Electrode pitch and preparation method thereof

A pitch and electrode technology, applied in the field of electrode pitch and its preparation, can solve the problems of high softening point of pitch and cannot meet the requirements, etc., and achieve the effects of high coking value, low QI content, and reduced interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The method for preparing electrode pitch of the present invention comprises:

[0029] (1) Extract the coal direct liquefaction residue with an organic solvent to obtain extracted pitch, wherein the organic solvent is a mixture of one or more of the following compounds: alicyclic hydrocarbons, aromatic hydrocarbons, chlorinated aromatic compounds, chlorine Aliphatic hydrocarbons, alcohols, aldehydes, ketones, sulfones, sulfoxides, ethers, carbon disulfide, pyridine, amides, petroleum distillates and liquefied oils produced during the direct liquefaction of coal; and

[0030] (2) Treat the extracted pitch at 350-420°C in an inert atmosphere to obtain electrode pitch.

[0031] Each step is detailed below.

[0032] step 1)

[0033] In the step (1) of the method of the present invention, the coal direct liquefaction residue is extracted with an organic solvent, and the obtained extract is removed from the solvent to obtain the extracted pitch. The organic solvent can be ...

Embodiment 1

[0061] (1) First, the above-mentioned coal direct liquefaction residue and the IBP-110°C liquefied oil produced during the coal direct liquefaction process were subjected to primary extraction at a volume ratio of 1:3 for 50 minutes; the mixture obtained by the primary extraction was separated into solid and liquid , the obtained solid part and the 220-260 °C liquefied oil produced during the direct coal liquefaction process were subjected to secondary extraction for 60 minutes at a volume of 1:3, and the soluble part obtained from the two-stage extraction was recovered to obtain the extracted pitch.

[0062] (2) Put the extracted pitch and coal tar in a ratio of 1:0.8 into a closed autoclave, raise the temperature to 380°C at a rate of 2°C / min under a nitrogen atmosphere, and keep the temperature for 8 hours to obtain electrode pitch.

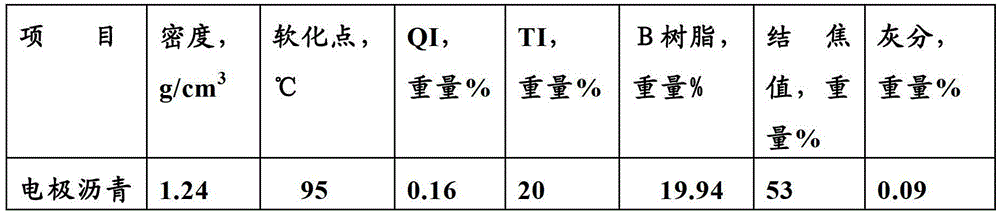

[0063] The indexes of the extraction pitch, coal tar, and electrode pitch in Example 1 are shown in Table 1 below.

[0064] Table 1 Character...

Embodiment 2

[0068] (1) Obtain the extracted pitch through the step (1) in Example 1.

[0069] (2) Put the extracted pitch and coal tar in a ratio of 1:0.8 into a closed autoclave, and raise the temperature to 400°C at a rate of 3°C / min under a nitrogen atmosphere and keep the temperature constant for 6 hours to obtain electrode pitch.

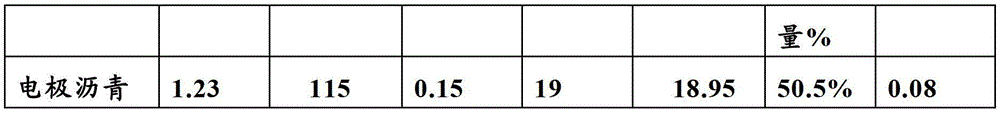

[0070] The indicators of the obtained electrode pitch are shown in Table 2 below.

[0071] Table 2 Properties of electrode pitch

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com