Visible-light-induced photocatalyst loaded with vanadium tetrasulfide and preparation method

A technology of vanadium tetrasulfide and catalyst is applied in the field of photocatalysis to achieve the effect of improving quantum efficiency and promoting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Visible light catalytic degradation of waste water containing formaldehyde

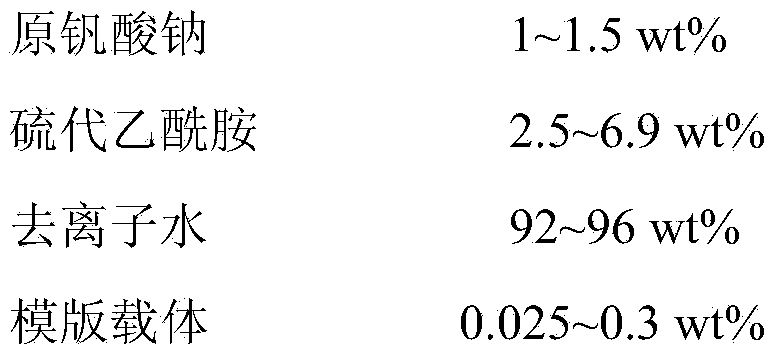

[0016] Prepare the catalyst as follows:

[0017] 1) Weigh 0.1343g of carbon nanotubes (CNTs), disperse them in 90mL of deionized water, and sonicate for 0.5h to form a homogeneous solution, ready for use;

[0018] 2) Weigh 2.7g sodium orthovanadate dodecahydrate and 7.5g thioacetamide (CH 3 CSNH 2 ), dissolved in the solution obtained in 1), and continuously stirred for 0.5h; transferred to a 150mL high-temperature hydrothermal reaction kettle, kept at 150°C for 12h, and cooled naturally to room temperature.

[0019] 3) The obtained product was centrifuged, washed with water and ethanol for 3 to 5 times, dried in vacuum at 60° C. for 6 hours, and ground to obtain VS containing 5% carbon nanotubes. 4 catalyst.

[0020] Prepare 500mL simulated industrial wastewater containing 1% formaldehyde solution, add 0.5g of the above catalyst, simulate sunlight with a 500W high-pressure xenon...

Embodiment 2

[0023] Example 2: Visible light catalytic decomposition of water to produce hydrogen

[0024] Prepare the catalyst as follows:

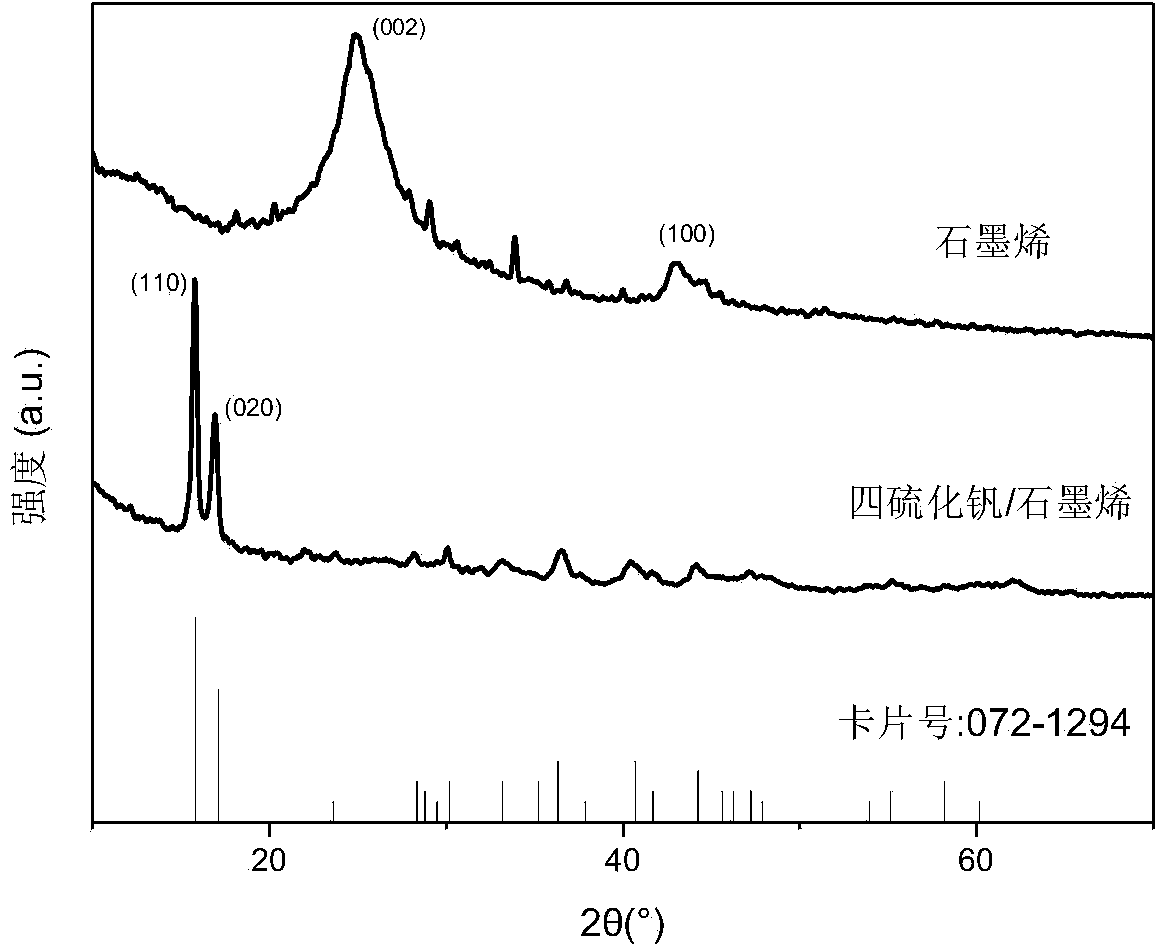

[0025] 1) Weigh 0.0537g graphene oxide (GO), disperse it in 60mL deionized water, and ultrasonicate for 1h to form a homogeneous solution, ready for use;

[0026] 2) Weigh 1.8g Na 3 VO 4 12H 2 O and 1.65g CH 3 CSNH 2 , dissolved in the solution obtained in 1), and kept stirring for 1 hour; transferred to a 100mL high-temperature hydrothermal reaction kettle, kept at 160°C for 24 hours, and cooled naturally to room temperature.

[0027] 3) The obtained product was centrifuged, washed with water and ethanol for 3 to 5 times, dried in vacuum at 60°C for 6 hours, and ground to obtain VS containing 3% graphene. 4 catalyst.

[0028] Configuration with NaS 2 Concentration 0.35mol / L, Na 2 SO 3 Add 0.5g catalyst to 500mL of 0.25mol / L solution, avoid light and sonicate for 0.5h, simulate sunlight with 500W high-pressure xenon lamp (filter wavelength ...

Embodiment 3

[0029] Example 3: Visible light catalytic decomposition of biomass ethanol to produce hydrogen

[0030] Prepare the catalyst as follows:

[0031] 1) Weigh 0.0537g of ground silver sulfide powder, disperse it in 60mL of deionized water, and ultrasonicate for 0.5h to form a homogeneous solution, ready for use;

[0032] 2) Weigh 1.8g Na 3 VO 4 12H 2 O and 1.65g CH 3 CSNH 2 , dissolved in the solution obtained in 1), and continuously stirred for 1.5h; transferred to a 100mL high-temperature hydrothermal reaction kettle, kept at 160°C for 48h, and cooled naturally to room temperature.

[0033] 3) The obtained product was centrifuged, washed with water and ethanol for 3 to 5 times, then vacuum-dried at 60°C for 6 hours, and ground to obtain 3% Ag 2 S VS 4 catalyst of light.

[0034] In a 500mL photocatalytic reactor, add 0.5g catalyst, 500mL biomass ethanol, add 0.1mol Na 2 Mix S well, avoid light and ultrasonically for 0.5h, use 500W high-pressure xenon lamp (filter wavele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com