Method for regenerating zinc oxide desulfurization waste agent

A zinc oxide and desulfurizing agent technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high cost, unsuitable for industrial application, etc., reduce the regeneration cost, be beneficial to industrial production, and improve the reaction yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The regeneration method of zinc oxide desulfurization waste agent described in the present embodiment is:

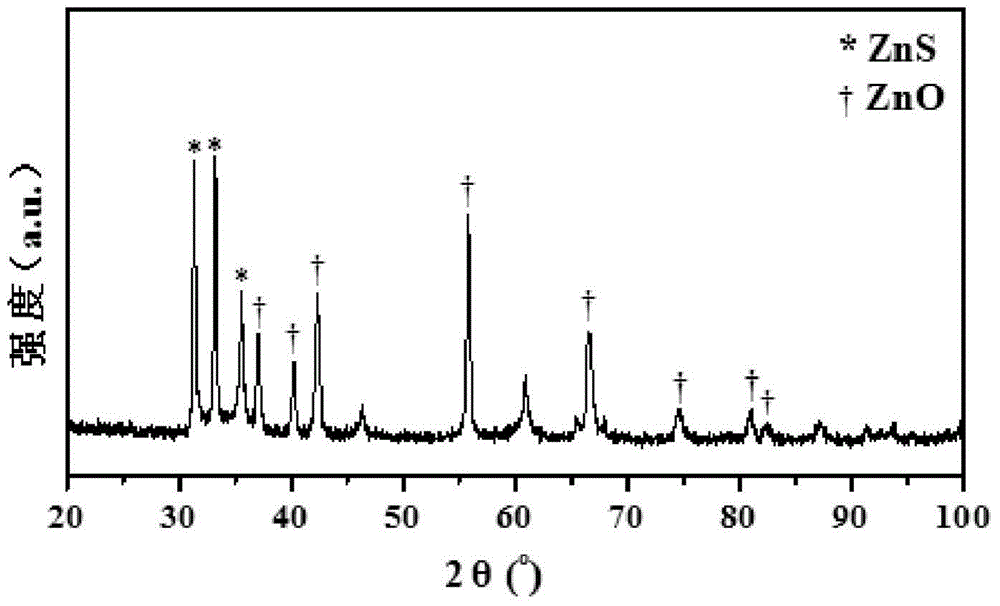

[0022] Add 1g of zinc oxide desulfurization waste agent and 70mL of deionized water to a 100mL hydrothermal reaction kettle in sequence, place the hydrothermal reaction kettle in an oven at 200°C for 24 hours, cool naturally after the reaction is completed, and filter the reaction solution. Collect the filter residue, wash the filter residue 6 times with deionized water, and dry at 110° C. for 10 hours to obtain a regenerated zinc oxide desulfurizer. Grind the regenerated zinc oxide desulfurizer into a powder of more than 200 meshes, and use X-ray diffractometer (XRD) to carry out structural characterization, such as figure 1 As shown, the diffraction peak changes of zinc oxide and zinc sulfide were observed.

Embodiment 2

[0024] The regeneration method of zinc oxide desulfurization waste agent described in the present embodiment is:

[0025] Add 1g of zinc oxide desulfurization waste agent, 60mL of deionization and 10mL of ammonia water to a 100mL hydrothermal reaction kettle in sequence, place the hydrothermal reaction kettle in an oven at 250°C for 12 hours, cool naturally after the reaction is completed, and dissolve the reaction solution filtering, collecting the filter residue, washing and drying the filter residue to obtain a regenerated zinc oxide desulfurizer.

Embodiment 3

[0027] The regeneration method of zinc oxide desulfurization waste agent described in the present embodiment is:

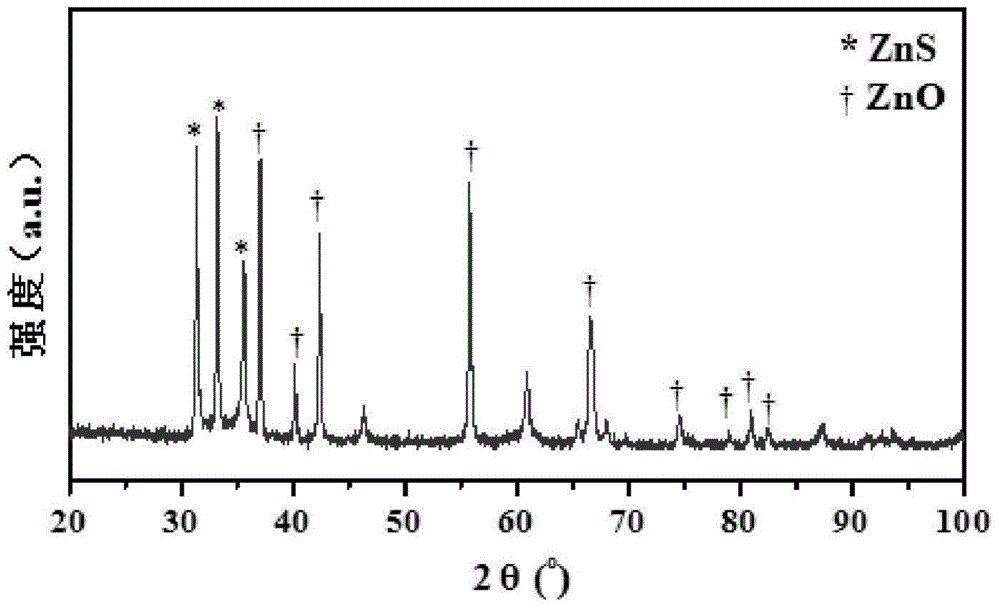

[0028] Add 1g of zinc oxide desulfurization waste agent, 50mL of deionization and 20mL of ammonia water to a 100mL hydrothermal reaction kettle in sequence, place the hydrothermal reaction kettle in an oven at 200°C for 24 hours, cool naturally after the reaction is completed, and dissolve the reaction solution Filter, collect the filter residue, wash the filter residue 6 times with deionized water, and dry at 110° C. for 10 hours to obtain a regenerated zinc oxide desulfurizer. Grind the regenerated zinc oxide desulfurizer into a powder of more than 200 mesh, and use XRD for structural characterization, such as figure 2 As shown, the diffraction peak changes of zinc oxide and zinc sulfide were observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com