Method for synthesizing icatibant

A peptide resin and coupling technology, which is applied in the field of synthesizing icatibant, can solve the problems of peptide chain shedding, high impurity content, and low application value, so as to improve the yield, optimize the synthesis process, and improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

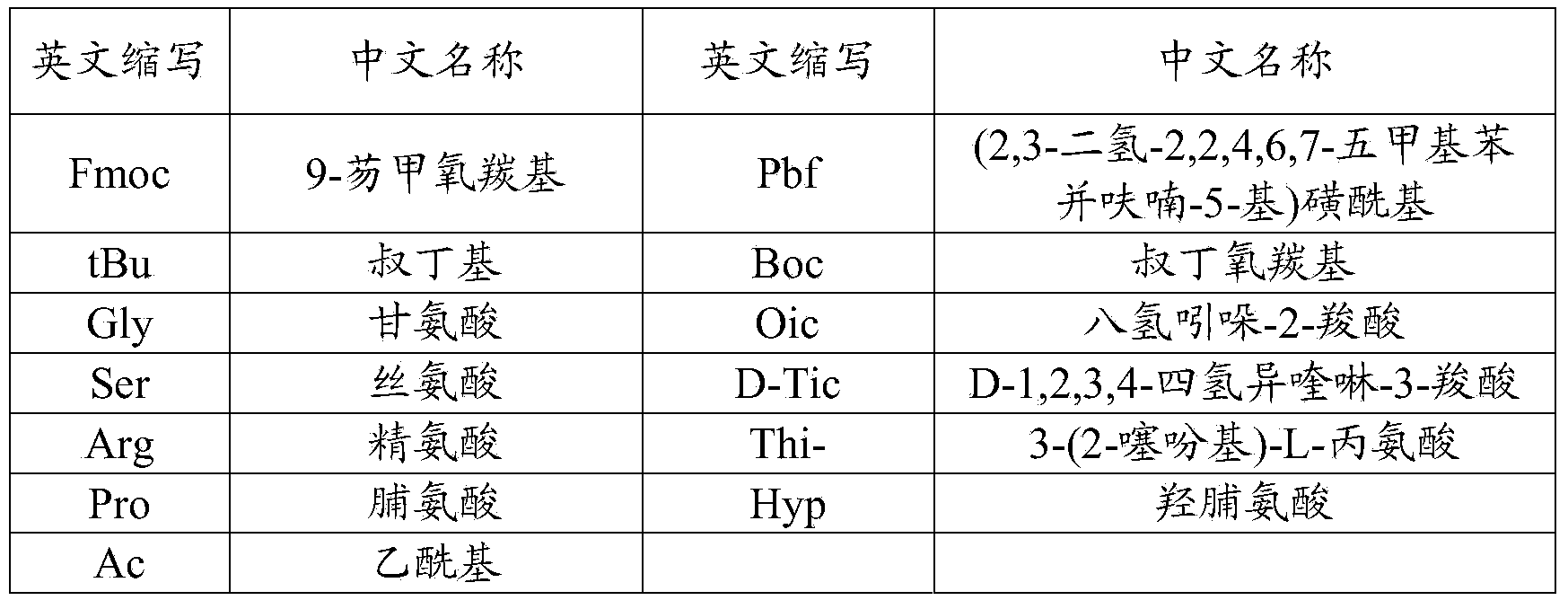

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Synthesis of Peptide Resin 1

[0042] 100 g of Wang resin with a substitution degree of 0.80 mmol / g was added to a solid-phase reaction column, and DMF was added to swell the resin for 30 minutes and then drained. Take 155.6g Fmoc-Arg(Pbf)-OH and 32.5g HOBt, dissolve them in DMF, add them to the above resin, stir well, then add 33mL DIC and 3.0g DMAP, stir and react at room temperature for 6 hours, remove the reaction liquid, wash with DMF After 3 times, DCM was washed 3 times, methanol was washed 3 times, each washing time was 3min, and Fmoc-Arg(Pbf)-Wang resin was obtained, and the detection substitution degree was 0.51mmol / g.

Embodiment 2

[0043] Example 2: Synthesis of Peptide Resin 1

[0044] Add 100 g of HMP resin with a substitution degree of 0.75 mmol / g into the solid-phase reaction column, add DMF to swell the resin for 30 minutes, and drain it. Take 145.8g Fmoc-Arg(Pbf)-OH and 30.4g HOBt, dissolve them in DMF, add them to the above resin, stir well, then add 30.5mL DIC and 2.8g DMAP, stir at room temperature for 6 hours, remove the reaction solution, DMF After washing 3 times, DCM washed 3 times, methanol washed 3 times, each washing time was 3min, and Fmoc-Arg(Pbf)-Wang resin was obtained, and the detection substitution degree was 0.49mmol / g.

Embodiment 3

[0045] Example 3: Synthesis of Peptide Resin 2 (Coupling of Fmoc-Oic-OH)

[0046] Take 0.1mol Fmoc-Oic-OH and 0.1mol HOBt, and dissolve them with an appropriate amount of DMF; take another 0.1mol DIC, slowly add it under stirring, stir and react at room temperature for 30 minutes, and obtain the activated amino acid solution for later use;

[0047] Take 0.05mol of the Fmoc-Arg(pbf)-Wang resin of Example 1 (i.e. peptide resin 1, the substitution value is about 0.51mmol / g peptide resin 1), deprotect it with 1000mL 20% PIP / DMF solution for 25 minutes, wash and filter to obtain De-Fmoc Peptide Resin 1;

[0048] The activated amino acid solution is added to the peptide resin 1 without Fmoc, the coupling reaction is 60-300 minutes, the reaction end point is determined by the ninhydrin method, and the peptide resin 2 is obtained by filtering and washing, Fmoc-Oic-Arg (pbf )-Wang Resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com