Method and device for improving concentration stability of calcium chloride solution used for sintering ore

A calcium chloride solution, stability technology, applied in the field of metallurgical industry, can solve the problems of not meeting the spraying process requirements, reducing the stability of calcium chloride solution, increasing the amount of spraying, etc., to ensure stable and economical production , Conducive to continuous production, reduce the effect of low temperature pulverization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

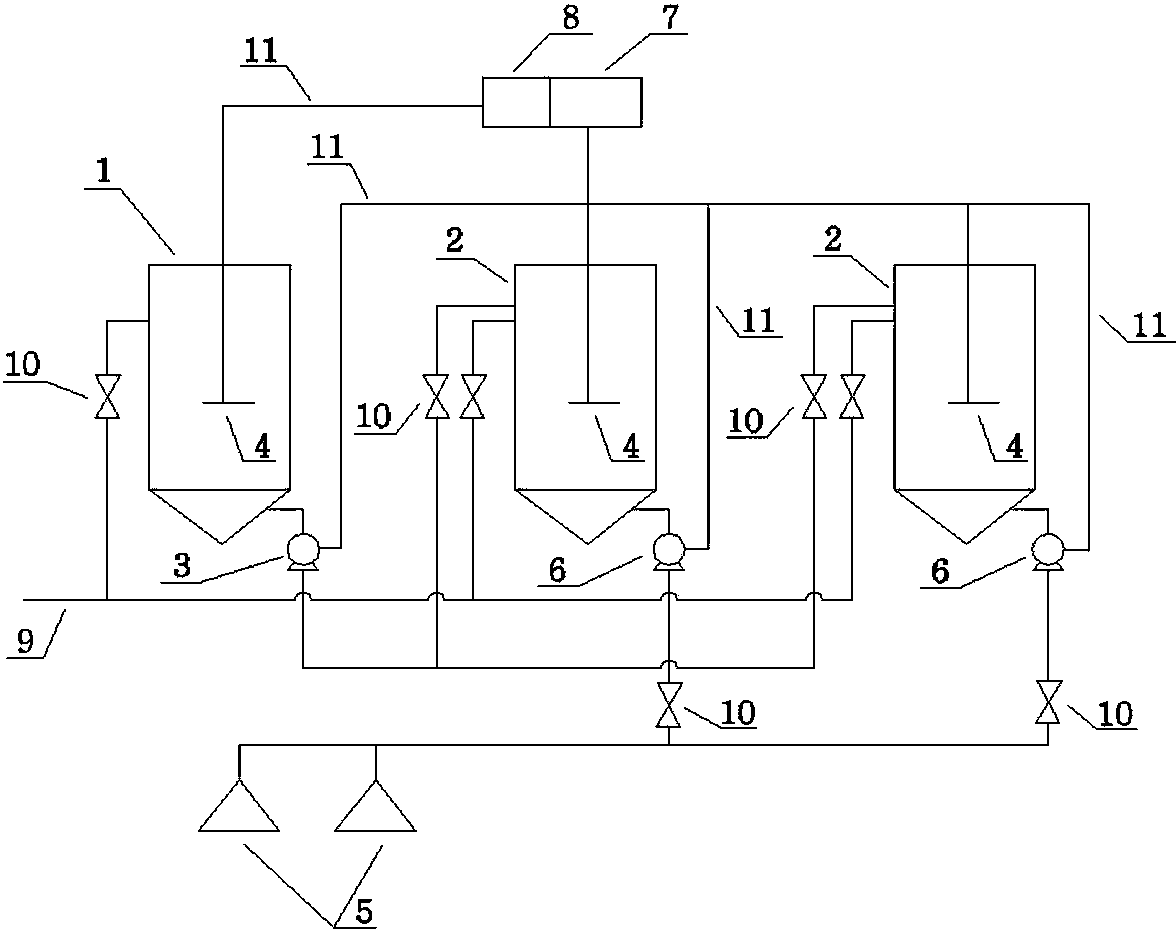

[0024] Kunming Iron and Steel Sintering Plant is equipped with calcium chloride spraying facilities on the feeding process line after the third and fourth sintered sinter finished product warehouses, and correspondingly set up a mother liquor storage pool and two solution pools, each pool has a volume of 13.5m3, The mother liquor pool stores calcium chloride mother liquor with a concentration > 30%. According to the current production status, one pool of mother liquor can be used for three days, and one pool of solution can be used for eight hours. The mother liquid pool is respectively connected with the solution pool through the submerged pump, and the spraying facilities are respectively connected with the solution pool through the submerged pump, and stirring pumps are respectively arranged in the middle of the mother liquid pool and the solution pool. Combine the control system of the mixing pump in the solution pool with the control system of the submerged pump, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com