Production method of desiliconized coal ash

A production method and technology of fly ash, applied in the removal of solid waste, alumina/aluminum hydroxide, etc., can solve the problems of complex process and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

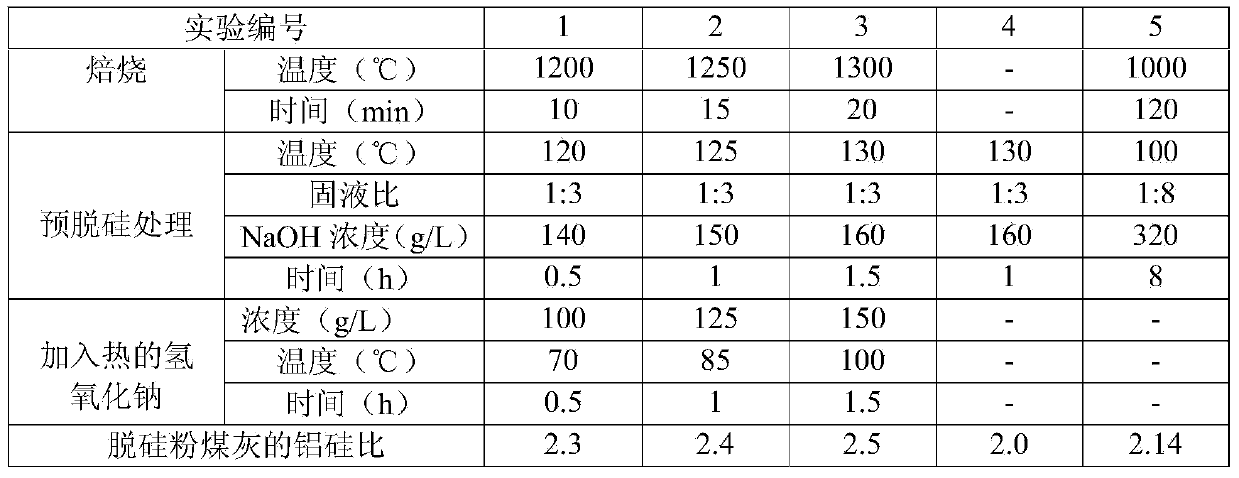

[0025] Examples 1-3 are as shown in the experiment numbers 1-3 in Table 1, and its specific production method is as described above, and each specific process parameter is shown in Table 1. With reference to the production method of the embodiment of the present invention 1-3, comparative example 4-5 is as shown in the experiment number 4-5 in table 1, and the technological process of its specific production method and each specific process parameter refer to table 1 (wherein, " -" means no such step):

[0026] Table 1

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com