Method for improving electrochemical performance through reducing graphene oxide (GO) by using hydrogen (H2) and argon (Ar) mixed plasma

A hybrid plasma and plasma technology, applied in the field of reducing graphene oxide (GO) with hydrogen (H2) and argon (Ar) mixed plasma to improve electrochemical performance, can solve the complex process, time-consuming, introduction of impurities, etc. problem, to achieve the effect of improving the electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] one with H 2 A method for improving electrochemical performance by reducing GO with Ar plasma, comprising the following steps:

[0028] A. Ultrasonically disperse the 5 mg / mL GO solution uniformly, then spin-coat GO on the ITO conductive glass substrate with a spin-coater, the speed of the spin-coater is 3000 rpm, the spin-coating time is 90 s, and then placed at 60 ° Dry on a heating platform in C for 5 min to obtain a dried GO film;

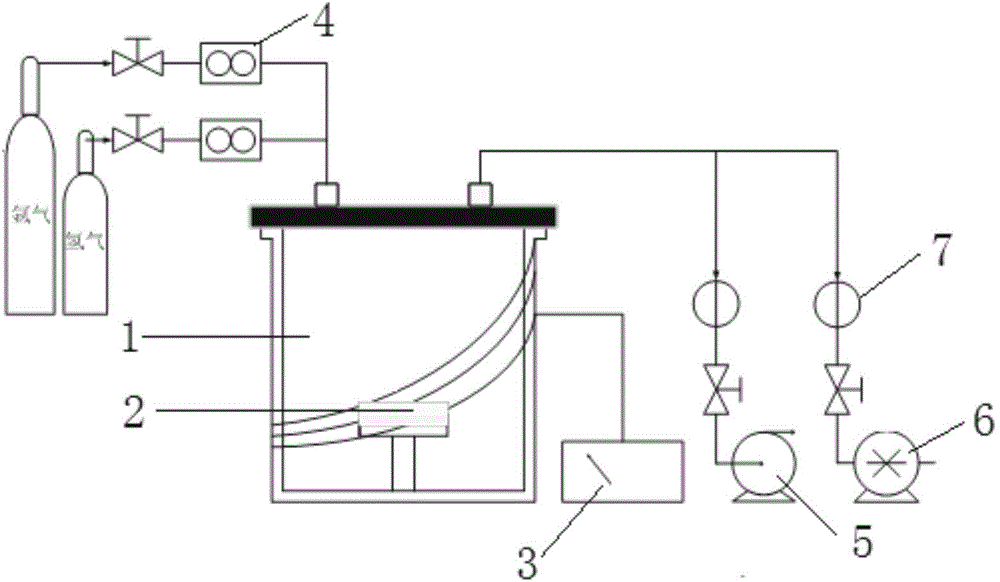

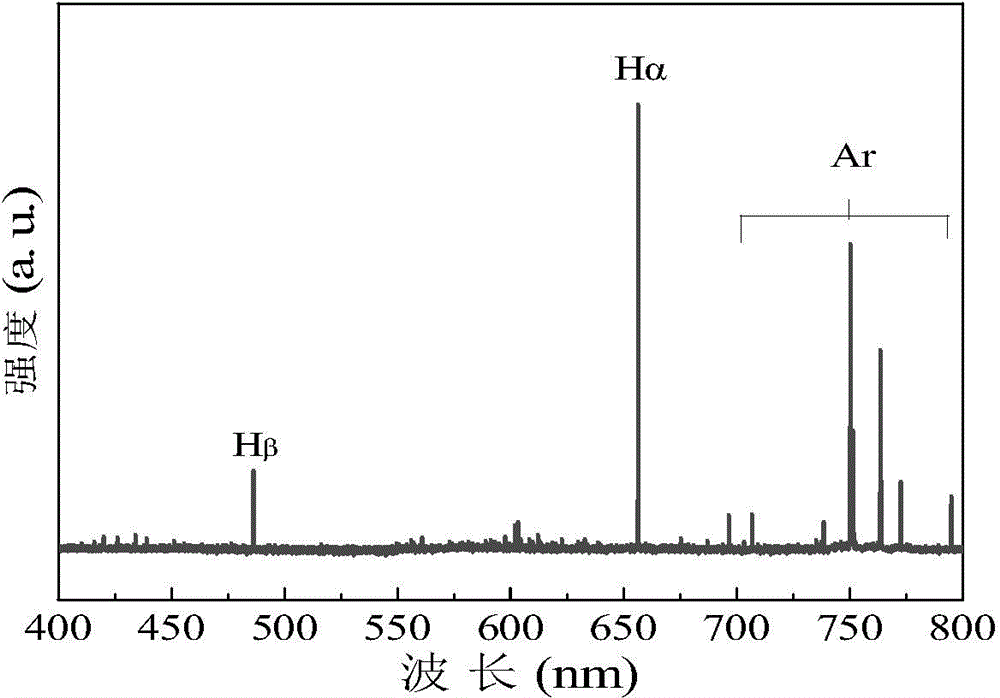

[0029] B, the ITO conductive glass that is loaded with GO thin film is placed in plasma discharge chamber 1 (see figure 1 ), the discharge chamber is connected with a graphite electrode 2, and the electrode is connected with an AC power supply 3, which can generate an inductively coupled plasma source. Argon gas is first introduced into the discharge chamber to drive away the air, and then the vacuum pump is turned on to evacuate to 2 Pa. At this time Turn on the AC power supply 3 to generate H 2 The mixed plasma flow with Ar is direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com