Sulfur autotrophic denitrification granule sludge as well as preparation method and application thereof

A nitrifying particle and sulfur autotrophic technology, applied in anaerobic digestion treatment and other directions, can solve the problems of accumulation of intermediate products and difficult to solve, and achieve the effects of rapid growth, small equipment footprint, and low investment and operation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

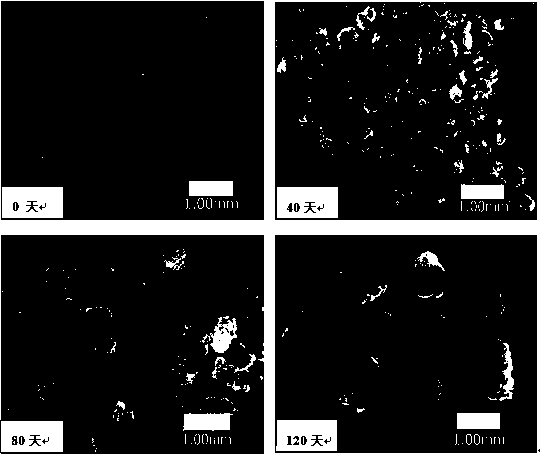

[0021] Embodiment 1, the cultivation of a kind of sulfur autotrophic denitrification granular sludge

[0022] The upflow anoxic sludge reactor was initially inoculated with fresh flocculent sludge from the secondary sedimentation tank of domestic sewage treatment plant and autotrophic denitrification sludge that was statically cultured for 2 months. At the beginning of the experiment, the concentration of nitrate in the influent water was maintained at 70 mg / L (calculated as N), and the functional strains of sulfur autotrophic denitrification were quickly screened out with a higher concentration of sulfide (140 mg / L, measured as S). At the same time, a certain amount of trace element nutrient solution is added to the influent (separately, not mixed with the influent), but no organic carbon source is added, which is beneficial to the growth of autotrophic bacteria.

[0023] During the cultivation period, the rising flow rate of the reactor was gradually increased from 0.4 m / h t...

Embodiment 2

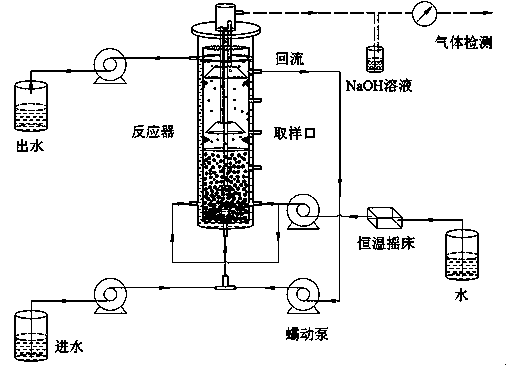

[0024] Example 2 The upflow anoxic sludge reactor wastewater treatment system shown in the attached figure is used to inoculate the flocculent sludge in the secondary sedimentation tank of domestic sewage plant to cultivate sulfur autotrophic denitrification granular sludge and treat artificial simulated wastewater.

[0025] The inner diameter of the upflow anoxic sludge reactor is 18.9 cm, the total height is 117.0 cm, the effective reaction height is 106.9 cm, the effective reaction volume of the reactor is 30 L, and the reaction temperature is controlled at 25-30 ℃ by the water circulation pipeline of the constant temperature shaker . Two three-phase separators are installed on the upper part of the reactor to separate gas, liquid and solid. In addition, a return line is set up, and the gas generated by the reaction is collected after passing through the alkaline absorption liquid.

[0026] Artificial waste water is used as influent, which mainly includes Na 2 S·9H 2 O, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com