Rare earth europium complex and preparation method for europium red light transparent film based on PVB matrix

A technology of rare earth complexes and europium complexes, which is applied in the field of synthesis of new europium complexes, can solve problems such as poor film transparency and insufficient luminous film strength, and achieve improved coordination ability, excellent luminous efficiency, and good photostability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Accurately weigh 0.0495g PVB, 0.0005g Eu(TTA) 2 Tpy-OCH 3 , Dissolve Eu(TTA) with an appropriate amount of DMF (N-N-dimethylformamide) 2 Tpy-OCH 3 , Pour the dissolved solution into a beaker, then add 20ml of absolute ethanol and 30ml of THF to make a 1g / L solution. Drop an appropriate amount of the solution into a watch glass with a dropper, and let the solvent evaporate naturally at room temperature.

[0042] Use PVB as a substrate to prepare a film. If the solvent volatilizes faster, the prepared film will turn white, and PVB is not easy to form a film, and it takes a long time to form a film. Therefore, choose to volatilize at room temperature for 36 hours to prepare the complex Eu(TTA) 2 Tpy-OCH 3 The mass is 1% PVB red light film.

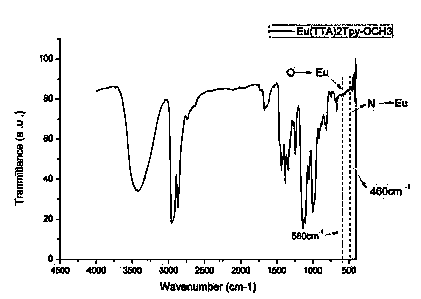

[0043] attached figure 1 In , the typical asymmetry of the carbonyl group in TTA occurs at 1600 cm -1 , the absorption peaks at 580 and 460 cm-1 are assigned to the stretching vibration peaks of the europium complexes N→Eu and ...

Embodiment 2

[0048] Accurately weigh 0.2425g PVB, 0.0075g Eu(TTA) 2 Tpy-OCH 3 , Dissolve Eu(TTA) with an appropriate amount of DMF (N-N-dimethylformamide) 2 Tpy-OCH 3 , Pour the dissolved solution into a beaker, then add 20ml of absolute ethanol and 30ml of THF to make a 5g / L solution. Drop an appropriate amount of the solution into a watch glass with a dropper, and let the solvent evaporate naturally at room temperature to prepare the complex Eu(TTA) 2 Tpy-OCH 3 The mass is 5% PVB red light film.

Embodiment 3

[0050] Accurately weigh 0.465g PVB, 0.035g Eu(TTA) 2 Tpy-OCH 3 , Dissolve Eu(TTA) with an appropriate amount of DMF (N-N-dimethylformamide) 2 Tpy-OCH 3 , Pour the dissolved solution into a beaker, then add 20ml of absolute ethanol and 30ml of THF to make a 10g / L solution. Drop an appropriate amount of the solution into a watch glass with a dropper, and let the solvent evaporate naturally at room temperature to prepare the complex Eu(TTA) 2 Tpy-OCH 3 PVB red light film with a mass of 7%.

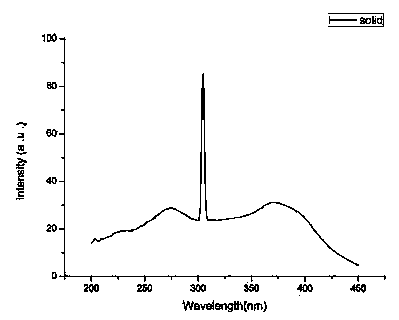

[0051] It can be clearly seen from the fluorescence test spectrum of the film that the characteristic emission peak of europium ions after doping is still at 617nm. And it can be seen that the luminous intensity of simple europium complexes is not high when dispersed in PVB film, and within the scope of experimental research, it increases with the increase of the content of europium complexes, and does not appear to increase with the increase of the content of europium complexes. Conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com