A kind of processing method of fresh and spicy flavor mixed chicken powder

A processing method and flavor technology, which are applied in the processing field of fresh and spicy flavor mixed chicken powder, can solve problems such as singleness of chicken powder products, and achieve the effects of rich variety, high content and pleasant matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

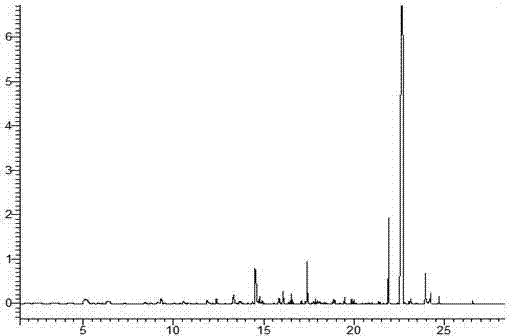

[0034] Embodiment 1 A kind of processing method of fresh and spicy flavor mixed chicken powder (low spicy flavor, see flavor map figure 1 )

[0035] (1) Preparation of chicken bone meal:

[0036] a. Cleaning: clean the chicken skeleton and drain the water on the surface;

[0037]b. Cooking: Put the cleaned chicken skeleton into a high-temperature and high-pressure cooking container at 100-125 °C and 0.15 MPa for 30-60 min;

[0038] c. Drying and crushing: Put the cooked chicken skeleton into an oven at 80~100°C for the first step of drying: hot air drying, the drying time is 1~3h, and then put the chicken skeleton into a crusher for primary crushing, The speed of the pulverizer is 25000r / min; then the chicken bone meal obtained from the first pulverization is subjected to the second drying: medium and short wave infrared drying, in which the infrared radiation wavelength is 2.4~3.0μm, and the drying temperature and time are 60~80℃ and 60℃ respectively. 20 ~ 40min, then the ...

Embodiment 2

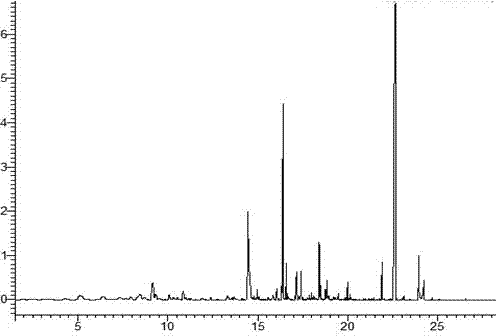

[0049] Example 2: A processing method of mixed chicken powder with fresh and spicy flavor (medium spicy flavor)

[0050] (1) Preparation of chicken bone meal:

[0051] a. Cleaning: clean the chicken skeleton and drain the water on the surface;

[0052] b. Cooking: Put the cleaned chicken skeleton into a high-temperature and high-pressure cooking container at 100-125 °C and 0.15 MPa for 30-60 min;

[0053] c. Drying and crushing: Put the cooked chicken skeleton into an oven at 80-100 °C for the first step of drying: hot air drying, the drying time is 1-3 hours, and then put the chicken skeleton in a grinder for the first crushing, crushing The speed of the machine is 25000r / min; then the chicken bone powder obtained by the first crushing is subjected to the second drying: medium and short wave infrared drying, in which the wavelength of infrared radiation is 2.4~3.0μm, and the drying temperature and time are 60~80°C and 20°C respectively. ~40min, then the dried chicken bone m...

Embodiment 3

[0064] Example 3: A processing method of mixed chicken powder with fresh and spicy flavor (high spicy flavor)

[0065] (1) Preparation of chicken bone meal:

[0066] a. Cleaning: clean the chicken skeleton and drain the water on the surface;

[0067] b. Cooking: Put the cleaned chicken skeleton into a high-temperature and high-pressure cooking container at 100-125°C and 0.15MPa for 30-60 minutes;

[0068] c. Drying and crushing: Put the cooked chicken skeleton into an oven at 80~100°C for the first step of drying: hot air drying, the drying time is 1~3h, and then put the chicken skeleton into a crusher for primary crushing, The speed of the pulverizer is 25000r / min; then the chicken bone meal obtained from the first pulverization is subjected to the second drying: medium and short wave infrared drying, in which the infrared radiation wavelength is 2.4~3.0μm, and the drying temperature and time are 60~80℃ and 60℃ respectively. 20 ~ 40min, then the dried chicken bone meal is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com