Method of recycling silver-containing soldering tin slag

A recycling method and tin slag technology, which is applied in the field of metallurgy and chemical industry, can solve problems such as low economic value and environmental pollution, and achieve the effects of increased economic benefits, high metal recovery rate, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

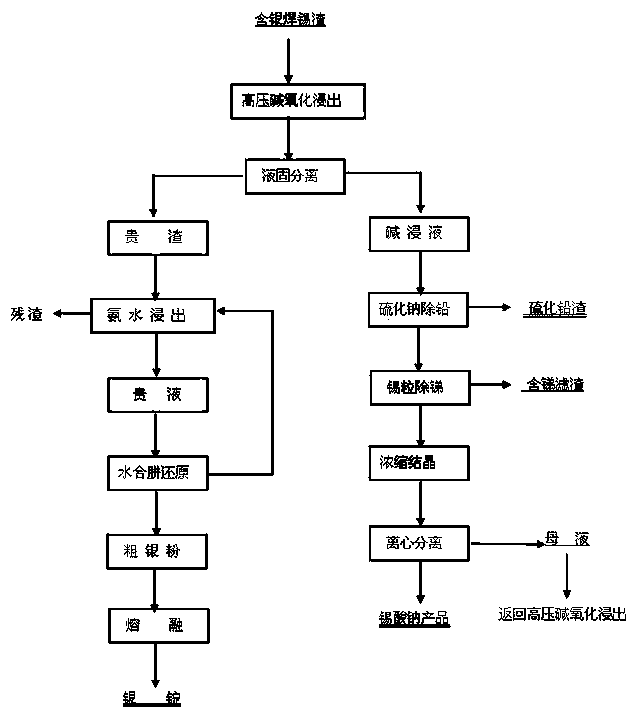

[0025] The operation steps include: high-pressure alkali oxidation leaching, solid-liquid separation, purification and impurity removal, concentrated crystallization, precious slag and silver separation.

[0026] 1. High-pressure alkali oxidation leaching: Put the solder slag containing Sn55-63%, Pb30-36%, Ag0.1-0.2% into the autoclave, and add the impregnation solution composed of sodium hydroxide, sodium nitrate and water at the same time, Control the mass ratio of solder slag to sodium hydroxide and sodium nitrate to be 1:0.75~0.8:0.15, and the liquid-solid ratio is 8~10:1. After the feeding is completed, open the air inlet, fill in oxygen, adjust the pressure in the kettle to 1.8-2.0MPa, then close the air inlet valve, and heat up while stirring. The reaction process maintains the temperature in the kettle at 150-180°C and the pressure at 1.8-2.0 MPa, keep stirring for 1-2 hours to complete the leaching, then cool and discharge.

[0027] The chemical reaction formula of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com