Constructed wetland system

A constructed wetland system and constructed wetland technology, applied in the field of sewage treatment, can solve the problems of filter blockage, long hydraulic retention time, and limited microbial action, and achieve the effects of strengthening, small footprint, and improving sewage treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

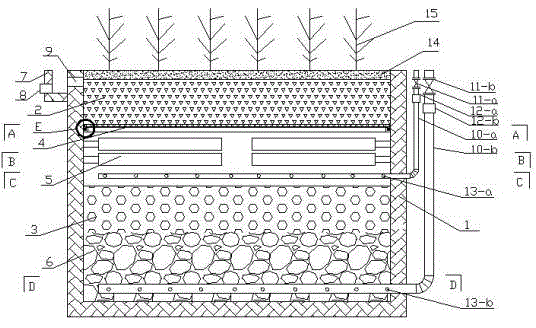

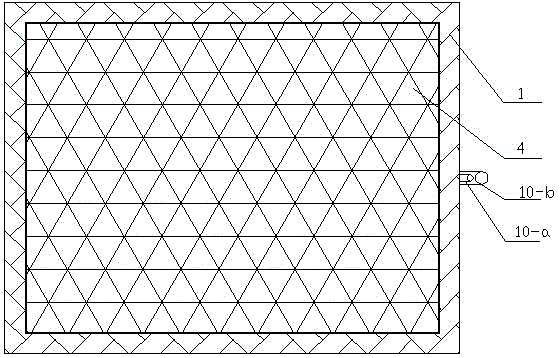

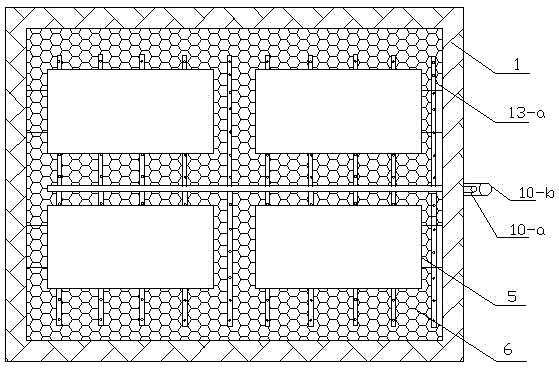

[0034] In a preferred embodiment, the constructed wetland pool body is 1.5m long, 1.2m wide, and 1.2m high; The distance from the bottom of the pool is 5cm, and the top of the gravel layer is 1cm~1.5cm of gravel; the artificial mixed matrix layer is 8mm~10mm thick, the thickness of the artificial mixed matrix layer is 30cm, the particle size of the sandstone is 3mm~7mm, and the thickness of the sandstone layer is 20cm , the thickness of the sandy soil layer is 10cm, and cattails are planted on the sandy soil layer; two layers of immobilized microbial plates are installed on the upper and lower sides of the immobilized microbial layer, and each layer is installed with 4 pieces. The size of each immobilized microbial plate: length × width × height: 45cm × 25cm ×6cm, the aeration device is installed on the upper end of the artificial matrix mixed layer at the lower end of the immobilized microbial plate, and the aeration branch pipe adopts microporous aeration; the water intake is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com