Precise servo mechanism friction torque testing system and testing method

A technology of servo mechanism and friction torque, which is applied in the field of precision testing of electromechanical systems, can solve the problems of low measurement accuracy and large randomness, and achieve the effects of high precision, programmed operation, and reduced mechanical structure requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below in conjunction with accompanying drawing, the present invention is described in further detail:

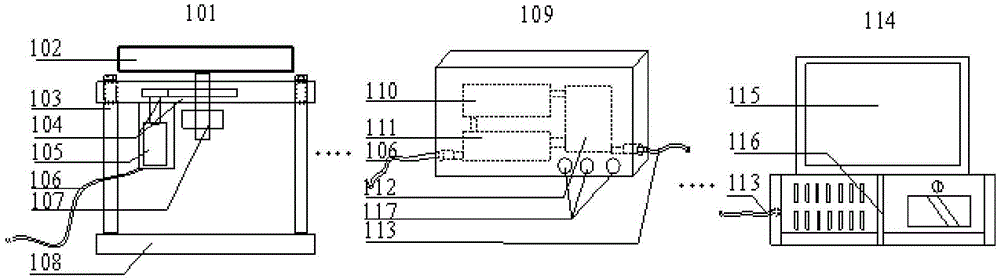

[0064] The following combination figure 1 The structure of the present invention is introduced, which is a system capable of testing the friction torque of a precision single servo mechanism. The testing system adopts a modular design and can be roughly divided into three parts, including the measured precision servo mechanism 101, the servo mechanism parameter tester 109 and the industrial computer 114 equipped with human-computer interaction software.

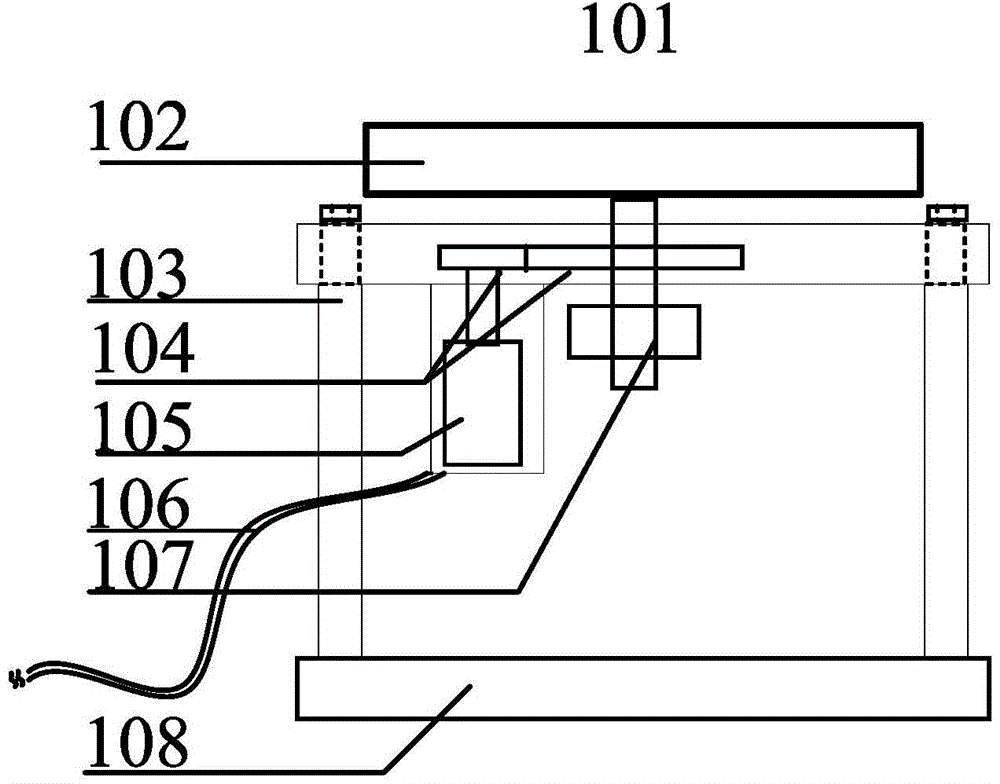

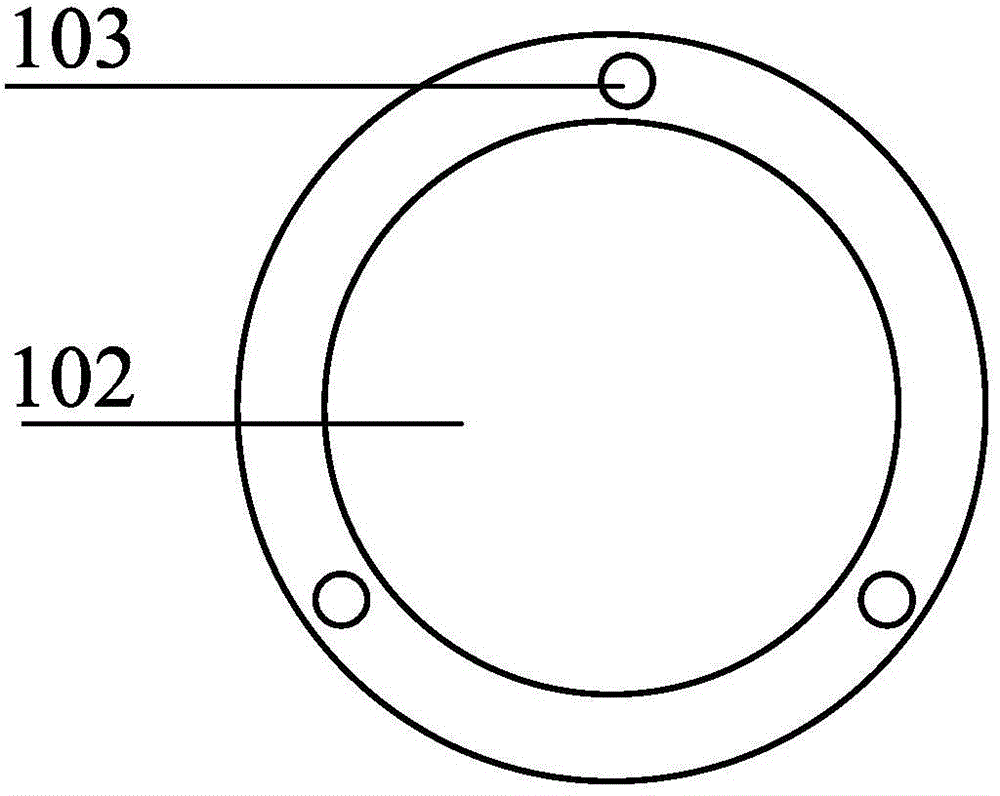

[0065] Wherein, the measured precision servomechanism 101 includes a base 108 supported by a frame fixing shaft 103, and a servo motor 105 is arranged on the base 108, and the servo motor 105 is engaged with a position sensor 107 through a transmission reduction gear set 104, and the position sensor 107 is connected to a load The disk 102 ; the servo motor 105 is connected with the servo mechanism parameter tester 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com