Method for improving glycol product quality

A product quality, ethylene glycol technology, applied in chemical instruments and methods, bulk chemical production, organic compound preparation, etc., can solve problems such as complex operation, high catalyst production cost, and difficulty in large-scale reactors, and achieve good results The effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

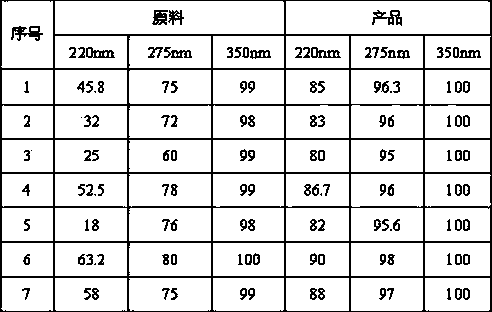

[0021]Put the catalyst with alumina as the carrier, the content of metal nickel as 20% of the weight of the carrier, and the content of magnesium as the metal additive as 1.5% of the weight of the carrier into the gas-liquid phase fixed-bed reactor, and the volume content of hydrogen gas is 90%. The mixed gas of hydrogen and nitrogen, at a pressure of 0.3MPa, a maximum temperature of 450°C, and a volumetric space velocity of 1000h -1 Under the conditions of the reduction treatment for 12 hours, after the reduction is completed, it is lowered to the reaction temperature, and then ethylene glycol product raw materials with a purity of 99.8% are respectively introduced from the bottom of the reactor (ultraviolet permeability of the raw materials) obtained by hydrogenation of dimethyl oxalate The light rate is shown in Table 1) and hydrogen, at a reaction temperature of 80°C, a reaction pressure of 0.4MPa, and an hourly space velocity of ethylene glycol liquid of 15h -1 , The volu...

Embodiment 2

[0024] Load the gas-liquid phase fixed-bed reactor with alumina as the carrier, the metal nickel content as 10% of the carrier weight, the metal palladium content as 0.8% of the carrier weight, and the metal additive barium content as 0.8% of the carrier weight , feed pure hydrogen, at a pressure of 0.1MPa, a maximum temperature of 500°C, and a volumetric space velocity of 800h -1 Under the conditions of the reduction treatment for 8 hours, after the reduction is completed, it is lowered to the reaction temperature, and then the ethylene glycol product raw materials with a purity of 99.2% are respectively introduced into the reactor from the top of the reactor (the ultraviolet permeability of the raw material The light rate is shown in Table 1) and hydrogen, at a reaction temperature of 90°C, a reaction pressure of 0.6MPa, and an hourly space velocity of ethylene glycol liquid of 10h -1 , hydrogen and raw material volume ratio of 50 under the condition of contact with the cata...

Embodiment 3

[0027] Put alumina as the carrier, the metal nickel content is 40% of the carrier weight, the metal additive magnesium content is 1% of the carrier weight, and the metal additive molybdenum content is 0.1% of the carrier weight. The catalyst is loaded into a gas-liquid phase fixed bed In the reactor, a mixed gas of hydrogen and nitrogen with a hydrogen volume content of 70% is introduced, at a pressure of 0.6MPa, a maximum temperature of 480°C, and a volume space velocity of 1500h -1 Under the conditions of the reduction treatment for 16 hours, after the reduction is completed, it is lowered to the reaction temperature, and then the ethylene glycol product raw material with a purity of 99.9% is respectively introduced from the bottom of the reactor (the ultraviolet The light transmittance is shown in Table 1) and hydrogen, at a reaction temperature of 95°C, a reaction pressure of 0.5MPa, and an hourly space velocity of ethylene glycol liquid of 40h -1 , The volume ratio of hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com