Combustion method and device for preventing high-sodium coal from coking and contamination

A combustion device and a technology of combustion and coking, applied in the combustion method, the fuel burned in the molten state, the combustion type, etc., can solve the problem of contamination that cannot be fundamentally solved, reduce coal combustion efficiency and boiler output, and affect coal combustion and combustion. In order to reduce process and material costs, improve penetration, and promote combustion and burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

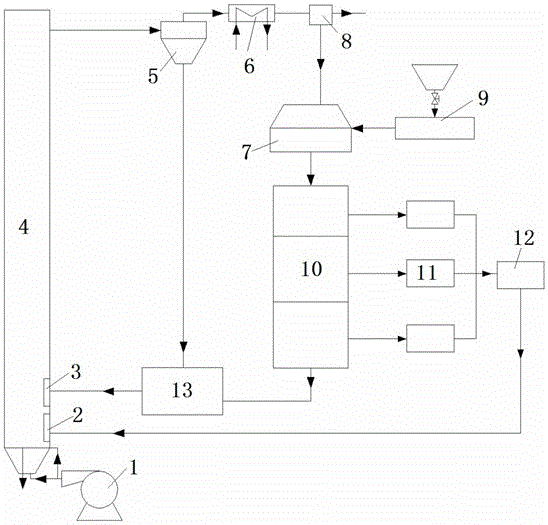

[0014] Such as figure 1 As shown, the combustion device for preventing high-sodium coal from coking and fouling of the present invention is composed of a circulating fluidized bed combustion system, a thermal desodiumization system and a fly ash circulation system.

[0015] The circulating fluidized bed combustion system includes: fluidized bed 4, cyclone separator 5, coke treatment device 13, swirl burner 3, gas burner 2 and blower 1;

[0016] The pyrolysis sodium removal system includes: a three-stage pyrolysis bed 10, a primary pyrolysis gas desodium purification device 11 and a secondary pyrolysis gas desodium purification device 12;

[0017] The fly ash circulation system includes: heat exchanger 6, dust collector 8, coal mill 7 and coal feeding system 9;

[0018] The connection relationship of the above components is as follows:

[0019] The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com