Sewage treatment device based on 3D printing biological stuffing

A sewage treatment device and 3D printing technology, applied in biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve problems such as high surface roughness and complex structure, and achieve uniform air distribution , Stable inner cavity temperature, easy to attach effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

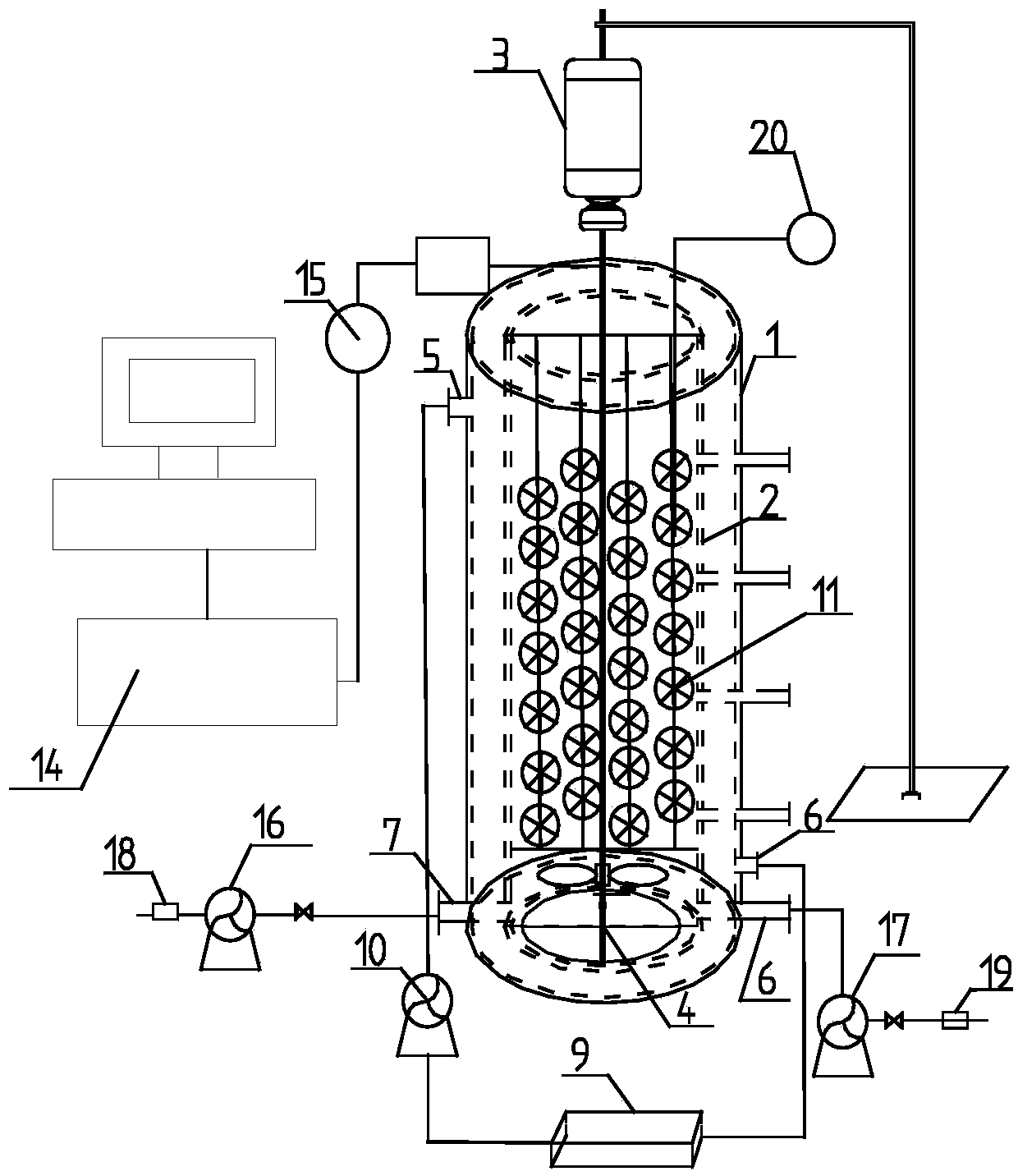

[0039] The present invention is a sewage treatment device based on 3D printing biological filler, which includes a cylinder made of plexiglass. The cylinder includes an inner chamber 2, a shell 1 and a cylinder cover. Both the inner chamber 2 and the outer shell 1 are cylinders, and the height and diameter The ratio is 3:1, and there are multiple exhaust holes on the cylinder cover. The inside of the inner chamber 2 is a reaction layer, and a water bath layer is formed between the inner chamber 2 and the outer shell 1 .

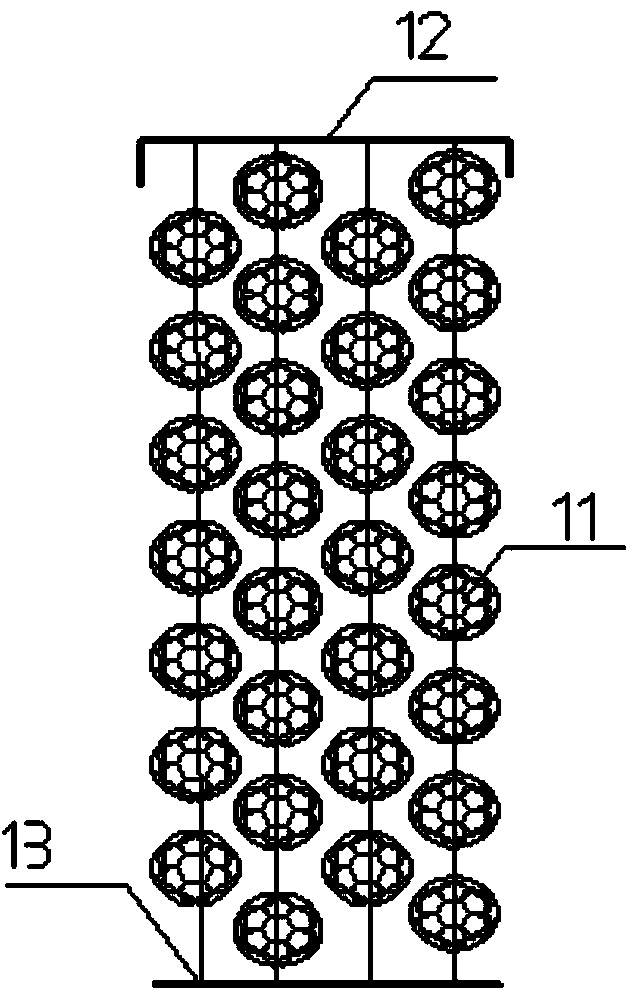

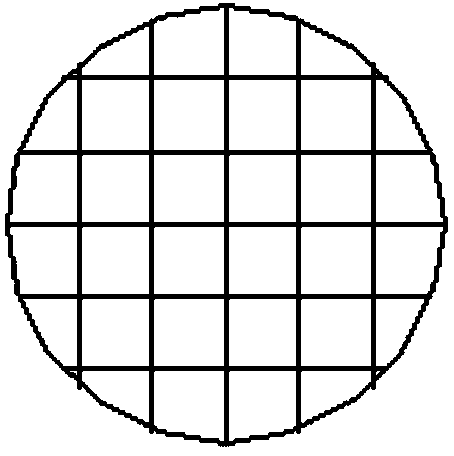

[0040] The filler 11 placed in the reaction layer has a structure of a three-dimensional hollow honeycomb-like sphere with 5 sides and a diameter of 30mm. And the filler 11 is made of plastic ultrafine spherical powder through 3D printing technology. The plastic ultrafine spherical powder adopts a size of 300 mesh. The prepared filler 11 sphere has a better surface roughness and a faster biofilm formation quick. The packing 11 is placed inside the inner cavit...

Embodiment 2

[0044] The present invention is a sewage treatment device based on 3D printing biological filler, which includes a cylinder made of organic PVC. The cylinder includes an inner chamber 2, a shell 1 and a cylinder cover. The ratio is 2:1, and there are multiple exhaust holes on the cylinder cover. The inside of the inner chamber 2 is a reaction layer, and a water bath layer is formed between the inner chamber 2 and the outer shell 1 .

[0045] The filler 11 placed in the reaction layer is a three-dimensional hollow honeycomb-like sphere with a diameter of 50 mm. And the filler 11 is made of plastic ultrafine spherical powder through 3D printing technology. The plastic ultrafine spherical powder adopts a size of 500 mesh. quick. The packing 11 is placed inside the inner cavity 2 in a hanging manner, and the packing 11 is vertically suspended between the upper and lower grids (12, 13). 11 are equally spaced; and the lower grid 13 is matched with the inner edge of the inner cavi...

Embodiment 3

[0049] The present invention is a sewage treatment device based on 3D printing biological filler, which includes a cylinder made of organic PVC. The cylinder includes an inner chamber 2, a shell 1 and a cylinder cover. The ratio is 5:1, and there are multiple exhaust holes on the cylinder cover. The inside of the inner chamber 2 is a reaction layer, and a water bath layer is formed between the inner chamber 2 and the outer shell 1 .

[0050] The filler 11 placed in the reaction layer is a three-dimensional hollow honeycomb-like sphere with a diameter of 70 mm. And the filler 11 is made of plastic ultrafine spherical powder through 3D printing technology. The plastic ultrafine spherical powder adopts the size of 800 mesh. quick. The packing 11 is placed inside the inner cavity 2 in a hanging manner, and the packing 11 is vertically suspended between the upper and lower grids (12, 13). 11 are equally spaced; and the lower grid 13 is matched with the inner edge of the inner ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com