Injection molding rope head and preparation method thereof

A technology of rope head and injection molding raw materials, which is applied in the field of clothing accessories, can solve the problems of affecting product quality, easy to produce deviation, waste products, etc., and achieve the effect of good adhesion, quality improvement and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

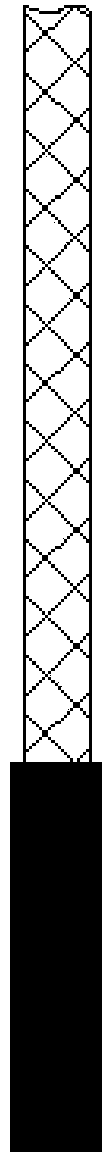

[0056] An injection-molded rope head, which is a high-hardness product, such as Figure 1-3 As shown, it includes a black rope and a transparent plastic layer. The total length is 1100mm, and the length of the plastic layer is 40mm. It has a smooth and transparent surface. The cut surface of the rope is flush with the end of the plastic layer.

[0057] Prepared by the following method:

[0058] (1) Ingredients:

[0059] Weigh the raw materials with the weight ratio of plastic raw materials: functional additives = 100:5, mix them evenly in the mixer, and then complete the batching, and obtain the injection molding raw materials. If it is 80D, add the injection molding raw material into the hopper of the machine and set it aside.

[0060] Among them: the plastic raw material is styrene-acrylonitrile copolymer, its Shore hardness is 80D, and its density is 1.06~1.08g / cm 3 , transparency 88% to 92%, refractive index 1.57.

[0061] The functional additive is polyperfluoroethyle...

Embodiment 2

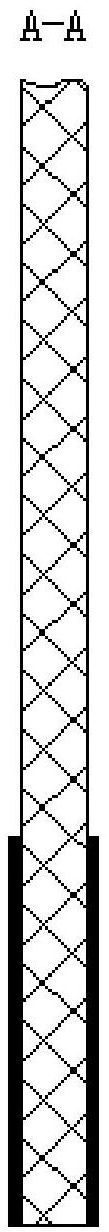

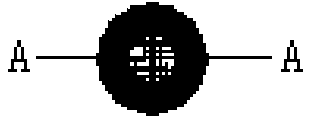

[0070] An injection-molded rope head, which is a high-hardness product, such as Figure 4-Figure 6 As shown, it includes a black rope and a transparent plastic layer. The total length is 1100mm, and the length of the plastic layer is 40mm. It has the effect of smooth surface, transparency and end sealing.

[0071] Prepared by the following method:

[0072] (1) Ingredients: Same as in Example 1, the peeling force between the plastic end seal and the section formed by the injection molding raw material is 6N / 25mm.

[0073] (2) traction positioning: same as embodiment 1.

[0074] (3) Injection molding: the same as in Example 1.

[0075] (4) Cutting:

[0076] Use an automatic beer cutting machine to cut the plastic layer and the rope body at a distance of 1-1.5 mm from the end of the plastic layer.

[0077] (5) Glue filling and sealing:

[0078] Put the above-mentioned rope end with 1-1.5 mm of plastic layer cut off into the mold cavity again, and form a plastic sealing part ...

Embodiment 3

[0080] An injection-molded rope end, which is a medium-hard product, such as Figure 7-Figure 9 As shown, it includes a black rope and a solid-color plastic layer of luminous powder. The total length is 1100mm, and the length of the plastic layer is 40mm. It has the effect of smooth surface, luminous and loose ends.

[0081] Prepared by the following method:

[0082] (1) Ingredients:

[0083] Weigh the raw materials with the weight ratio of plastic raw materials: functional additives: processing additives = 100:1:0.1, mix them evenly in the mixer, and then complete the batching to obtain injection molding raw materials. The peeling force of the injection molding raw materials and ropes after bonding It is 4N / 25mm, put the injection molding raw material into the hopper of the machine, and set it aside.

[0084] Among them: the plastic raw material is polyethylene, its Shore hardness is 45D, and its density is 0.86~0.96g / cm 3 .

[0085] The functional additive is luminous po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com