Production method of small-aperture ultrathin-walled high-frequency welded aluminum alloy pipe for heat pump

A high-frequency welding, aluminum alloy tube technology, used in high-frequency current welding equipment, welding equipment, metal processing equipment, etc. The pressure resistance does not meet the requirements and other problems, to achieve the effect of improving the production efficiency, reducing the material cost, and excellent pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

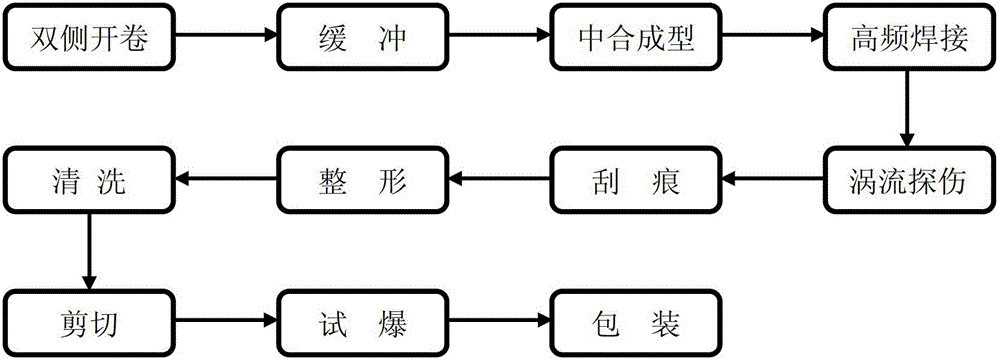

[0026] Such as figure 1 As shown, the production method flow process of the small-diameter welded pipe of the present embodiment is as follows:

[0027] (1) The aluminum alloy strip is made of a four-layer double-sided anti-corrosion structural aluminum alloy material with a thickness of 0.35mm produced by Shandong Weifang Sanyuan Aluminum Industry Co., Ltd. The four-layer double-sided anti-corrosion structural aluminum alloy material includes the first layer, the second Layer, third layer and fourth layer, the first layer is the brazing layer, choose 4045 aluminum alloy; the second layer is the anti-corrosion layer, choose 7072 aluminum alloy; the third layer is the core layer, choose 3003 aluminum alloy ; The fourth layer is the anti-corrosion layer, which is made of 7072 aluminum alloy.

[0028] (2) Double-sided decoiling step: the coiled aluminum alloy strip is uncoiled by applying force from both sides through the uncoiler.

[0029] (3) Buffer step: used to control the ...

Embodiment 2

[0040] The production method flow process of the small-caliber welded pipe of the present embodiment is as follows:

[0041] (1) The aluminum alloy strip is made of a four-layer double-sided anti-corrosion structural aluminum alloy material with a thickness of 0.8mm produced by Shandong Weifang Sanyuan Aluminum Industry Co., Ltd. The four-layer double-sided anti-corrosion structural aluminum alloy material includes the first layer, the second Layer, third layer and fourth layer, the first layer is the brazing layer, choose 4045 aluminum alloy; the second layer is the anti-corrosion layer, choose 7072 aluminum alloy; the third layer is the core layer, choose 3003 aluminum alloy ; The fourth layer is the anti-corrosion layer, which is made of 7072 aluminum alloy.

[0042] (2) Double-sided decoiling step: the coiled aluminum alloy strip is uncoiled by applying force from both sides through the uncoiler.

[0043] (3) Intermediate molding step: Send the aluminum alloy strip into t...

Embodiment 3

[0049] The production method flow process of the small-caliber welded pipe of the present embodiment is as follows:

[0050] (1) The aluminum alloy strip is made of a four-layer double-sided anti-corrosion structural aluminum alloy material with a thickness of 0.35mm produced by Shandong Weifang Sanyuan Aluminum Industry Co., Ltd. The four-layer double-sided anti-corrosion structural aluminum alloy material includes the first layer, the second Layer, third layer and fourth layer, the first layer is the brazing layer, choose 4045 aluminum alloy; the second layer is the anti-corrosion layer, choose 7072 aluminum alloy; the third layer is the core layer, choose 3003 aluminum alloy ; The fourth layer is the anti-corrosion layer, which is made of 7072 aluminum alloy.

[0051] (2) Double-sided decoiling step: the coiled aluminum alloy strip is uncoiled by applying force from both sides through the uncoiler.

[0052] (3) Intermediate molding step: Send the aluminum alloy strip into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com