Cooling and power combined supply method and device of adsorptive heat pump

An adsorption heat pump and compression heat pump technology, which is applied in the direction of refrigerators, steam engine devices, adsorption machines, etc., can solve the problems of low practical value, high initial temperature, and low efficiency of steam power machinery, so as to reduce cooling water consumption, The effect of reducing exhaust temperature and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

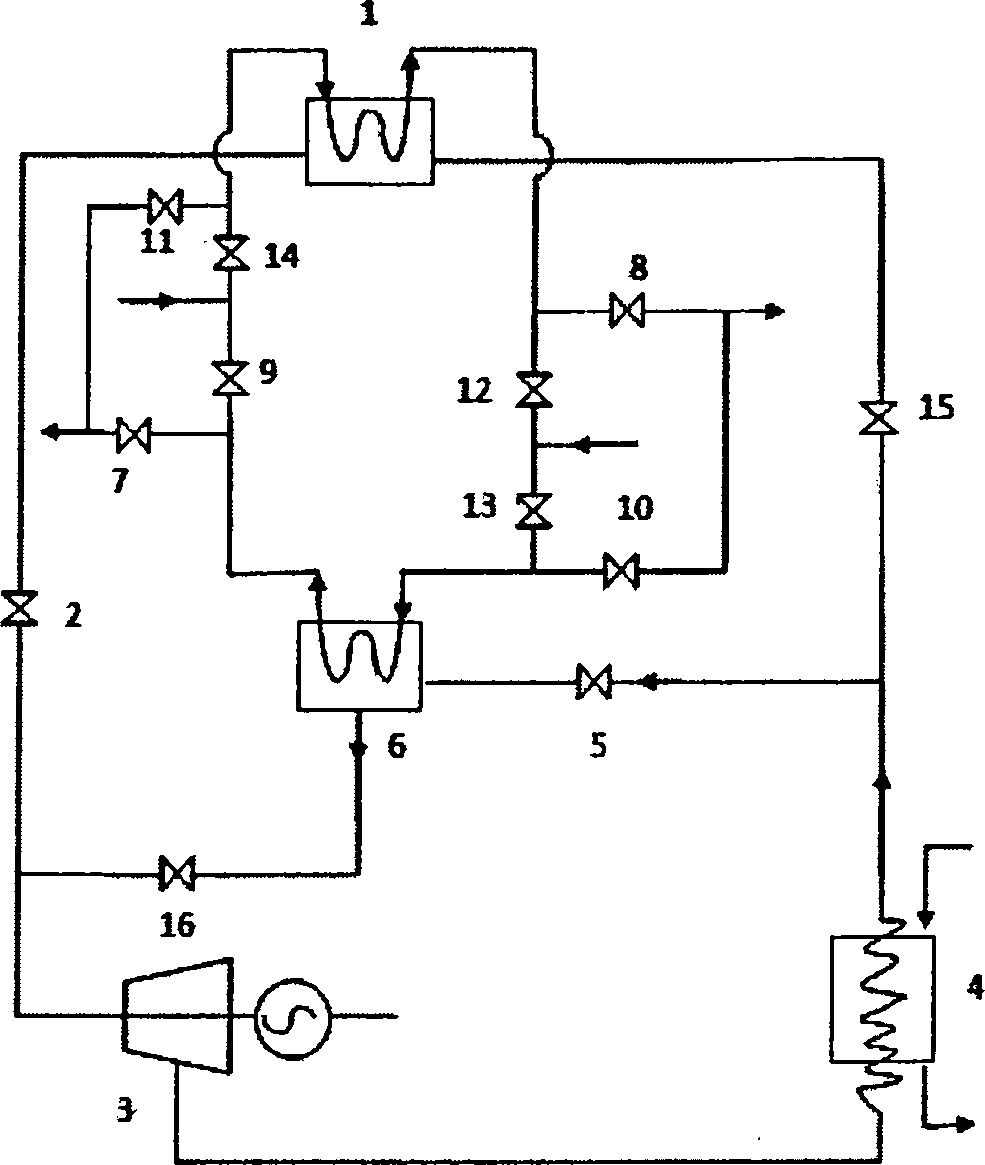

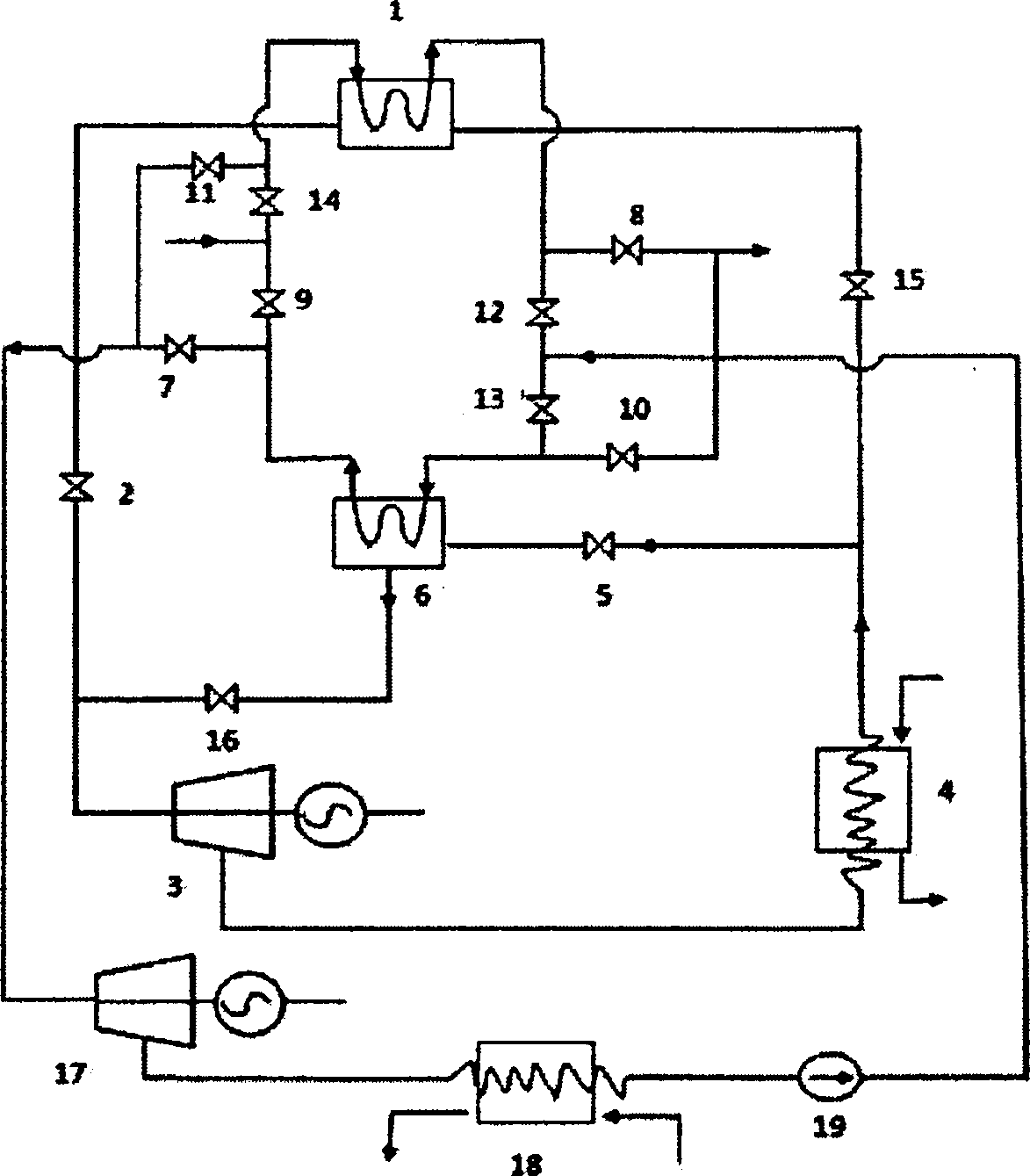

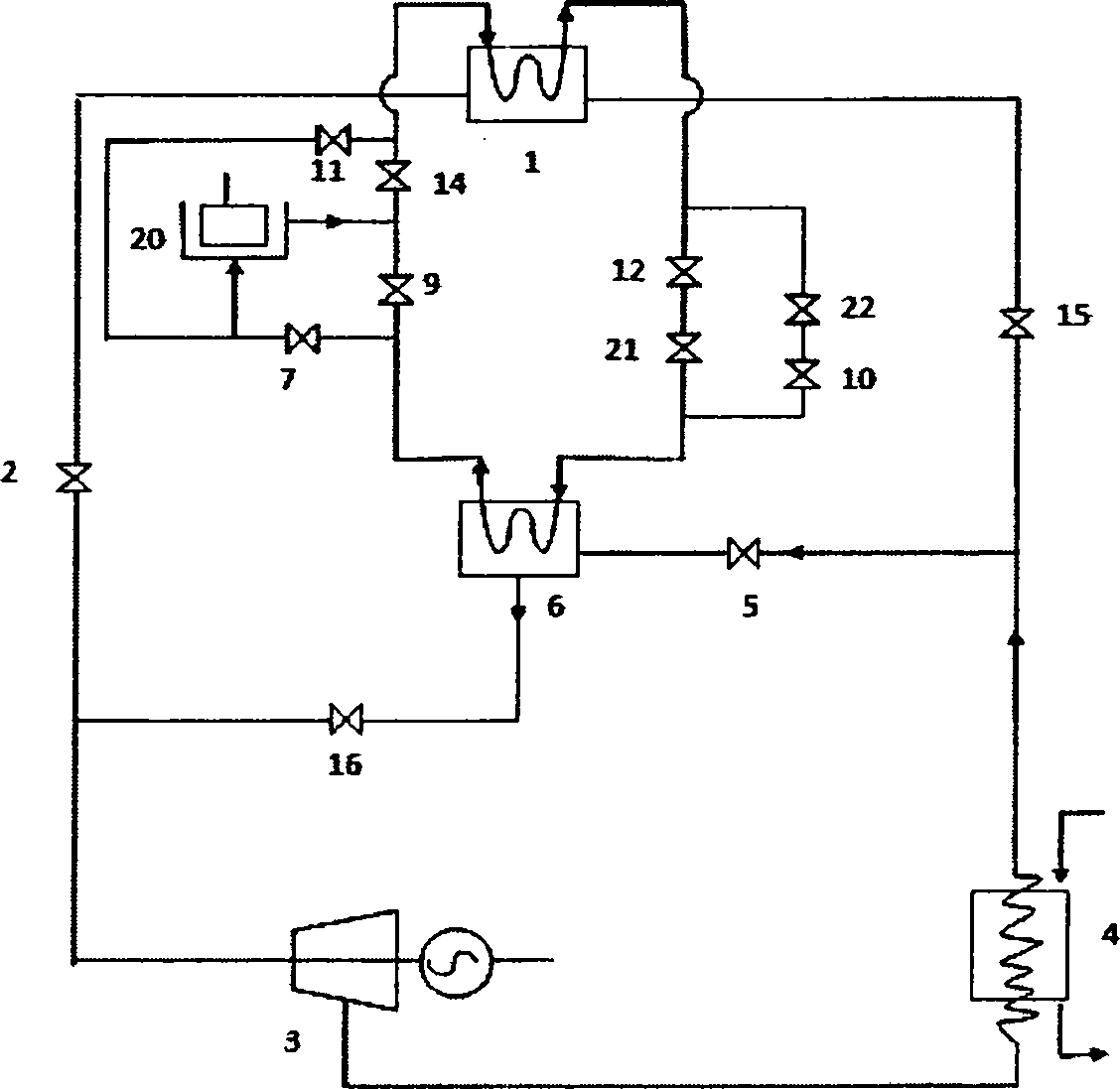

[0016] Continuous adsorption heat pump cooling power cogeneration system such as figure 1 As shown, the power cycle is divided into two paths, one is connected by adsorption bed 1, valve 2, expander 3, evaporator 4, valve 5, adsorption bed 6 and pipelines in sequence, and the other is connected by adsorption bed 6, valve 16, expander 3. The evaporator 4, valve 15, adsorption bed 1 and pipelines are connected in sequence. In the desorption stage of adsorption bed 1 and the adsorption stage of adsorption bed 6, valve 2 and valve 5 are opened, valve 16 and valve 15 are closed, the working medium is heated and desorbed by the heat source steam in the adsorption bed 1, and working medium steam is generated, and the working medium steam enters the expander 3 Expansion works and reduces pressure, discharges low-pressure exhaust steam, and low-pressure exhaust steam enters the evaporator, where the working medium liquid absorbs heat and evaporates to generate low-pressure working medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com