Method for preparing nano SiO2 composite starch/polyvinyl alcohol membrane

A polyvinyl alcohol film and composite starch technology, applied in the field of functional materials, can solve the problems of low mechanical strength, poor water resistance and wet strength, etc., and achieve the effects of less equipment investment, enhanced strength, and changed roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of starch film, the method step is as follows:

[0029] 1) Preparation of starch solution

[0030] Corn starch (Tianjin Zhongying Health Food Co., Ltd.) and deionized water (Motianmo Technology Co., Ltd., Tianjin University of Technology) were mixed in a certain proportion to form a 10% solution.

[0031] 2) Preparation of starch film

[0032] Place in a digital display magnetic stirrer (type 98-3, Gongyi Yingyu Instrument Factory) to heat up and stir at a certain speed. When the temperature of the solution reaches 95°C, control the temperature of the solution to be constant until the solution becomes clear, keep it warm for 1 hour, and make a film

[0033] 3) Preparation of starch porous membrane.

[0034] After the film was cooled to room temperature, it was poured into liquid nitrogen, frozen for 24 hours, and vacuum freeze-dried for 48 hours.

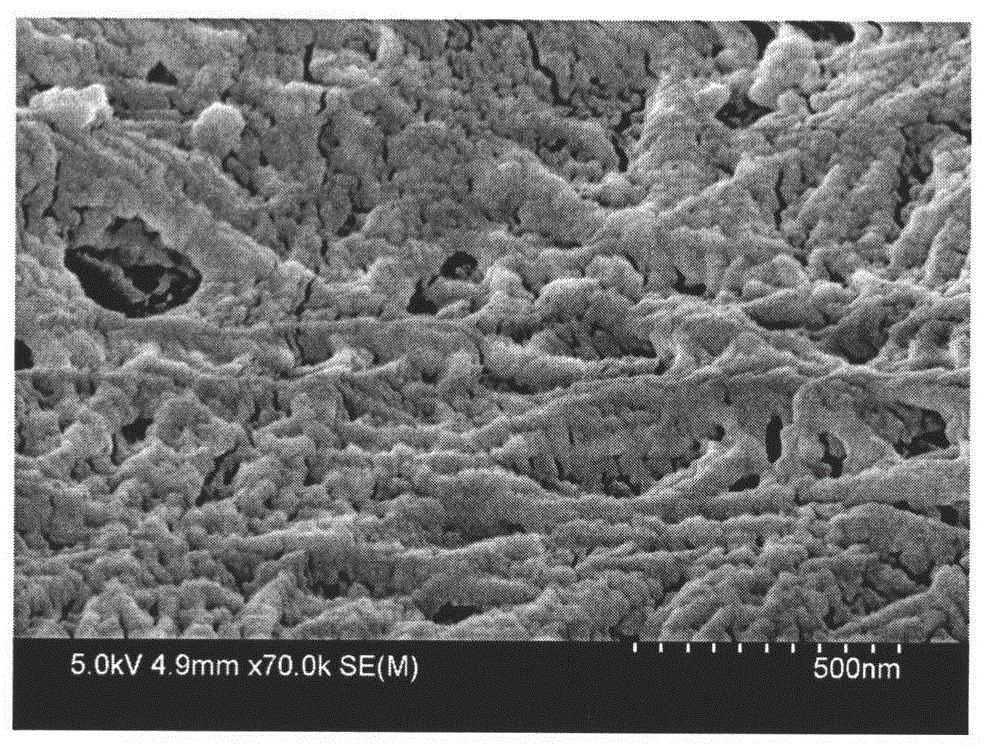

[0035] figure 1 It is a scanning electron microscope picture of the surface of the prepar...

Embodiment 2

[0037] A preparation method of starch / polyvinyl alcohol film, the method steps are as follows:

[0038] 1) Preparation of starch / polyvinyl alcohol solution

[0039] Cornstarch and polyvinyl alcohol (Tianjin Aoqi Medical and Pharmaceutical Sales Co., Ltd.) were mixed with deionized water at a mass ratio of 3:7 to prepare a 10% solution.

[0040] 2) Preparation of starch / polyvinyl alcohol film

[0041] Place on a digital display magnetic stirrer to heat up and stir at a certain speed. When the solution temperature reaches 95°C, control the solution temperature to be constant (be careful not to let the solution boil), until the solution becomes clear, keep it warm for 1 hour, and form a membrane.

[0042] 3) Preparation of starch / polyvinyl alcohol porous membrane

[0043] After the film was cooled to room temperature, it was poured into liquid nitrogen, frozen for 24 hours, and vacuum freeze-dried for 48 hours.

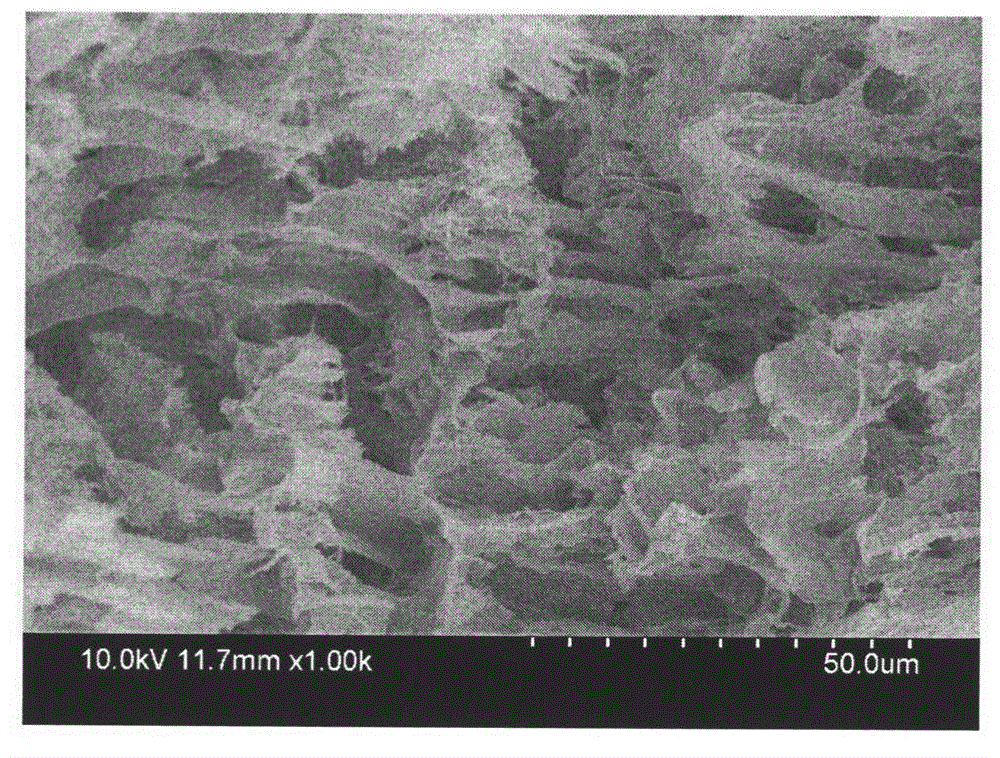

[0044] figure 2 is the scanning electron microscope picture o...

Embodiment 3

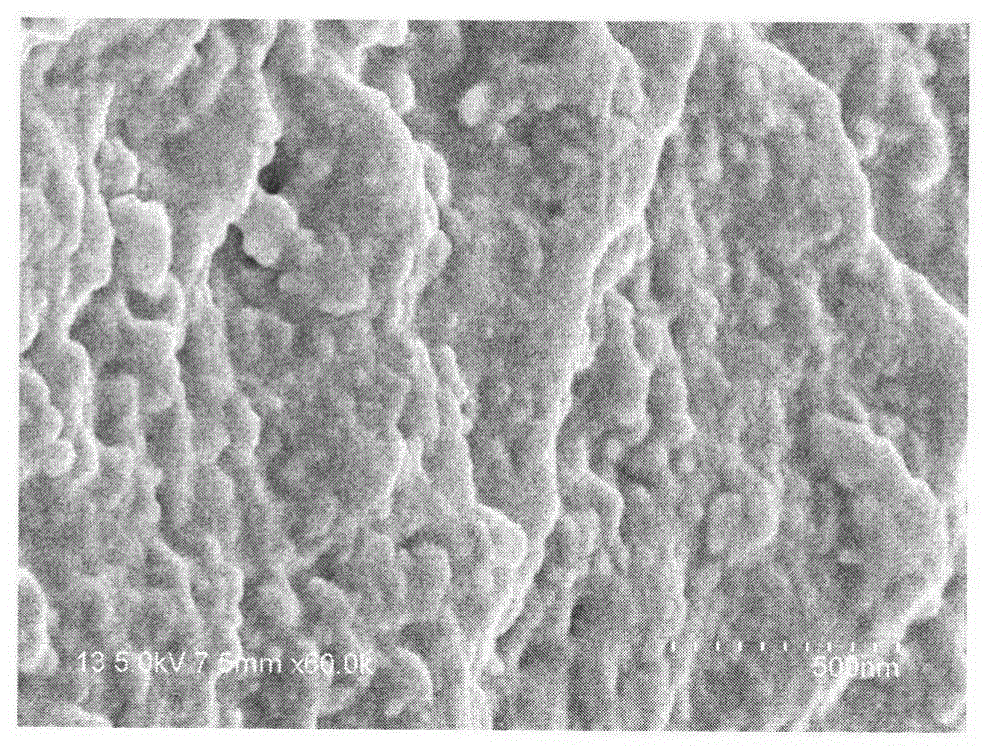

[0046] A SiO 2 / starch film or SiO 2 The preparation method of the preparation of / starch / polyvinyl alcohol film, this method step is as follows:

[0047] 1)SiO22 / starch solution or SiO 2 / Preparation of starch / polyvinyl alcohol solution

[0048] nano-SiO 2 Placed in the water phase, ultrasonically dispersed for 60 minutes to break up aggregates and form relatively stable nano-SiO 2 Water dispersion system, its addition amount is 2% of the dry weight of starch / polyvinyl alcohol (or starch), and then starch / polyvinyl alcohol (or starch) is added to SiO in a certain proportion 2 In the solution, make a 10% solution, and stir and disperse at a high speed for 15 minutes at room temperature to prevent SiO 2 reunited again

[0049] 2)SiO2 2 / starch film or SiO 2 / Starch / polyvinyl alcohol film preparation

[0050] Place on a digital display magnetic stirrer to heat up and stir at a certain speed. When the solution temperature reaches 95°C, control the solution temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com