A kind of lignite additive and lignite dehydration treatment method

A treatment method and additive technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of unfavorable industrial utilization of lignite and changes in the properties of lignite, and achieve the effects of high production efficiency, reduced dielectric loss, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with specific embodiments.

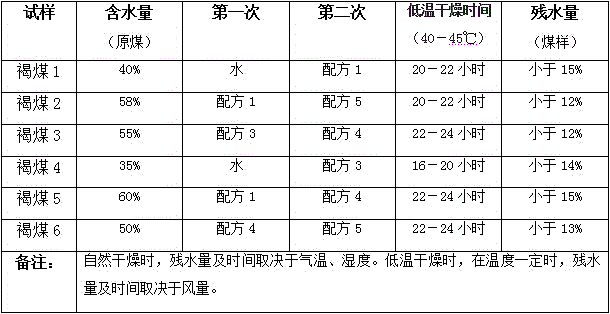

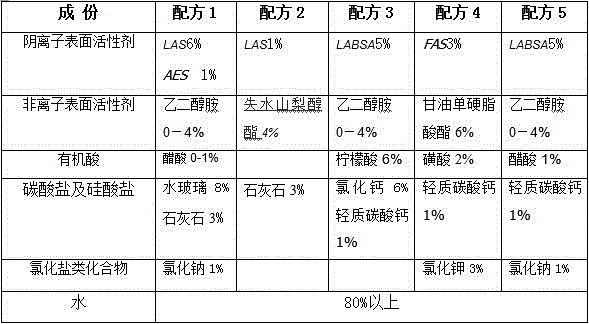

[0029] (1) The present invention provides a lignite dehydration additive, which is prepared by mixing water with at least three of ionic surfactants, nonionic surfactants, organic acids, water glass, carbonates and chlorides in proportion , wherein the proportion of water is more than 80%. Specific examples are as follows:

[0030]

[0031] The aqueous lignite dehydration additive provided by the invention is analyzed and selected according to the characteristics of lignite.

[0032] 1. The aqueous solution additive is composed of several materials such as ionic surfactant, non-ionic surfactant, organic acid, water glass, carbonate and other salt compounds, according to the different characteristics of raw material lignite and the order of use of additives, According to different proportions (the above components increase or decrease within the range of 0-10%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com