Fluorite collecting agent and preparing method of fluorite collecting agent

A collector and fluorite technology, applied in solid separation, flotation, etc., can solve the problems of low fluorite fluorite grade, unsatisfactory collection effect, high cost of collector, etc., to improve the fluorite The effect of flotation recovery rate, good marketing value and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

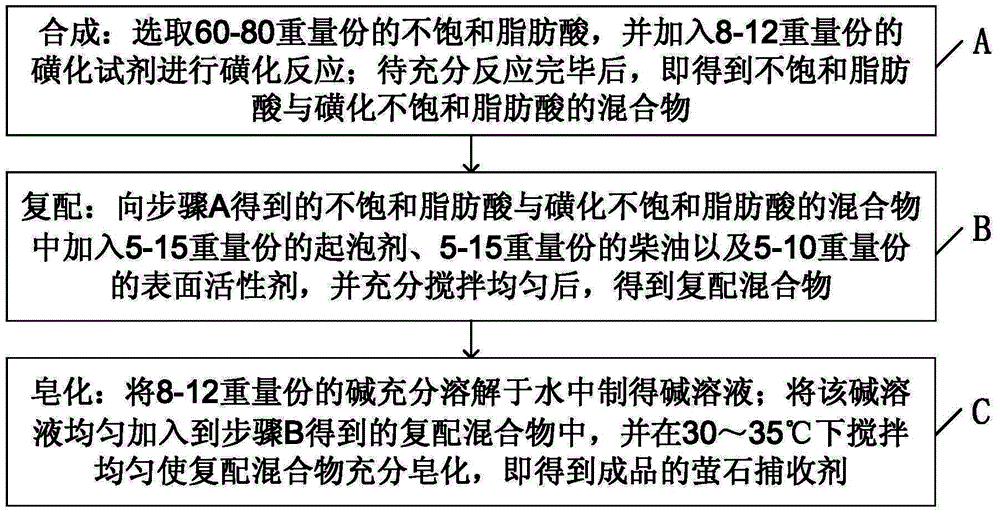

[0044] (2) A kind of preparation method of fluorite collector

[0045] Such as figure 1 Shown, a kind of preparation method of fluorite collector, it specifically can comprise the steps:

[0046] Step A, synthesis: select 60-80 parts by weight of unsaturated fatty acid, and add 8-12 parts by weight of sulfonating reagent to carry out sulfonation reaction; after the full reaction is completed, the mixture of unsaturated fatty acid and sulfonated unsaturated fatty acid is obtained mixture.

[0047] Step B, Compounding: Add 5-15 parts by weight of foaming agent, 5-15 parts by weight of diesel oil and 5-10 parts by weight of surface active agent, and after fully stirring uniformly, a compound mixture is obtained.

[0048] Step C, saponification: Fully dissolve 8-12 parts by weight of alkali in water to prepare an alkali solution; uniformly add the alkali solution to the compound mixture obtained in step B, and stir evenly at 30-35°C to make the compound The mixture is fully sa...

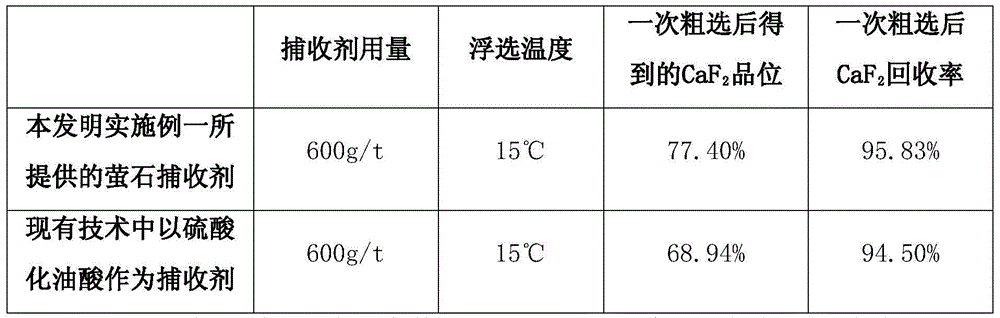

Embodiment 1

[0058] Select 72 parts by weight of industrial oleic acid into the reactor, add 8 parts by weight of concentrated sulfuric acid, and stir at 30°C for 1 to 1.5 hours, so that the sulfonation reaction is fully complete, and the reaction solution becomes viscous and gradually colored. get darker. At this time, add 5 parts by weight of MIBC, 10 parts by weight of 0# diesel oil and 5 parts by weight of NP-10 surfactant in the reactor, and fully stir for 1 hour at 30 ° C to obtain a uniformly stirred compound mixture . Dissolve 10 parts by weight of solid sodium hydroxide in 200 parts by weight of water to obtain an aqueous sodium hydroxide solution; slowly add the aqueous sodium hydroxide solution into the reactor, and stir evenly at 30-35°C to fully saponify it, that is A high-selectivity fluorite collector resistant to low temperature is obtained.

[0059] The composition of this fluorite collector can include: the industrial oleic acid of 48 parts by weight, the sulfated oleic...

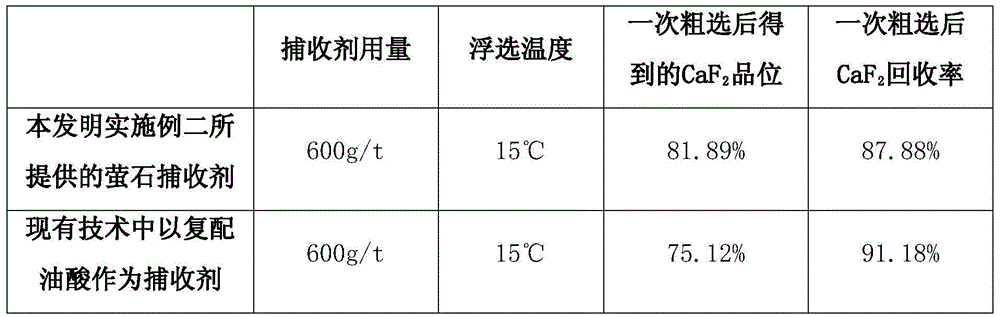

Embodiment 2

[0067] Choose 72 parts by weight of tall oil and put it into the reactor, and after the temperature is raised to 90°C, add 30 parts by weight of the concentration of 30% sodium bisulfite solution in the reactor, and then keep the temperature at 90°C React for 2 to 3 hours to make the sulfonation reaction fully complete. At this point, add 6 parts by weight of 2# oil, 12 parts by weight of 0# diesel oil and 4 parts by weight of NP-10 surfactant, and fully stir for 1 hour at 50 ° C to obtain a well-stirred complex With the mixture. Dissolve 10 parts by weight of solid sodium hydroxide in 179 parts by weight of water to obtain an aqueous solution of sodium hydroxide; slowly add the aqueous solution of sodium hydroxide to the reactor, and stir evenly at 30-35°C to fully saponify it, that is A high-selectivity fluorite collector resistant to low temperature is obtained.

[0068] The composition of this fluorite collector can include: 42 parts by weight of tall oil, 30 parts by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com