Sludge biochemical treatment system and method

A biochemical sludge and treatment system technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low treatment cost, insignificant sludge reduction, and high ozone injection ratio , to achieve the effect of reducing the ammonia nitrogen index, reducing the amount of sludge transported abroad, and enhancing the settling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

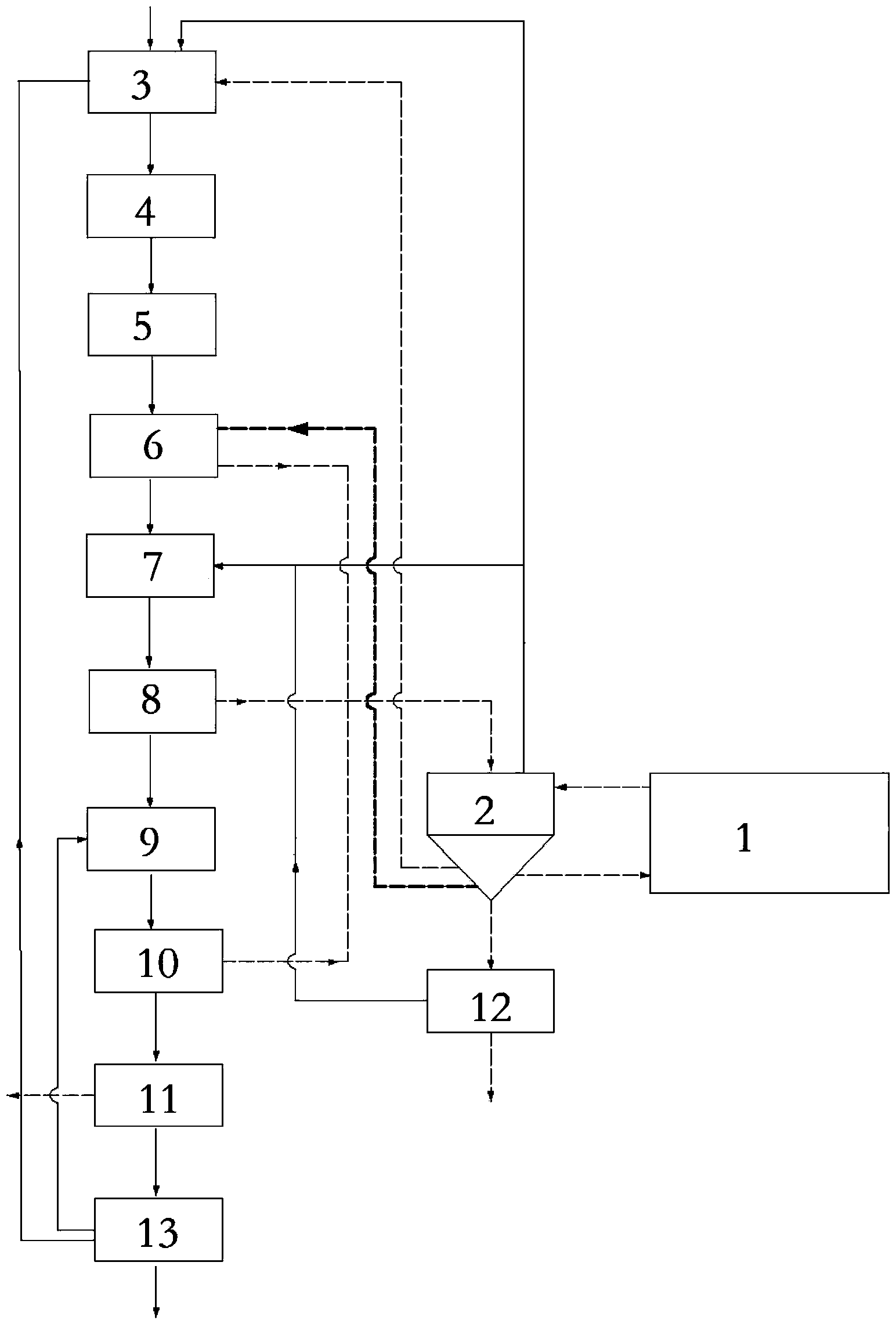

[0030] Such as figure 1 As shown, the dotted line is the mud line, and the solid line is the water line. A biochemical sludge treatment system of the present invention, the biochemical sludge treatment system includes a sludge treatment device 1, a sludge concentration tank 2, a homogeneous adjustment tank 3, a neutralization tank 4, a primary sedimentation tank 5, an anaerobic tank 6, Primary aerobic tank 7, secondary sedimentation tank 8, secondary aerobic tank 9, final sedimentation tank 10, air flotation tank 11, filter press 12 and monitoring tank 13;

[0031] The sludge thickening tank 2, homogeneous adjustment tank 3, neutralization tank 4, primary sedimentation tank 5, anaerobic tank 6, primary aerobic tank 7, secondary sedimentation tank 8, secondary aerobic tank 9, final sedimentation tank The pool 10, the air flotation pool 11 and the monitoring pool 13 are connected successively; the filter press 12 is connected with the primary aerobic pool 7;

[0032] The sludg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com