Preparation method for full saccharose polyether polyol

A technology of polyether polyol and sucrose, which is applied in the field of preparation of full sucrose polyether polyol, can solve the problems of long reaction cycle, unstable index, poor effect, etc., and achieve low cost, sufficient reaction, and good index stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

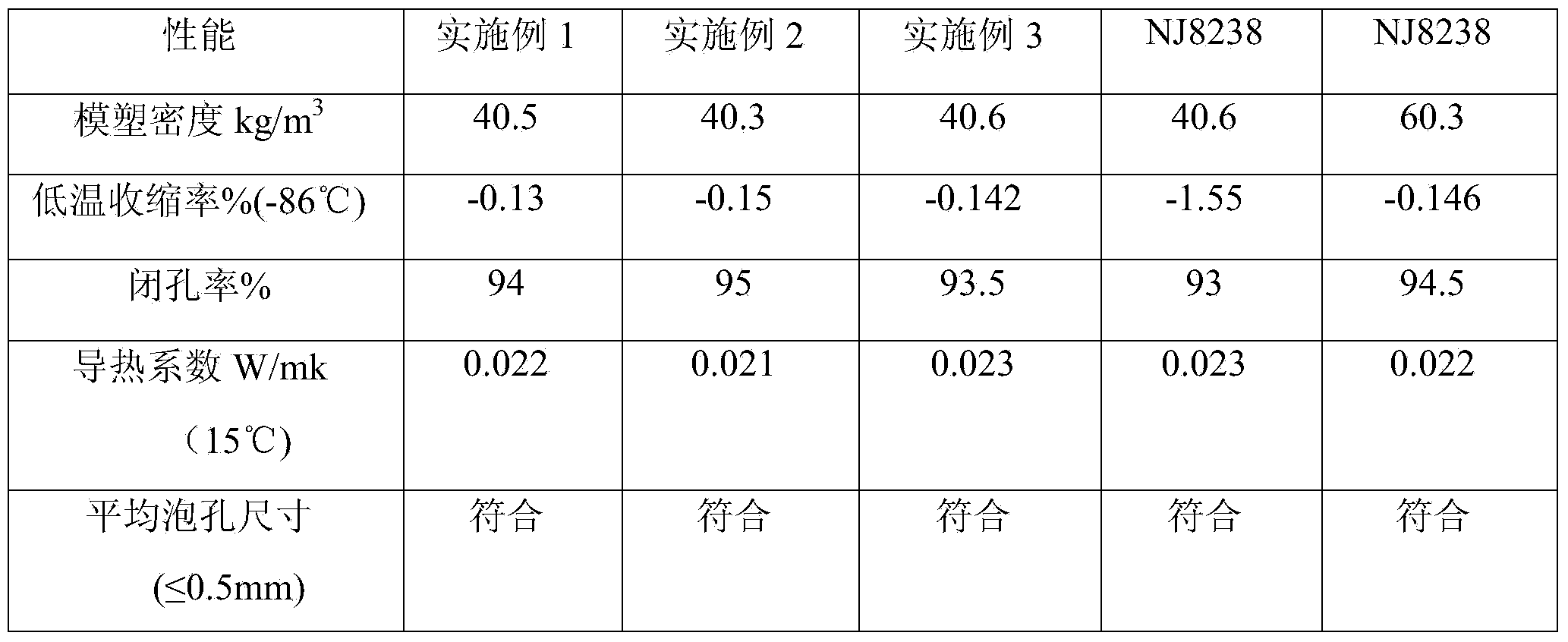

Examples

Embodiment 1

[0023] In a 5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 342g of sucrose, 3.74g of catalyst KOH, and 37.4g of DMI (KOH and DMI Mixed into a solution), replaced with nitrogen 5 times, and vacuumed to a pressure of -0.08MPa, then stirred (500 rpm) to heat up, when the temperature increased to 85°C, 75g of propylene oxide was added, and the reaction temperature was controlled at 85±3°C , the initial pressure is 0.25±0.02Mpa, react until the pressure is constant, then raise the temperature to 95°C and vacuum aging for 3h. Afterwards, the temperature was controlled at 130°C, the pressure was controlled at 0.25MPa, and the remaining 830g of propylene oxide was divided into 10 batches and added successively, and the aging was continued for 1 hour after reacting until the pressure stopped changing. Finally, add 8g of phosphoric acid and 37.5g of water at 95...

Embodiment 2

[0031] In a 5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 342g of sucrose, 3.74g of catalyst KOH, and 62.33g of DMI (KOH and DMI Mixed into a solution), replaced with nitrogen 5 times, and vacuumed to a pressure of -0.08MPa, then stirred (500 rpm) to heat up, when the temperature increased to 85°C, 75g of propylene oxide was added, and the reaction temperature was controlled at 85±3°C , the initial pressure is 0.25±0.02Mpa, react until the pressure is constant, then raise the temperature to 105°C and vacuum aging for 4h. Afterwards, the temperature was controlled at 100°C and the pressure was controlled at 0.25MPa. The remaining 830g of propylene oxide was divided into 10 batches and added successively, and the reaction was continued until the pressure did not change, and then aging was continued for 1h. Finally, add 8g of phosphoric acid and 37.5g o...

Embodiment 3

[0039] In a 5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 342g of sucrose, 3.74g of catalyst KOH, and 112.2g of DMI (KOH and DMI Mixed into a solution), replaced with nitrogen 5 times, and vacuumed to a pressure of -0.08MPa, then stirred (500 rpm) to heat up, when the temperature increased to 85°C, 75g of propylene oxide was added, and the reaction temperature was controlled at 85±3°C , the initial pressure is 0.25±0.02Mpa, react until the pressure is constant, then raise the temperature to 115°C and vacuum aging for 5h. Afterwards, the temperature was controlled at 110°C and the pressure was controlled at 0.30 MPa, and the remaining 830 g of propylene oxide was divided into 10 batches and added successively, and the reaction was continued until the pressure did not change, and then aging was continued for 1 h. Finally, add 8g of phosphoric acid and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com