Water for emulsifying oil, method for producing water for emulsifying oil, and method and apparatus for emulsifying oil

A manufacturing method and a technology for a manufacturing device are applied in the fields of water for emulsifying oil, water for emulsifying oil, emulsifying oil and devices, which can solve the problem of high cost and achieve the effect of easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

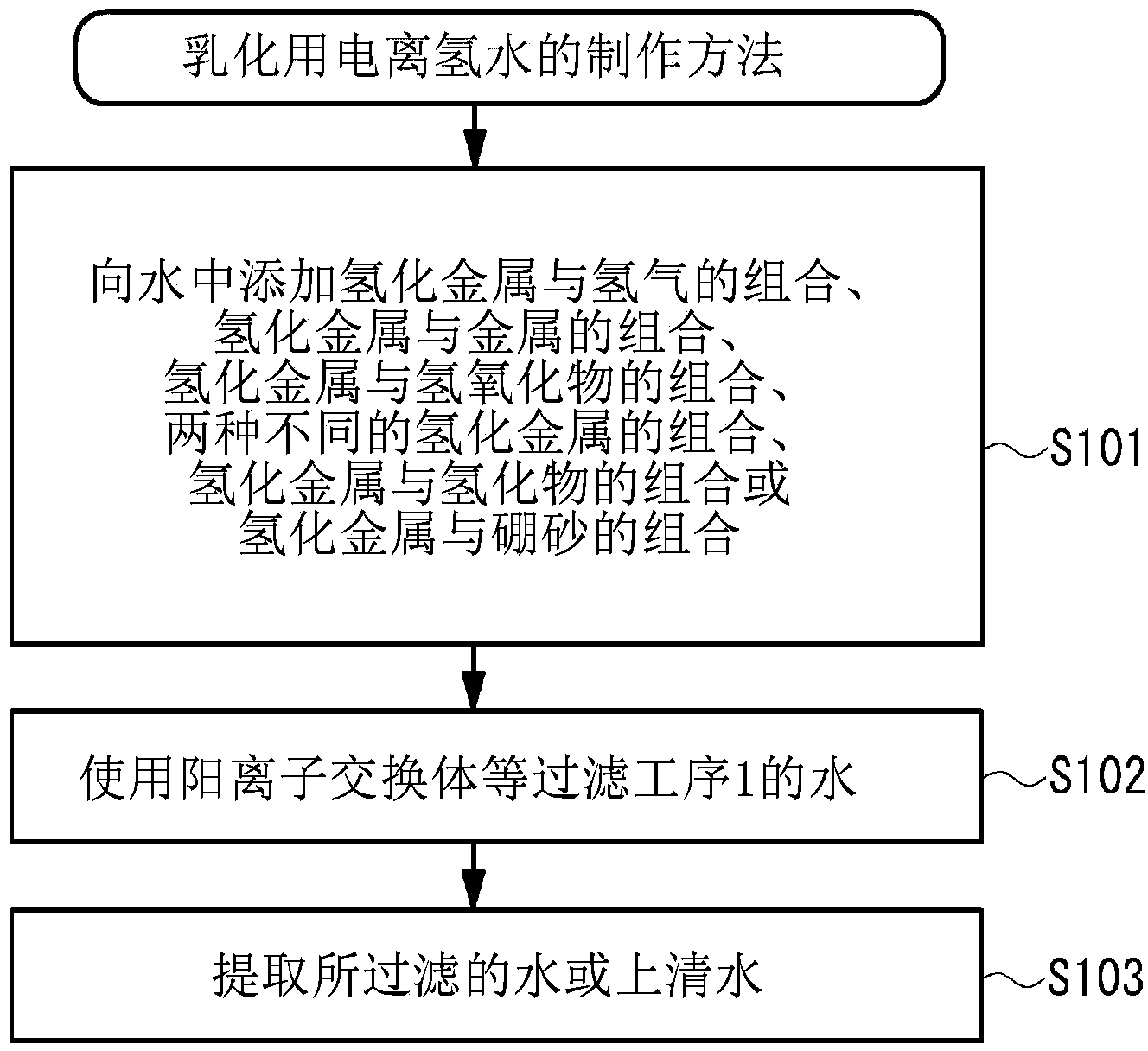

[0064] Figure 1A It is a figure explaining the preparation method of the water which emulsifies oil (henceforth referred to as ionized hydrogen water for emulsification) of the Example of this invention. Here, the oil to be emulsified is not particularly limited, and the oil includes heavy oil, light oil, vegetable oil (such as chili oil, rice bran oil, salad oil, olive oil, neem oil, perilla oil, linseed oil, grape seed oil, etc. oil, sesame oil, etc.), animal fats (such as tallow), fish oil, etc.

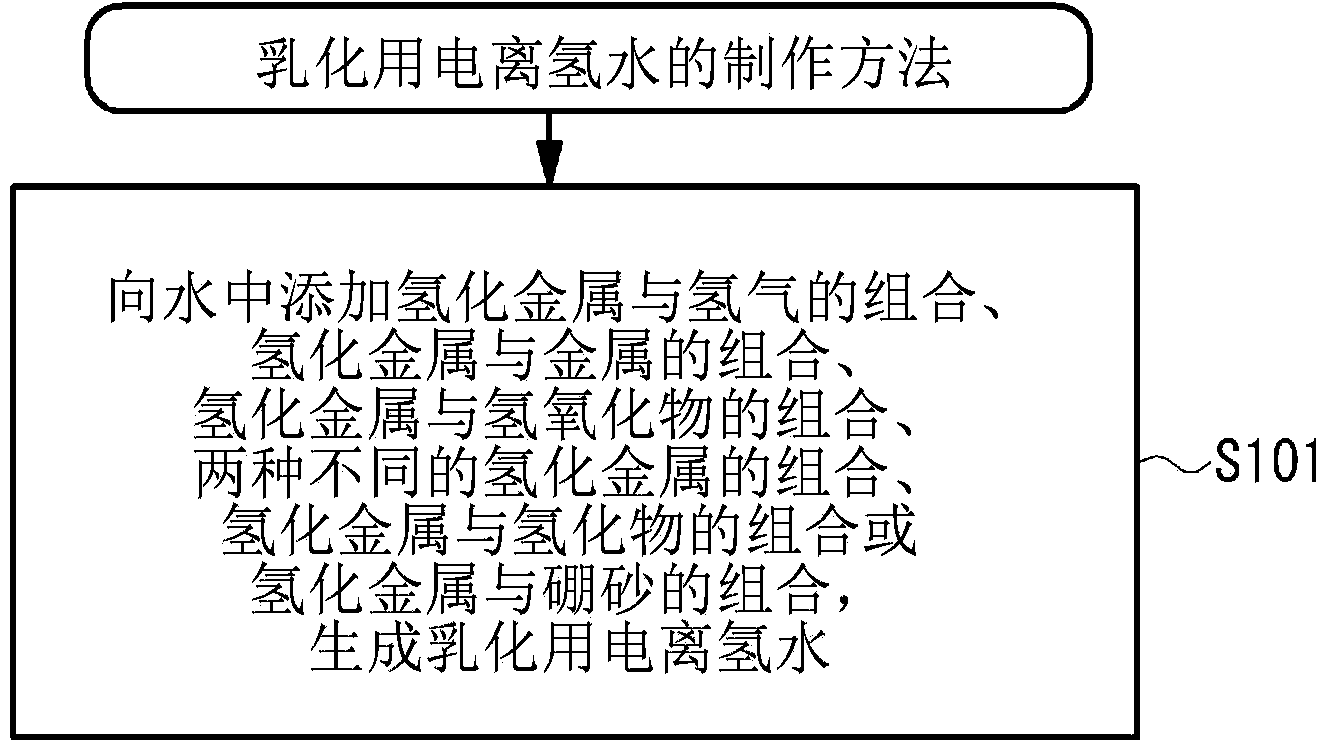

[0065] First, if Figure 1A Shown in step S101, prepare water (such as ultrapure water, tap water, natural water), add hydrogenation metal etc. to this water, generate ionized hydrogen water or negative hydrogen ion water that negative hydrogen ion is in plasma state at normal temperature. In particular, when emulsifying heavy oil, it is desirable to generate ionized hydrogen water from ultrapure water.

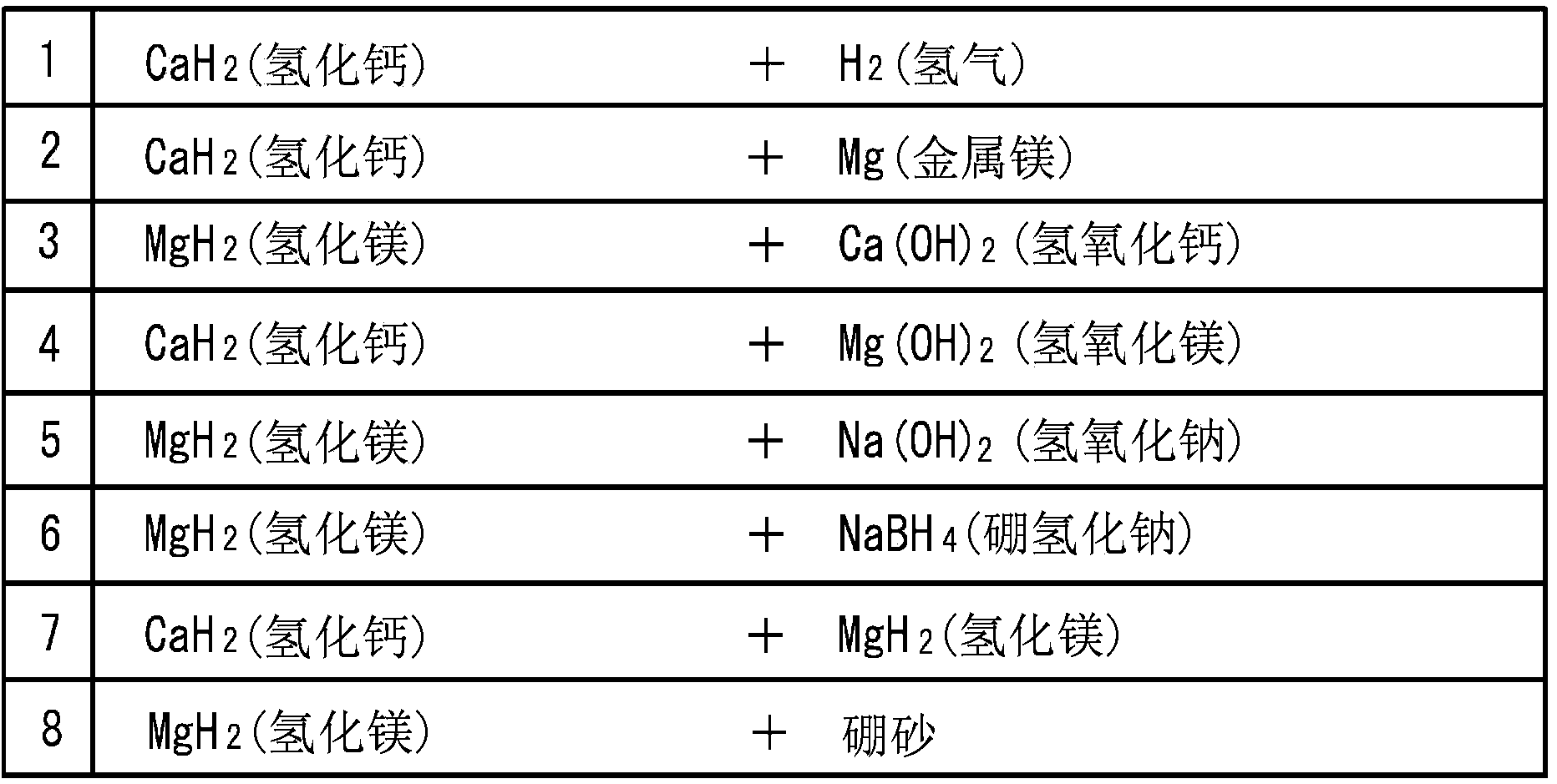

[0066] In the first preferred embodiment, metal hydride and hydrogen gas a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com