Switching-on and switching-off integrated mechanism of outdoor high-voltage vacuum circuit breaker

A vacuum circuit breaker and high-voltage technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problem of preventing secondary closing interlock device damage, difficult to ensure the accuracy of positioning grooves, and difficult to ensure assembly quality. and other problems, so as to ensure the effects of misoperation and damage to components, simplify the assembly process, and improve the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

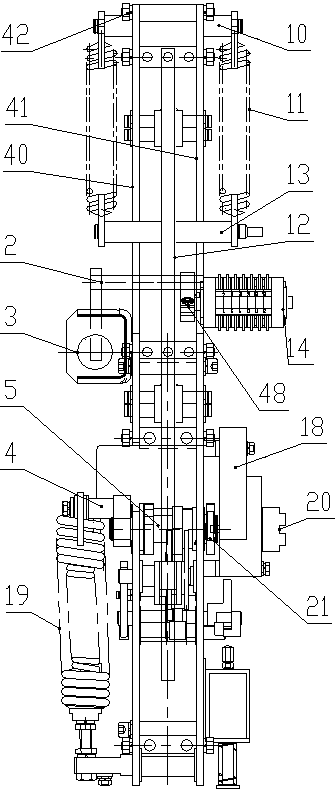

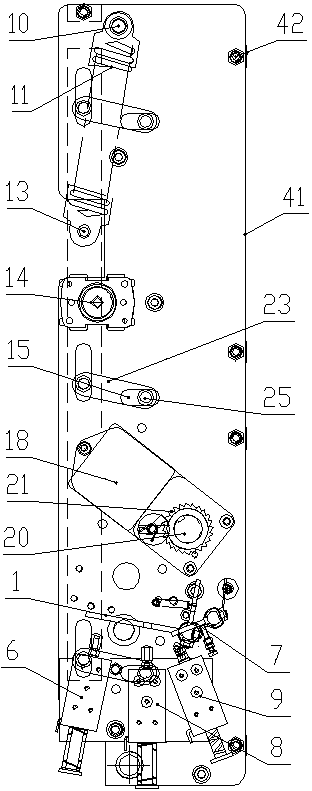

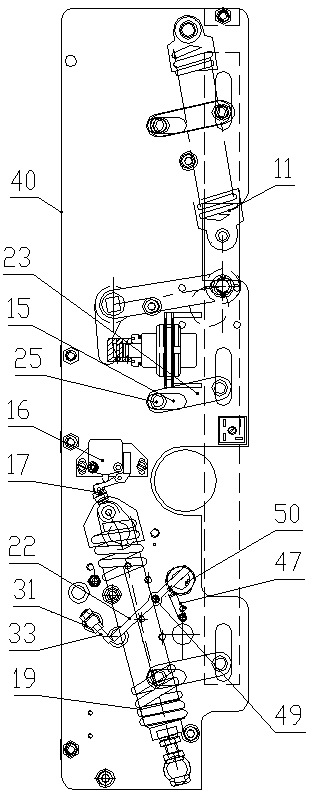

[0024] like Figure 1-Figure 6As shown in the figure, the integrated mechanism of closing and opening of the outdoor high-voltage vacuum circuit breaker of the present invention includes a frame composed of a left clamp plate 40, a right clamp plate 41 and a fixing column 42, and the fixing column 42 is arranged between the left clamp plate 40 and the right clamp plate 41. , the fixing column 42 is used to connect the left splint 41 and the right splint 42 and limit the distance between them, and the frame is provided with a closing system, an opening system, an interlocking device, a signal output device, an electrical control element, an output arm and The driving spindle 12 is arranged in parallel between the left clamping plate 40 and the right clamping plate 41. The output arm is composed of a connecting arm 43, a first linkage arm 44 and a second linkage arm 45 arranged in a Y-shaped structure. The connecting arm 43 , The connection between the inner ends of the first li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com