Method for separating ethanol-water-cumene mixed solution by single-side extraction and azeotropic distillation

A technique of azeotropic distillation and extractive distillation, which is applied in the direction of distillation purification/separation, chemical instruments and methods, and preparation of organic compounds, and can solve the difficult separation and extraction of ethanol, cumene, and cumene sulfonic acid High production costs, waste of ethanol and cumene, etc., to achieve the effects of reducing energy consumption, simplifying the production process, and utilizing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention are described in further detail below through specific examples, but it is necessary to point out that the following examples are only used to describe the content of the invention and do not constitute a limitation on the protection scope of the present invention. Anyone familiar with the profession can make various changes and equivalent substitutions to the specific embodiments described in the present invention without departing from the purpose and scope of the present invention, including but not limited to process conditions such as raw material liquid composition, flow rate, temperature, etc. . Unless otherwise specified, the percentages in the specification are mass percentages.

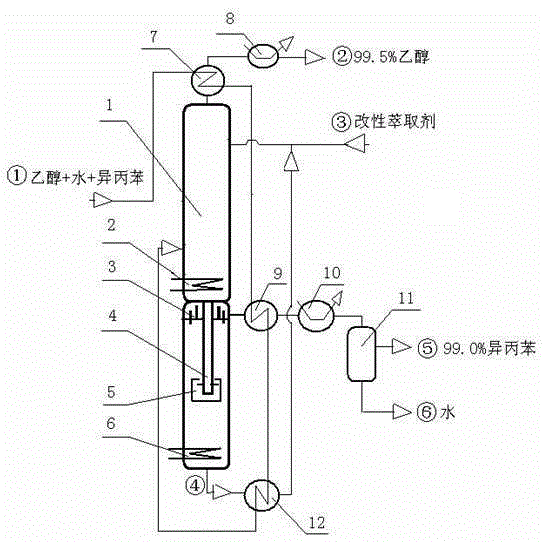

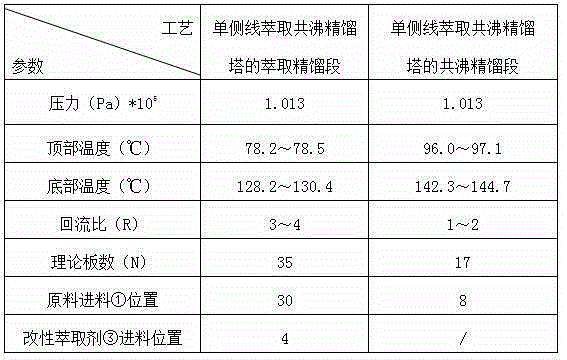

[0019] According to the method for separating ethanol, water and cumene mixed solution by single-side line extraction azeotropic distillation according to the present invention, the process flow and device are referred to figure 2 , Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com