Anti-bacterial clothing softening agent

A technology of fabric softener and viscosity reducing agent, applied in the direction of animal fiber, biochemical fiber treatment, textile and papermaking, etc., can solve the problems of corrosion, poor soft and fluffy effect, skin damage, etc., and achieve comfortable hand feeling, good antibacterial and bacteriostatic effect. effect, the effect of soft clothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Take each raw material according to the ratio of raw materials in Table 1;

[0060]Take deionized water, heat up to 70-72°C, add bis fatty acid ethyl ester hydroxyethyl methyl ammonium methyl sulfate, stir until dissolved; add viscosity reducer, stir until the viscosity decreases; cool, and the temperature drops to 40 At ~50°C, add almond oil amidopropylamine oxide, double polyethylene polydimethylsiloxane, methyl-1-tallow amidoethyl-2-tallow imidazoline methyl sulfate, stir, Make it dissolve; add triclosan and marine actinomycetes to mix, adjust the pH value to 3-5; filter through a 200-300 mesh filter and pack.

[0061] Table 1 Fabric Softener Formula Unit: Kilogram

[0062] raw material example 1 Example 2 Example 3 Example 4 Example 5 Difatty Acid Ethyl Hydroxyethyl Ammonium Methyl Sulfate 8 20 14 11 15.5 Viscosity reducer 0.2 1 0.7 0.4 0.8 Almond Oleamidopropylamine Oxide 0.1 0.45 0.16 0.12 0.2 Double Polyethyl...

Embodiment 2

[0064] On the basis of the examples, add 0.2 kg of microcapsule essence to the prepared fabric softener, stir and mix evenly.

Embodiment 3

[0066] The fabric softener prepared by the present invention is tested according to national standards and industry standards such as "Test of Antistatic Performance of Fabric Conditioner" (GB / T 16801-1997).

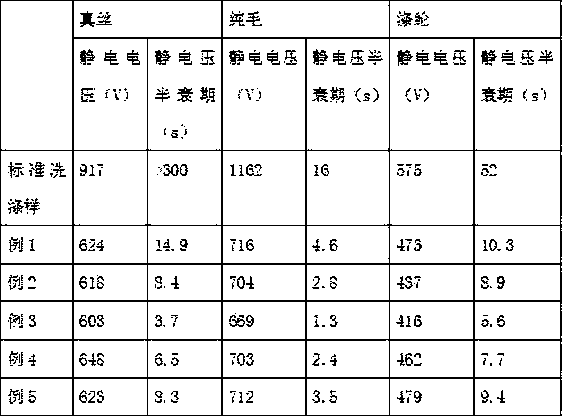

[0067] 1. Antistatic performance test

[0068]

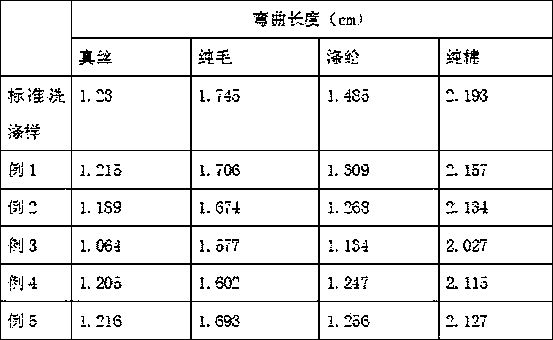

[0069] 2. Bending soft performance test

[0070]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com