Glass fiber cloth heat-conducting double-faced adhesive tape

A technology of thermally conductive double-sided tape and glass fiber cloth, applied in the field of double-sided tape, can solve the problems that the thermal conductivity cannot meet certain requirements, the general requirements of the electronics industry, and the technology is not mature enough to achieve good viscosity and dispersion. Good performance, good glue cohesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

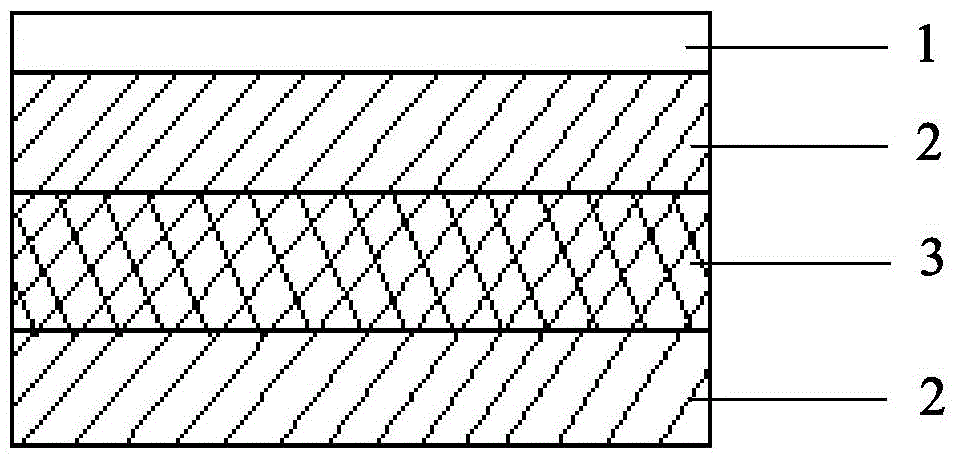

[0026] like figure 1 As shown, the present invention provides a thermally conductive double-sided adhesive for glass fiber cloth, comprising:

[0027] Substrate 3, choose a plain weave shape glass fiber fabric layer;

[0028] The thermally conductive adhesive layer 2 is a layer of thermally conductive adhesive coated on the surface of the base material layer by means of blade transfer coating.

[0029] The glass fiber cloth thermally conductive double-sided adhesive further includes a release paper 1 attached to one side of the thermally conductive adhesive layer 2 , and the release paper 1 is PE coated paper.

[0030] The glass fiber cloth fabric layer is one of alkali-free glass fiber, medium-alkali glass fiber and high-alkali glass fiber, chemical-resistant glass fiber, hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com