Oxygen-rich side-blowing molten pool copper and sulfonium melting production technology and three-side blown melting furnace

A smelting furnace and copper matte technology, which is applied in the production process of smelting copper concentrate into copper matte with high-concentration oxygen-enriched air, can solve the problems of large output of slag, large amount of flux added, waste of copper resources, etc., and achieve The effects of reducing copper content in slag, reducing slag output and improving smelting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

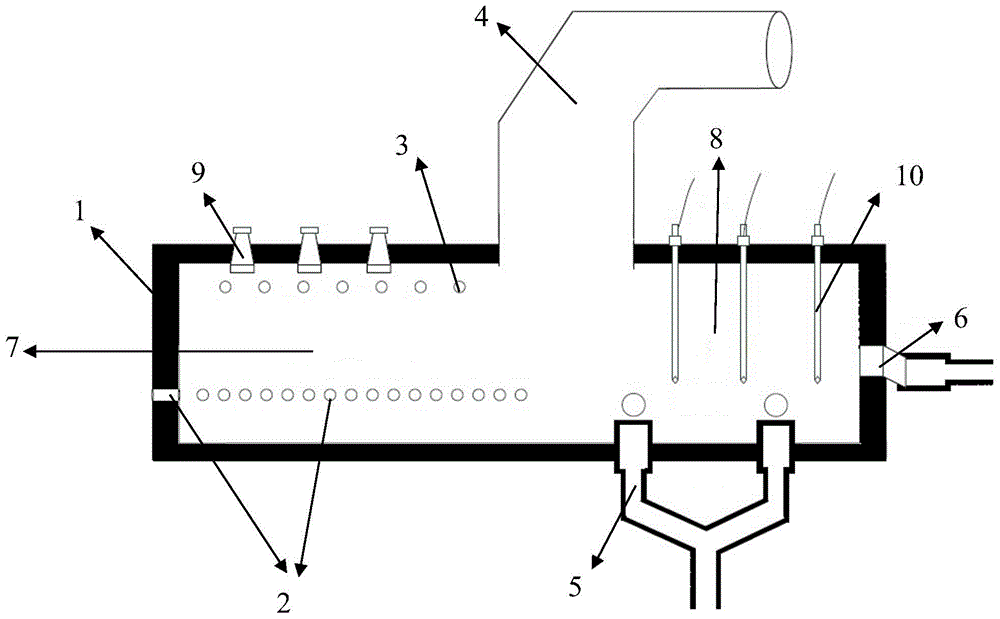

[0028] Such as figure 1 As shown, a fixed three-side blowing smelting furnace includes a furnace body 1, an oxygen-enriched air inlet 2, a secondary air outlet 3, a flue 4, a copper matte outlet 5, and a slag discharge outlet 6. The furnace body It is divided into a smelting zone 7 and a settling zone 8. There is a feed inlet 9 on the furnace body at the top of the smelting zone 7. The furnace body on both sides and one end of the smelting zone 7 is equipped with an oxygen-enriched air inlet 2 and an oxygen-enriched air inlet. 2 Located 0.5m below the top surface of the slag layer or between the slag layer and the copper matte layer, high-concentration oxygen-enriched air is blown into the furnace body from the oxygen-enriched air inlets 2 on both sides and at the end of the smelting zone 7 to participate in the smelting reaction, smelting The upper part of the melt on both sides of zone 7 is provided with secondary tuyeres 3, and ordinary air is blown into the furnace from se...

Embodiment 2

[0031] The melting furnace is the same as in Example 1.

[0032] Firstly, raw materials such as copper concentrate, quartzite flux, slag concentrate and copper-containing materials are adjusted to S / Cu1.5 to produce slag Fe / SiO 2 The ratio of 1.8 is required to be metered and sent to the mixing bin. The mixed material is fed into the melting furnace from the feed port 9 on the top of the furnace body, and air with an oxygen-enriched concentration of 75% is blown in, and the blast pressure is 0.15Mpa. The top negative pressure is -150~-200Pa, the flue gas temperature is about 1300°C, the slag temperature is 1280±50°C, the temperature of the copper matte produced is 1180±20°C, the mixed furnace charge is oxidized by oxygen-enriched air to form slag, and the copper matte and slag produced Sedimentation and separation are carried out in a relatively static settling area, and the copper matte with a large specific gravity settles to the bottom of the furnace and flows out from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com