Lightweight fireproof energy-saving prefabricated exterior-wall hanging plate and construction method thereof

An energy-saving and fire-resistant technology, applied in building components, buildings, building structures, etc., can solve the problems of easy failure of sealing materials, degradation of mechanical properties, fire spread, etc., to increase the effect of thermal insulation and energy saving, reduce production costs, and ensure thermal insulation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The lightweight, fire-resistant, energy-saving prefabricated exterior wall hanging panel and its construction method of the present invention will be further described in detail below.

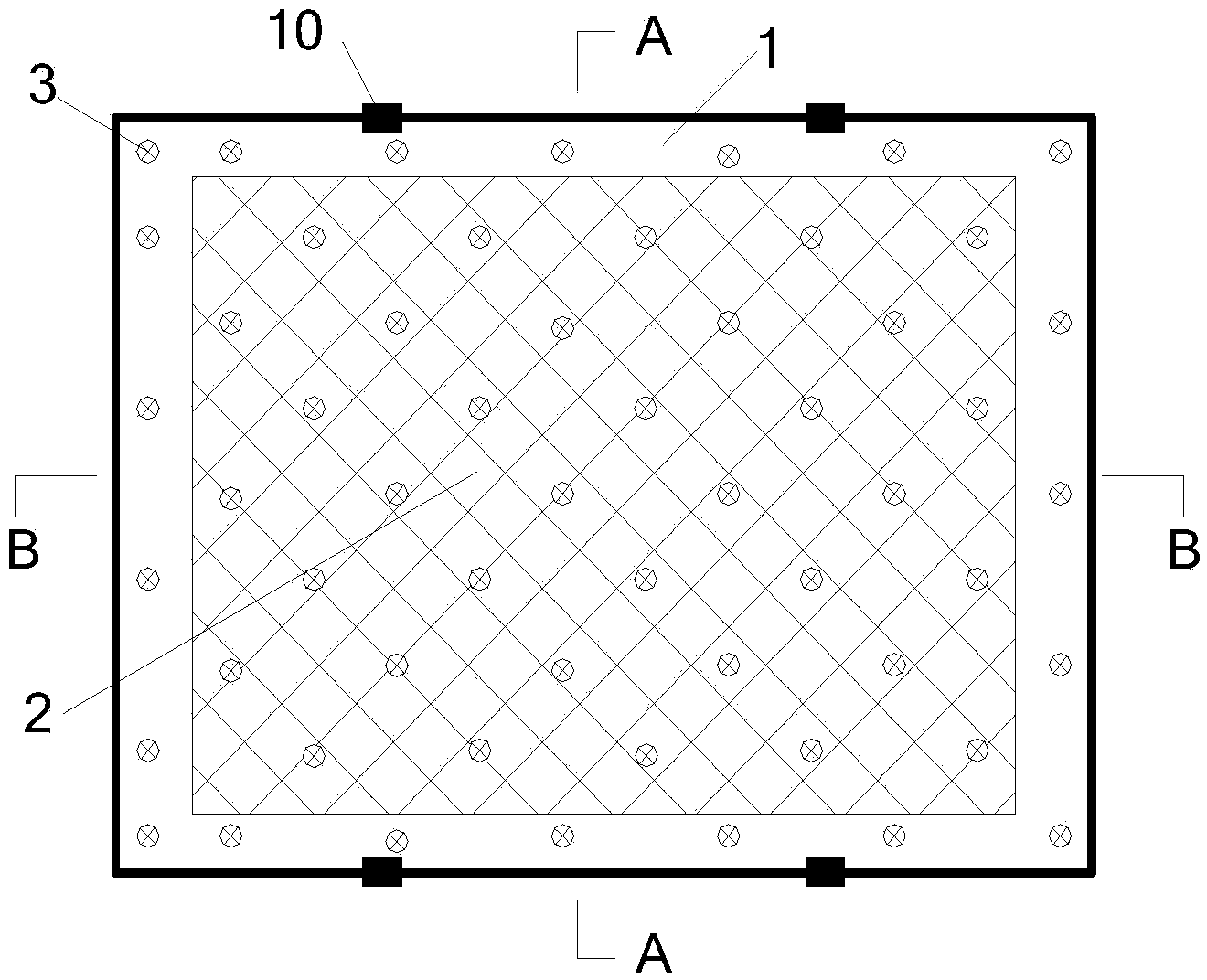

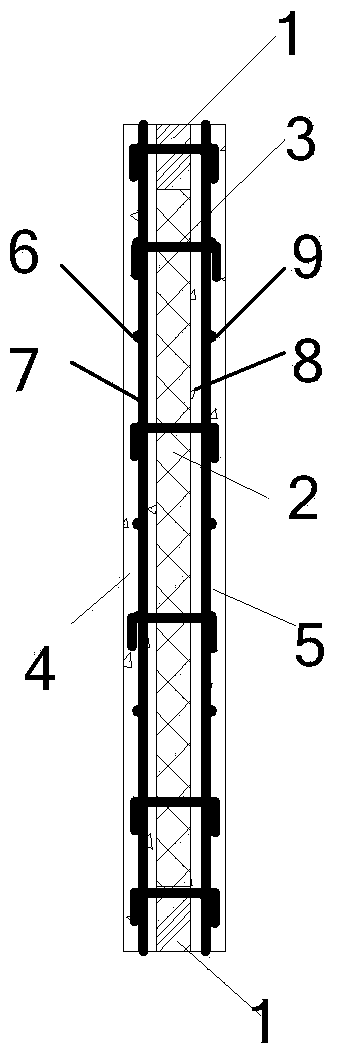

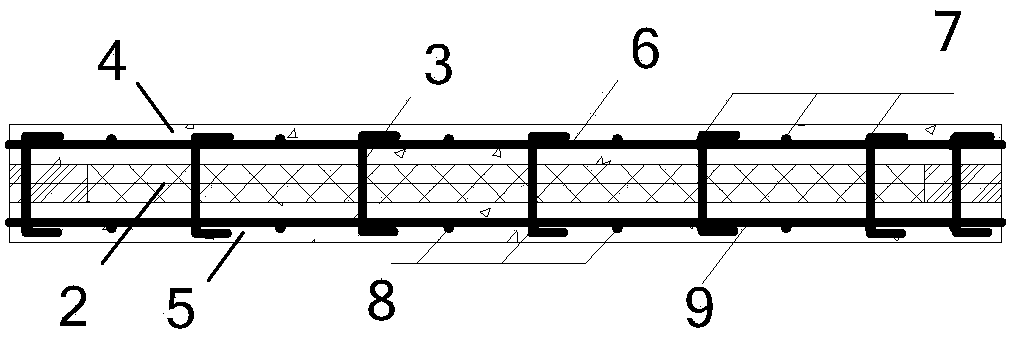

[0038] see Figure 1 to Figure 5 , this embodiment discloses a lightweight, fire-resistant, energy-saving prefabricated exterior wall hanging panel, comprising at least one wall panel, the wall panel includes an inner reinforced concrete panel 4, an outer reinforced concrete panel 5, an insulating material layer , and heat-resistant connecting ribs 3; the thermal insulation material layer is interposed between the inner and outer reinforced concrete panels 4, 5; the thermal insulation material layer includes an organic thermal insulation part 2 and is wound around the organic thermal insulation part 2 around the inorganic thermal insulation part 1, the organic thermal insulation part 2 occupies most of the thermal insulation material layer. Since the organic insulation part 2 is laid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com