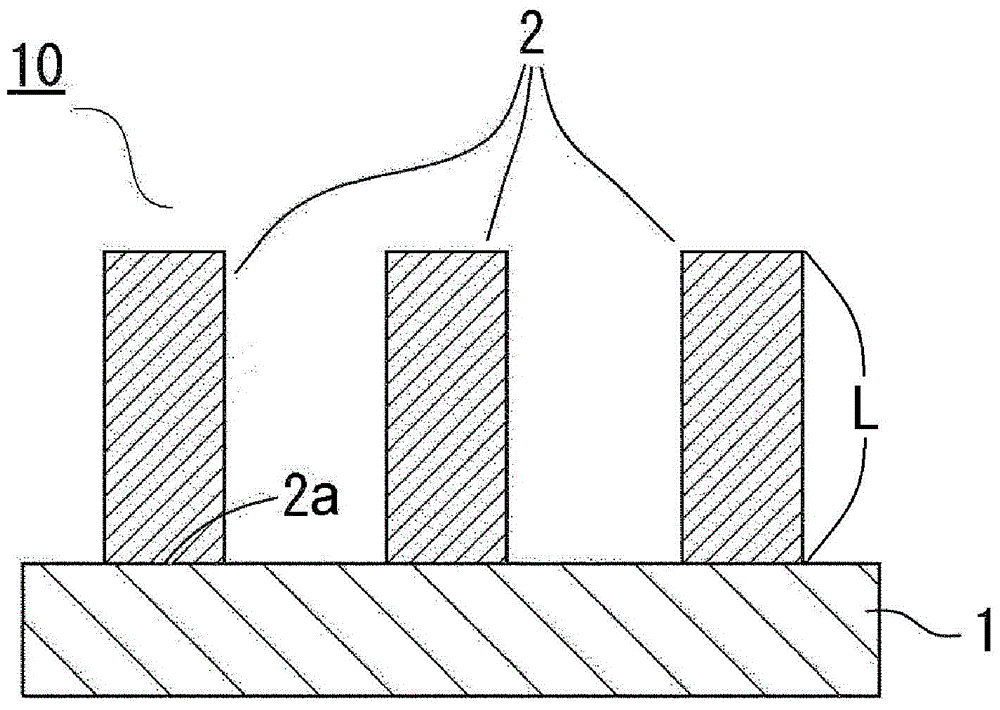

Sample fixing member for time-of-flight secondary ion mass spectrometer

A secondary ion mass spectrometer and analysis device technology, applied in the field of sample fixing parts, can solve the problems of inaccurate detection, hindering the generation of secondary ions, etc., and achieve the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

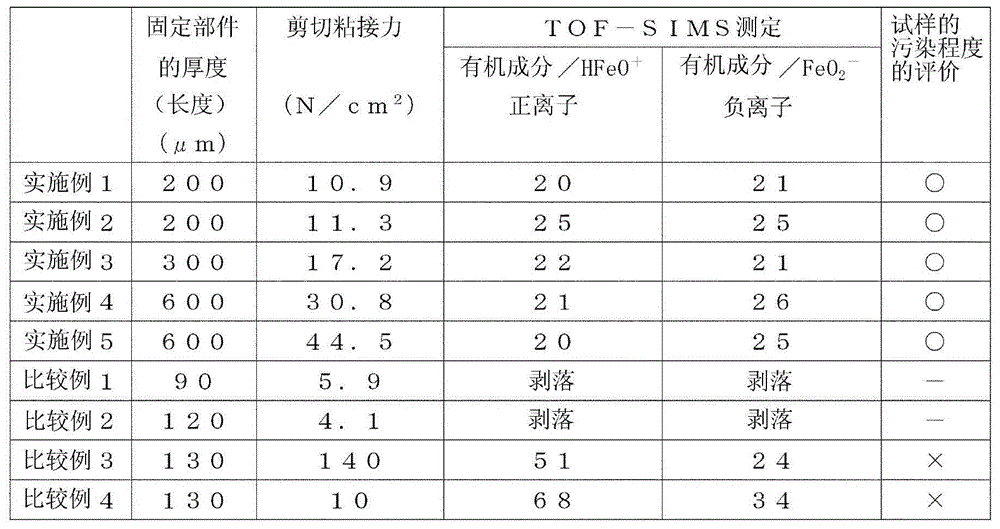

Examples

Embodiment 1

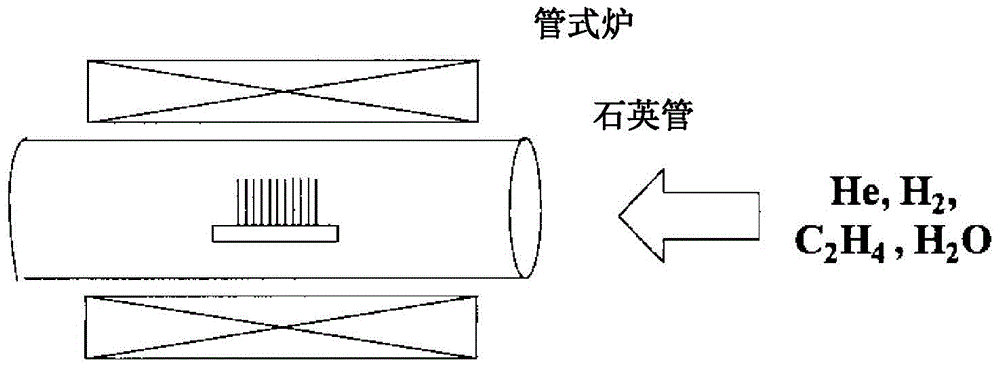

[0100] Form an Al thin film (thickness 10nm) on a silicon substrate (manufactured by KST, wafer with a thermally oxidized film, thickness 1000μm) using a vacuum evaporation device (manufactured by JEOL, JEE-4X Vacuum Evaporator), and then perform oxidation at 450°C for 1 hour deal with. In this way, Al is formed on the silicon substrate 2 o 3 membrane. in the Al 2 o 3 On the film, an Fe thin film (2 nm in thickness) was further vapor-deposited by a sputtering apparatus (manufactured by ULVAC, RFS-200) to form a catalyst layer.

[0101]Next, the obtained silicon substrate with the catalyst layer was cut and placed in a 30mmφ quartz tube, and a mixed gas of helium / hydrogen (120 / 80sccm) with a water content of 350ppm was flowed in the quartz tube for 30 minutes to replace the inside of the tube. Then, the temperature was raised to 765° C. within the tube stepwise over 35 minutes using an electric tube furnace, and then stabilized at 765° C. With the temperature kept at 765°...

Embodiment 2

[0106] An Al thin film (thickness: 10 nm) was formed on a silicon wafer (manufactured by Silicon Technology) as a substrate by a sputtering device (manufactured by ULVAC, RFS-200). Further, an Fe thin film (thickness: 1 nm) was vapor-deposited on this Al thin film using a sputtering device (manufactured by ULVAC, RFS-200).

[0107] Then, the substrate was placed in a 30 mmφ quartz tube, and a mixed gas of helium / hydrogen (90 / 50 sccm) with a water content of 600 ppm was flowed in the quartz tube for 30 minutes to replace the inside of the tube. Then, the temperature inside the tube was raised to 765°C using a tube electric furnace, and then stabilized at 765°C. With the temperature kept at 765°C, the mixed gas of helium / hydrogen / ethylene (85 / 50 / 5 sccm, moisture content 600ppm) was filled in the tube, and left for 10 minutes to allow the carbon nanotubes to grow on the substrate, and the carbon nanotubes were obtained according to Aggregates of carbon nanotubes oriented in the ...

Embodiment 3

[0112] Form an Al thin film (thickness 10nm) on a silicon substrate (manufactured by KST, wafer with a thermally oxidized film, thickness 1000μm) using a vacuum evaporation device (manufactured by JEOL, JEE-4X Vacuum Evaporator), and then perform oxidation at 450°C for 1 hour deal with. In this way, Al is formed on the silicon substrate 2 o 3 membrane. in the Al 2 o 3 Further, an Fe thin film (thickness: 2 nm) was vapor-deposited on the film using a sputtering device (manufactured by ULVAC, RFS-200) to form a catalyst layer.

[0113] Next, the obtained silicon substrate with the catalyst layer was cut and placed in a 30mmφ quartz tube, and a mixed gas of helium / hydrogen (120 / 80sccm) with a water content of 350ppm was flowed in the quartz tube for 30 minutes to replace the inside of the tube. Then, the temperature was raised to 765° C. within the tube stepwise over 35 minutes using an electric tube furnace, and then stabilized at 765° C. With the temperature kept at 765°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com