Multi-axis bridge frame type glass online stacking machine about stacking manipulator

A technology of manipulators and stackers, which is applied in the fields of glass machinery, degree-of-freedom series robots and automatic control, can solve problems such as failure to meet high-end requirements, poor surface quality, and long stacking cycles, and solve the dangers of workers' operations, Inexpensive, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In conjunction with the accompanying drawings, the present invention is described in detail, wherein the technology of the manufacturing technology of the stacker including the control system is clear to those skilled in the art:

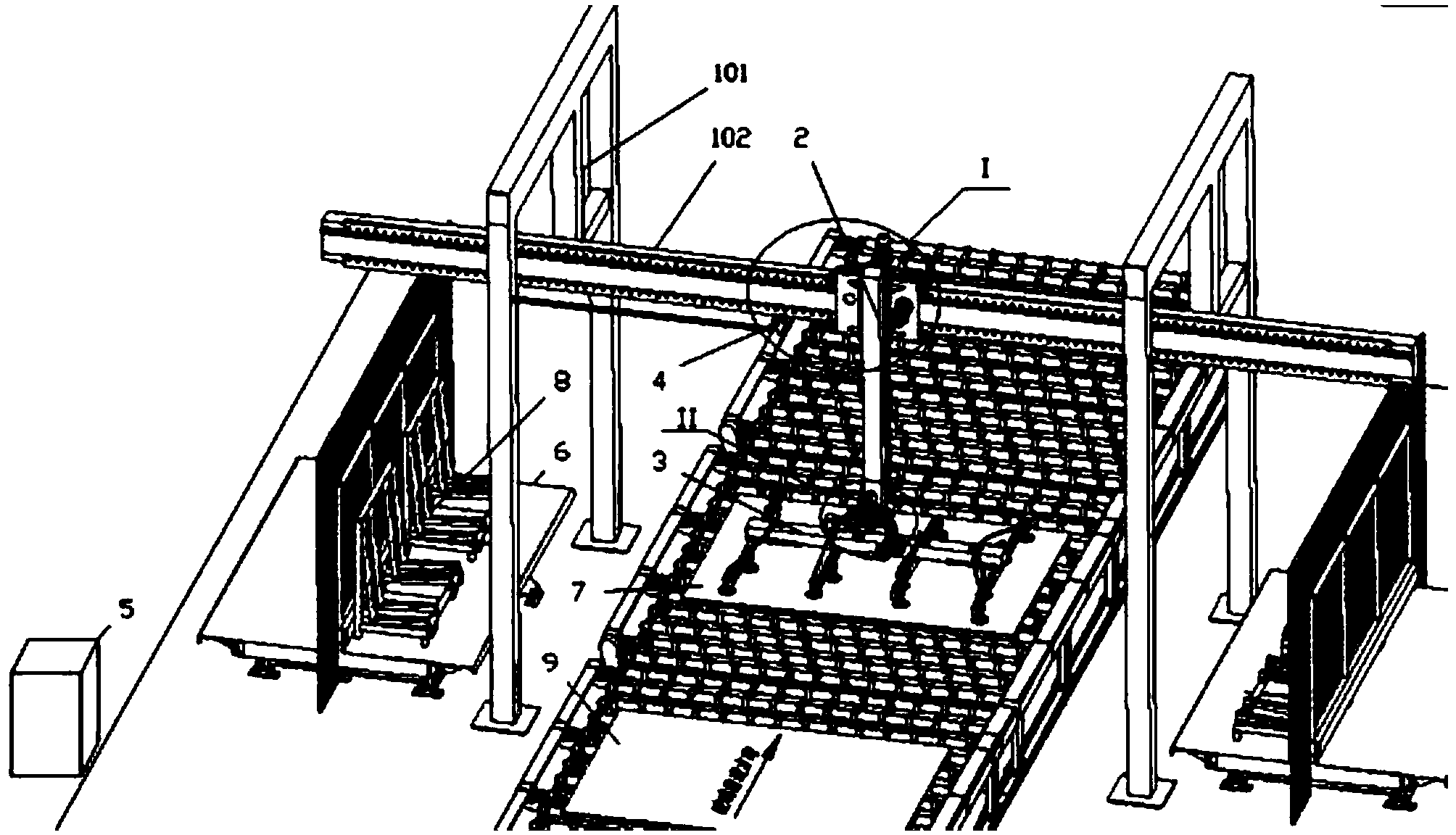

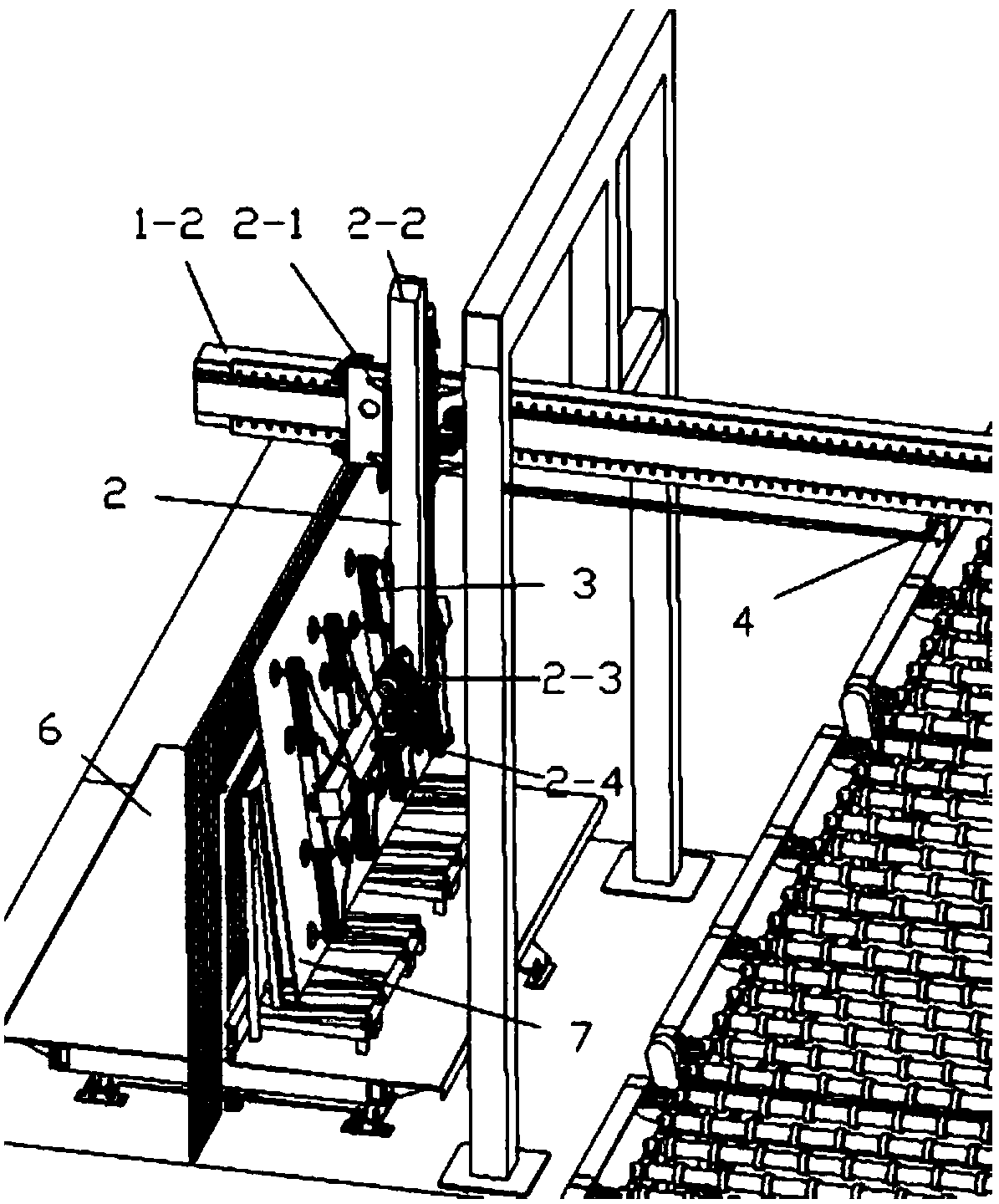

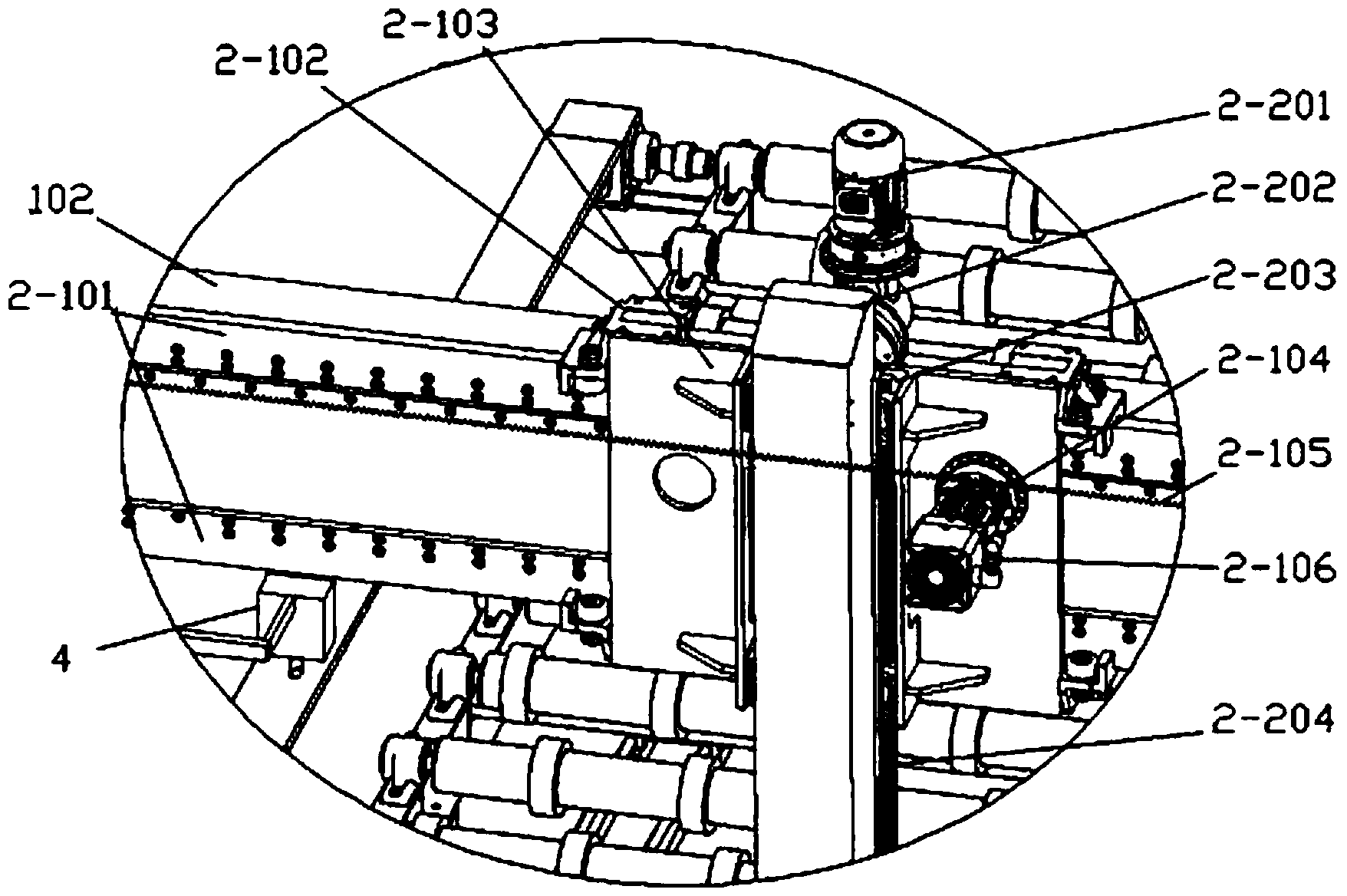

[0028] The present invention can realize automatic stacking, such as figure 1 , figure 2 As shown, the present invention consists of frame 1, main frame 2 (comprising: horizontal travel axis 2-1, vertical lift axis 2-2, first rotation axis 2-3, second rotation axis 2-4), multifunctional vacuum grip It is composed of system 3, visual positioning system 4, and control system 5; others are production line devices: pallet carrier 6, glass pallet 8, conveying roller table 9, and glass 7.

[0029]The frame 1 straddles the glass production line, and its appearance is a double-door cantilever structure at both ends. The door-shaped lifting point structure is beneficial to the overall rigidity of the walking beam support 102 and is conducive to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com