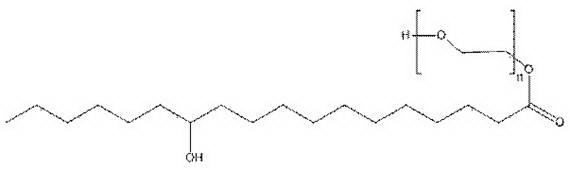

Solid-phase load method for synthesizing polyethylene glycol-12-hydroxystearate

A technology of hydroxystearate and polyethylene glycol, which is applied in the field of synthesizing polyethylene glycol-12-hydroxystearate, can solve problems such as difficult control, incomplete solution of mono- and di-ester mixing, violent reaction, etc. To achieve the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Raw materials used:

[0054] Chloromethylated polystyrene crosslinking resin, CAS No. 55844-94-5, 1% divinylbenzene crosslinking, commercially available.

[0055] 12-Hydroxystearate, CAS No. 106-14-9, commercially available.

[0056] Polyethylene glycol 400 and other inorganic and organic reagents are commercially available analytically pure commodities, and were used directly without any treatment unless otherwise specified.

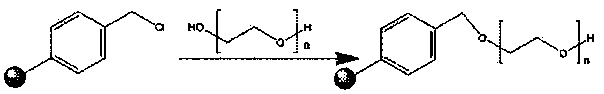

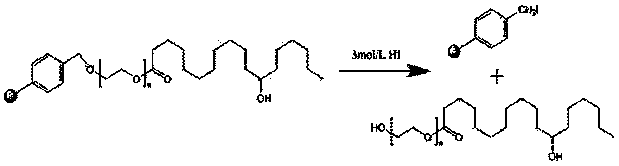

[0057] Step a: Take 200g of polyethylene glycol 400, absorb and dehydrate through anhydrous calcium sulfate and 4A molecular sieve, filter, and vacuum-dry to obtain anhydrous polyethylene glycol for later use; take 20g of chloromethylated polystyrene crosslinking resin, and use 300ml After the anhydrous dioxane is swelled, put it into 100g of anhydrous polyethylene glycol at 0-5°C, and feed in batches while stirring. All the resins are added in 30 minutes, and then 5g of cesium carbonate is added, and the reaction is stirred for 2 hours; After ...

Embodiment 2

[0064] Except that the amount of anhydrous polyethylene glycol in step a is 200 g, the amount of 12-hydroxystearic acid in step c is 440 g, and the pH=10 is adjusted in step d, the rest are the same as in Example 1. Finally, 41.2 g of the product polyethylene glycol-12-hydroxystearate was obtained, with a yield of 98%, and a pale yellow appearance.

Embodiment 3

[0069] Example 3 Mono- and Diester Inspection

[0070] By measuring the saponification value of the sample, it can be judged whether the sample is a monoester.

[0071] Saponification value is defined as the number of milligrams of potassium hydroxide required to saponify 1 gram of sample. Saponification value indicates the number of milligrams of potassium hydroxide consumed to neutralize and saponify 1g of substance under specified conditions.

[0072] Detection method: according to the records in Appendix VII H of "Chinese Pharmacopoeia 2010 Edition Part Two".

[0073] Get an appropriate amount of the test product (its weight (g) is approximately equivalent to 250 / the maximum saponification value of the test product, and the sample size in this embodiment is 1g), accurately weighed, put in a 250ml Erlenmeyer flask, and accurately add 0. 25ml of 5mol / L potassium hydroxide ethanol solution, heat and reflux for 30 minutes, then wash the inner wall of the condenser and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com