Adsorption plate used for soil heavy metal cadmium adsorption and preparation method thereof

An adsorption plate and heavy metal technology, applied in the field of pollution ecological restoration, can solve the problems affecting the comprehensive utilization value of peanuts, waste of resources, etc., and achieve the effects of good research value and application prospect, high preparation efficiency and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 A kind of preparation method of the adsorption plate that is used for soil heavy metal cadmium adsorption, comprises the following steps:

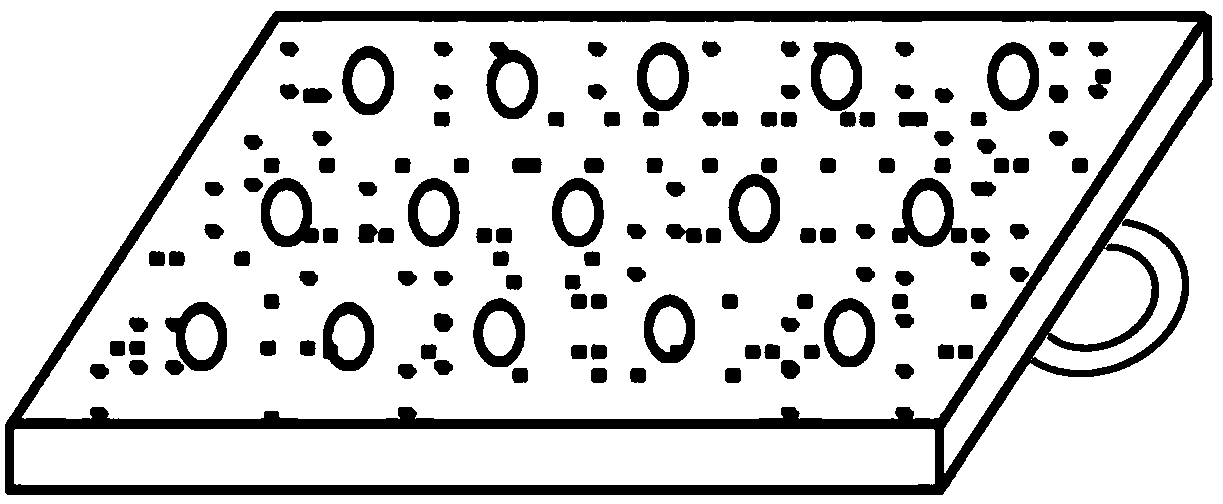

[0017] (1) Rinse the peanut shells with deionized water, and then dry them in a drying oven at 40-60°C. Finally, crush the peanut shells with a grinder and sieve them through a 40-mesh standard sieve to obtain peanut shell particles and divide them into equal parts. Two parts, one part evenly sprinkled in a square cylinder mold with pillars, the square cylinder mold includes a bottom surface and a side cylinder perpendicular to the bottom surface and sealed with the edge of the bottom surface, the bottom surface is rectangular, the length is 30cm, and the width 20cm, the bottom surface and the side cylinder form a hollow square inner cavity, the height of the inner cavity is 2cm, 15 columns parallel to each other and perpendicular to the bottom surface are evenly distributed on the bottom surface of the inner cavity, the...

Embodiment 2

[0021] Embodiment 2 An application of an adsorption plate for soil heavy metal cadmium adsorption, comprising the following steps:

[0022] (1) Rinse the peanut shells with deionized water, and then dry them in a drying oven at 40-60°C. Finally, crush the peanut shells with a grinder and sieve them through a 40-mesh standard sieve to obtain peanut shell particles and divide them into equal parts. Two parts, one part is evenly sprinkled in the square cylinder mold (same as embodiment 1) that is arranged with pillars, and the other part is stored in a dry and clean glass bottle;

[0023] (2) Sodium alginate particles are dissolved in deionized water at a temperature of 20-40°C, stirred to obtain a sodium alginate solution, wherein the mass fraction of sodium alginate is 10%;

[0024] (3) Slowly add the sodium alginate solution into the mold sprinkled with peanut shell particles, and sprinkle another portion of peanut shell particles evenly on the sodium alginate homogenate, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com