Temporary steel trestle constructing method and trestle

A construction method, steel trestle technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve problems such as unfavorable project turnover, fire, poor corrosion resistance, etc., achieve good promotion prospects, good fire resistance, good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

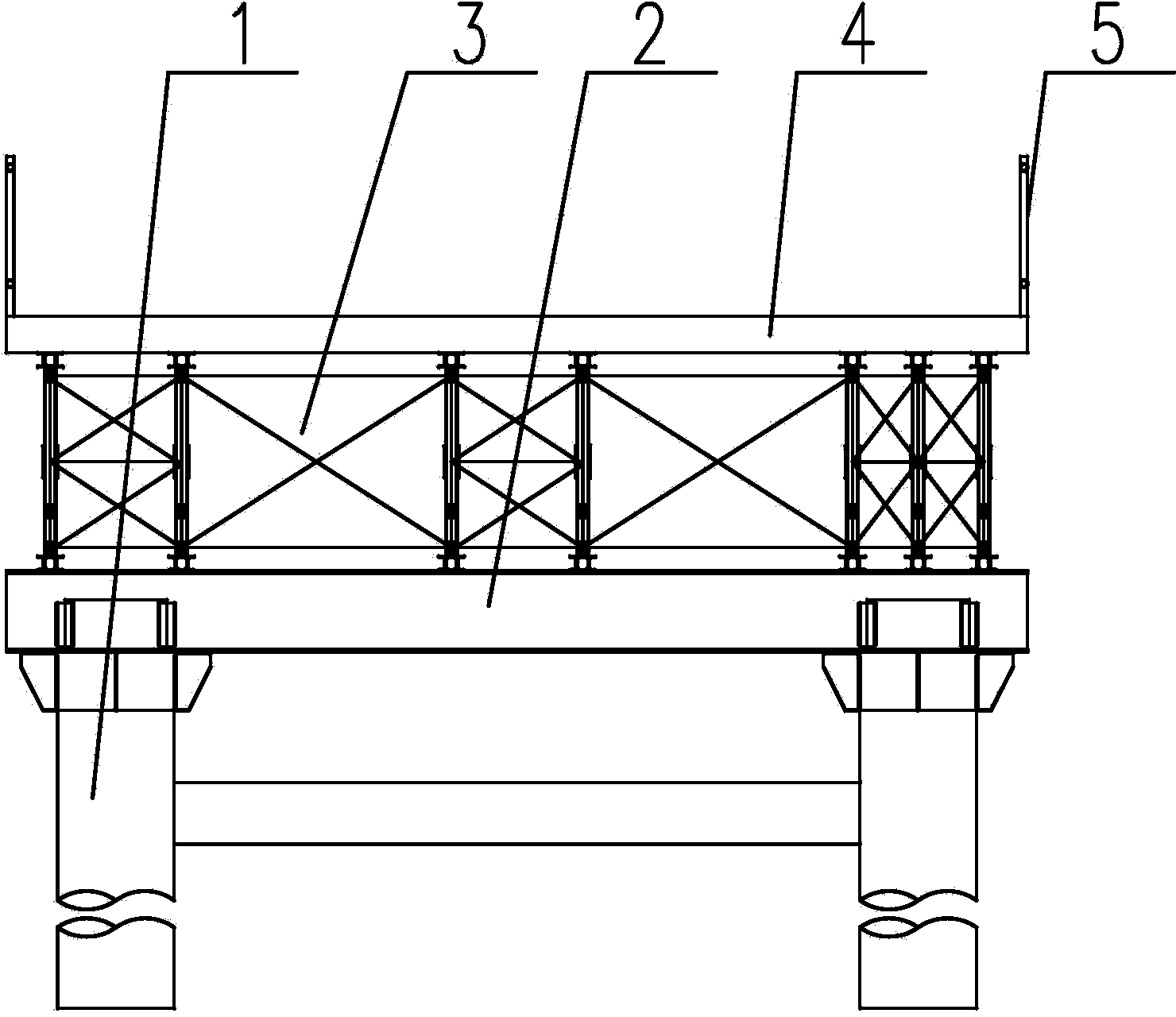

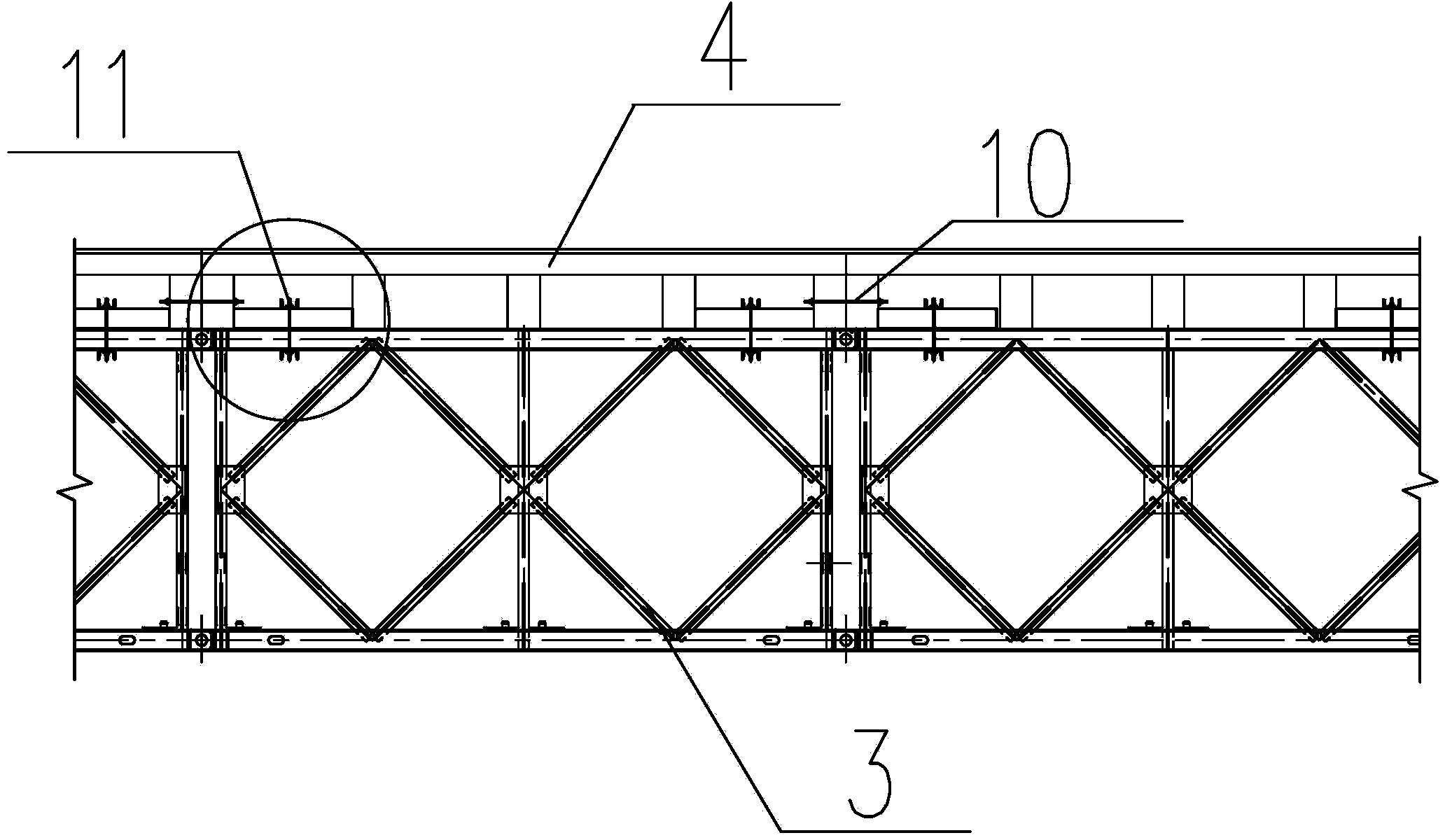

[0037] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0038] A construction method for a temporary steel trestle bridge, comprising the following steps in sequence:

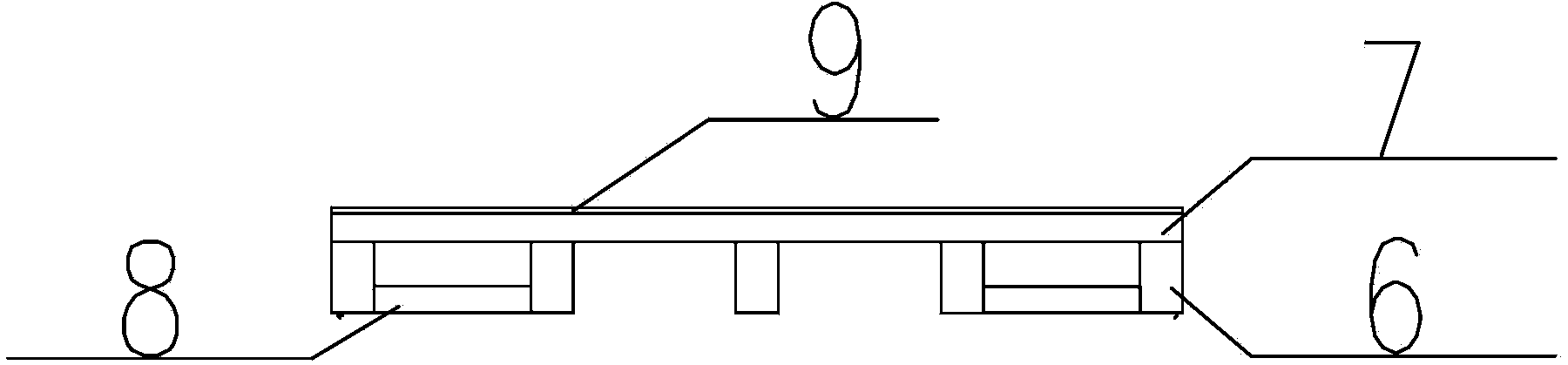

[0039] 1) Prefabrication of standard components: several standard parts of wood-plastic main beam 6, wood-plastic secondary beam 7, wood-plastic card beam 8 and wood-plastic panel 9 are prepared in advance;

[0040] 2) Prefabrication of wood-plastic bridge deck standard parts: the aforementioned prefabricated standard components are bonded into several wood-plastic bridge deck 41 standard parts, and each wood-plastic bridge deck 41 is composed of several wood-plastic main girders 6 and several wood-plastic bridge decks. The secondary beam 7, several wood-plastic card beams 8, and several wood-plastic panels 9 are bonded together; in each wood-plastic bridge deck 41, 6 wood-plastic main beams and 7 wood-plastic secondary beams are paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com