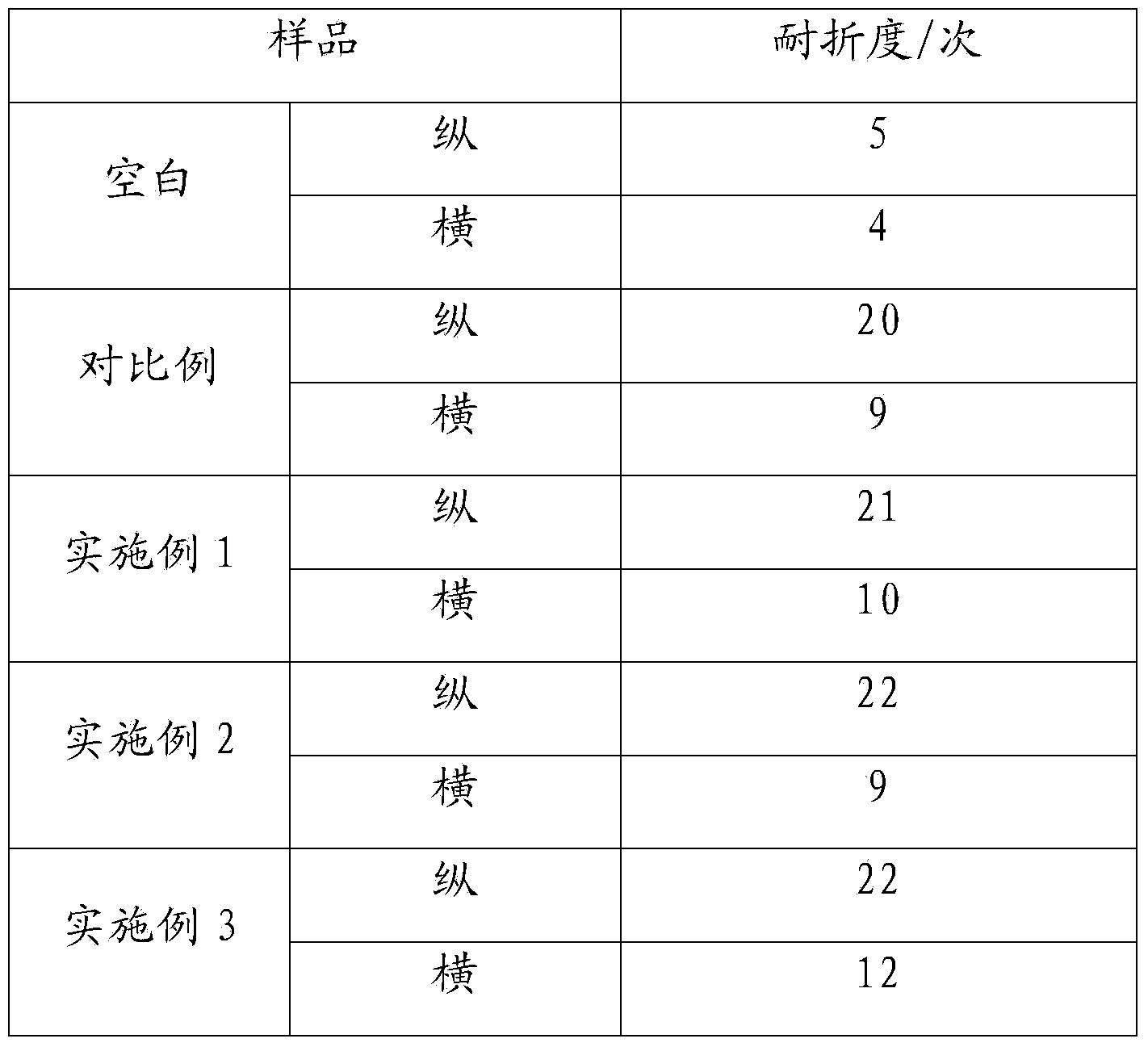

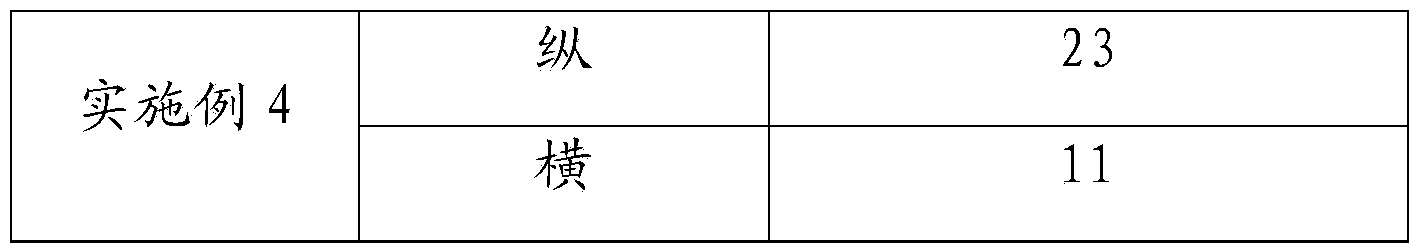

Examples

Embodiment 1

[0027] Synthesis of biopolymer binders:

[0028] a) 0.3g potassium persulfate is dissolved in 5g deionized water to be dissolved into initiator aqueous solution, for subsequent use;

[0029] b) Add 100g of cornstarch and 78.65g of deionized water into a 1000ml four-neck flask, dissolve, and heat up to 60°C;

[0030] c) At 60°C, add step a) 1g of hydrogen peroxide with a weight concentration of 25% and 0.1g of sulfuric acid with a weight concentration of 15% into a four-necked flask, and keep warm at 60°C for 1 hour.

[0031] d) Heating up to 70°C again, adding 1.06g of initiator aqueous solution into a four-necked flask, and incubating at 70°C for 10 minutes; simultaneously adding 2g of dimethyl diallyl ammonium chloride, 0.5g of vinyltriisopropoxy Silane and the remaining amount of initiator aqueous solution were added dropwise for 1 hour.

[0032] e) Insulate at 70°C for 1 hour, cool down to 40°C, add 0.5g glyoxal, stir for 0.5 hours, then cool down to 25°C, add 0.4g aqueo...

Embodiment 2

[0034] Synthesis of biopolymer binders:

[0035] a) Dissolve 3g of sodium persulfate in 5g of deionized water to form an aqueous initiator solution, and set aside.

[0036] b) Add 100g of tapioca starch and 297.64g of deionized water into a 1000ml four-neck flask, dissolve, and heat up to 80°C;

[0037] c) At 80°C, add 5g of hydrogen peroxide with a weight concentration of 30% and 1g of sulfuric acid with a weight concentration of 20% in step a) into a four-necked flask, and keep warm at 80°C for 1 hour.

[0038] d) Heating up to 90°C again, quickly adding 2.4g of initiator aqueous solution into a four-necked flask, and keeping it warm at 90°C for 5 minutes; at the same time, 15g of methacrylic acid acyloxyethyltrimethylammonium chloride and 5g of γ-methylpropene were added dropwise Acyloxypropyltrimethoxysilane and the remaining amount of initiator aqueous solution were added dropwise for 3 hours.

[0039] e) Insulate at 90°C for 1 hour, cool down to 30°C, add 5g of glutara...

Embodiment 3

[0041] Synthesis of biopolymer binders:

[0042] a) 2g of ammonium persulfate is dissolved in 5g of deionized water to form an aqueous initiator solution, which is set aside.

[0043] b) Add 100g of potato starch and 107.9g of deionized water into a 1000ml four-neck flask, dissolve, and heat up to 70°C;

[0044] c) At 70°C, add step a) 3g of hydrogen peroxide with a weight concentration of 27.5% and 0.5g of sulfuric acid with a weight concentration of 18% into a four-necked flask, and keep warm at 70°C for 1 hour.

[0045] d) Heat up to 80°C again, quickly add 1.5g of initiator aqueous solution into a four-necked flask, and keep it warm at 80°C for 8 minutes; at the same time, dropwise add 10g of methacrylic acid acyloxyethyl trimethyl ammonium chloride, 3g of vinyl triethyl Oxysilane and the remaining amount of initiator aqueous solution were added dropwise for 2 hours.

[0046] e) keep warm at 80°C for 1 hour, cool down to 35°C, add 1g of glutaraldehyde and 2g of sodium he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com