Fully automatic vacuum injection molding control system and method

A vacuum injection molding and control system technology, applied in the field of a fully automatic vacuum injection molding control system and method, which can solve problems such as difficult product quality assurance, low production efficiency, and strong dependence on experience and proficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

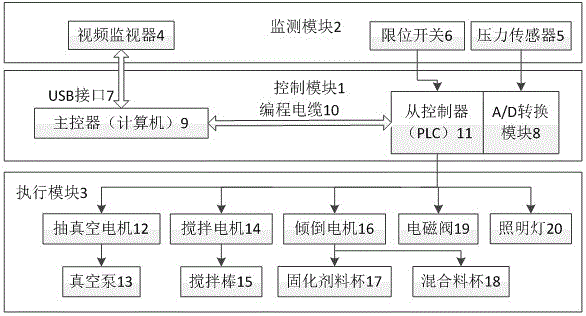

[0086] see figure 1 , the fully automatic vacuum injection control system consists of a control module, a monitoring module and an execution module, the control module is connected to the monitoring module and the execution module, and it is characterized in that: the control module consists of a main controller connected with a slave controller; the detection module is composed of a video monitor, two pressure sensors and four limit switches; the execution module is composed of a vacuum motor connected with a vacuum pump, a stirring motor connected with a stirring rod, Two pouring motors are respectively connected with a curing agent cup and a mixing cup, five solenoid valves, and a lighting lamp; in the control module, the main controller is a computer, and the slave controller is a programmable logic controller, which can The programming logic controller is connected to the computer through the SC-09 programming cable; the limit switch in the monitoring module is connected ...

Embodiment 2

[0088] The present embodiment is basically the same as the third embodiment, and the special features are as follows:

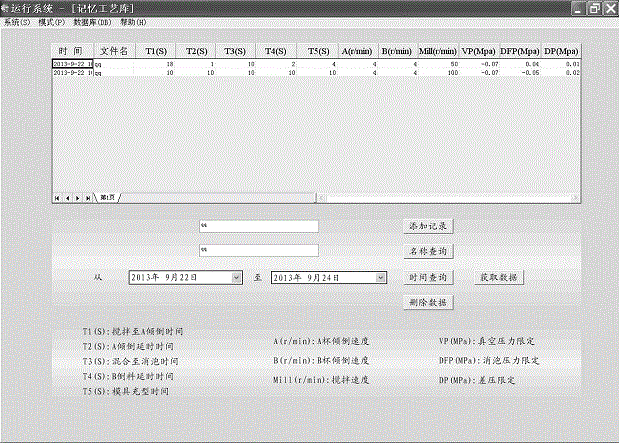

[0089]The main controller in the controller module is the computer receiving the collected images of the video monitor, and the real-time situation in the cabinet is reflected on the computer monitor; the pressure signal collected by the pressure sensor is processed by the A / D conversion module The programmable controller is sent to the programmable controller, and the programmable controller is sent to the computer through the programming cable to get the instruction of whether to stop vacuuming, and then sent to the programmable controller through the programming cable to control the start and stop of the vacuum pump, avoiding the Misoperation caused by manual observation of the vacuum table; the database access and process parameter setting part of the computer, the data in the matching database is obtained by manually inputting the name to query and match ...

Embodiment 3

[0091] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

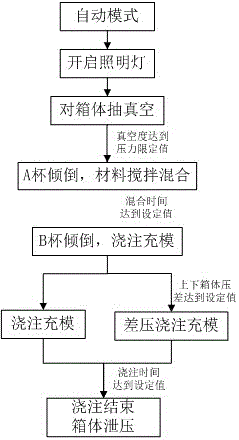

[0092] This embodiment takes the preparation of a thin-walled transparent plastic part (20g) with a complex cavity as an example, and introduces the specific implementation process of the automatic vacuum injection molding control system in detail with reference to the accompanying drawings.

[0093] 1. Connect the camera to the computer via the USB cable, and turn on the light source. Adjust the shooting angle so that the liquid level of the mixing cup is fully displayed in the monitoring window.

[0094] 2. Writing and downloading of the control program of the automatic vacuum injection molding machine:

[0095] Use the programming software GX-Developer to compile a fully automatic control program, in which the vacuum degree P1 is set to -0.095Mpa, and other process parameters such as stirring and pouring filling interval T0, A cup pouring time T1, A cup return and air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com