A kind of production method of optically pure r-acetoin

A production method and technology of acetoin, applied in the field of high-efficiency production of optically pure R-acetoin, can solve the problems of low R-acetoin yield, low optical purity, and high cost, and achieve simple operation process and simple culture medium , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

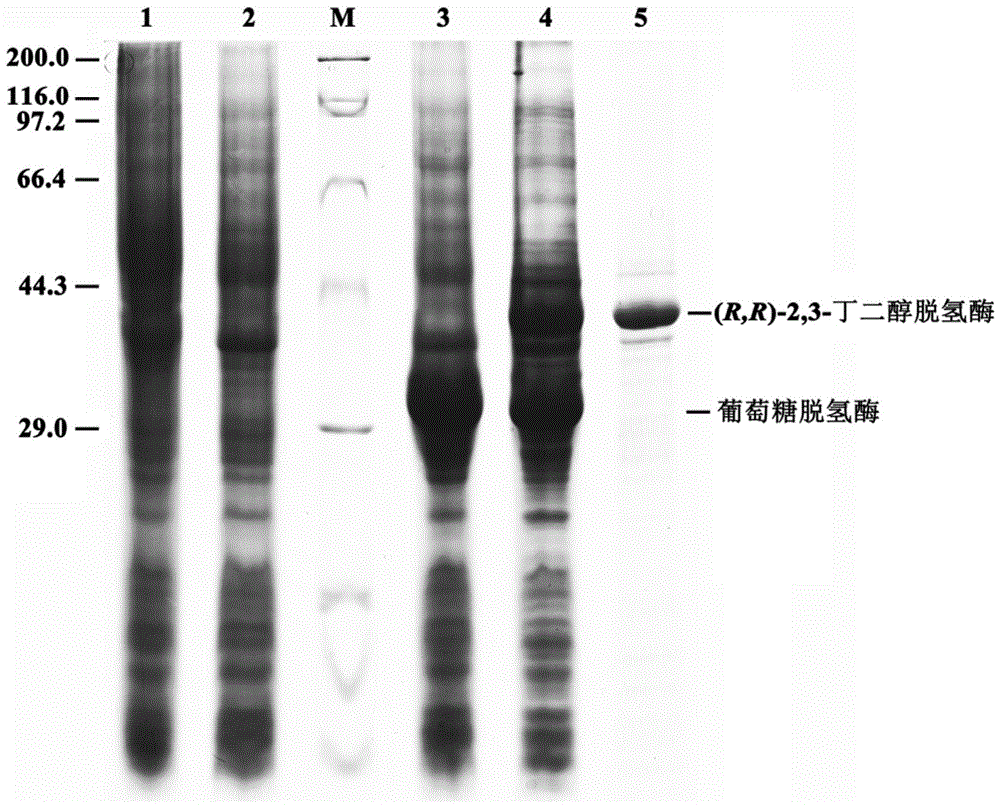

[0038] Construction of recombinant Escherichia coli BL21 / pETDuet-bdh-gdh

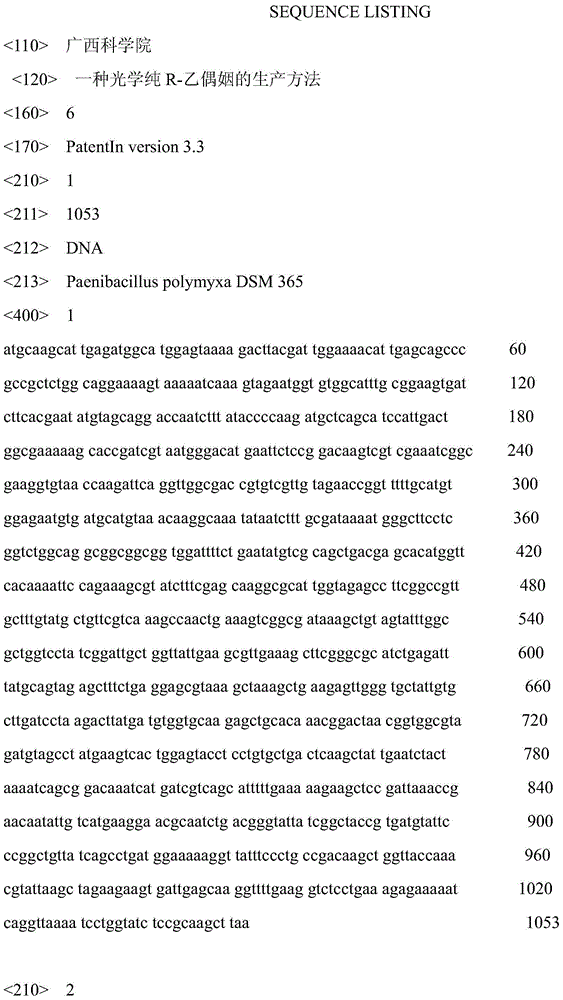

[0039] Genomic DNA of the strain Paenibacillus polymyxa DSM365 was prepared by conventional methods, the genome of the strain was sequenced and metabolic network analysis was carried out, and related genes were annotated and functionally identified, and the (R,R)-2 of the strain was obtained, Coding sequence of 3-butanediol dehydrogenase gene; (R,R)-2,3-butanediol dehydrogenase was amplified by PCR using synthetic primers P1 and P2, using genomic DNA of P.polymyxa DSM365 as a template Hydrogenase gene (bdh). The genome sequence of the Bacillus subtilis168 strain was obtained from the NCBI database. The glucose dehydrogenase gene (gdh) was amplified by PCR using the synthetic primers P3 and P4 and using the genomic DNA of B. subtilis168 as a template.

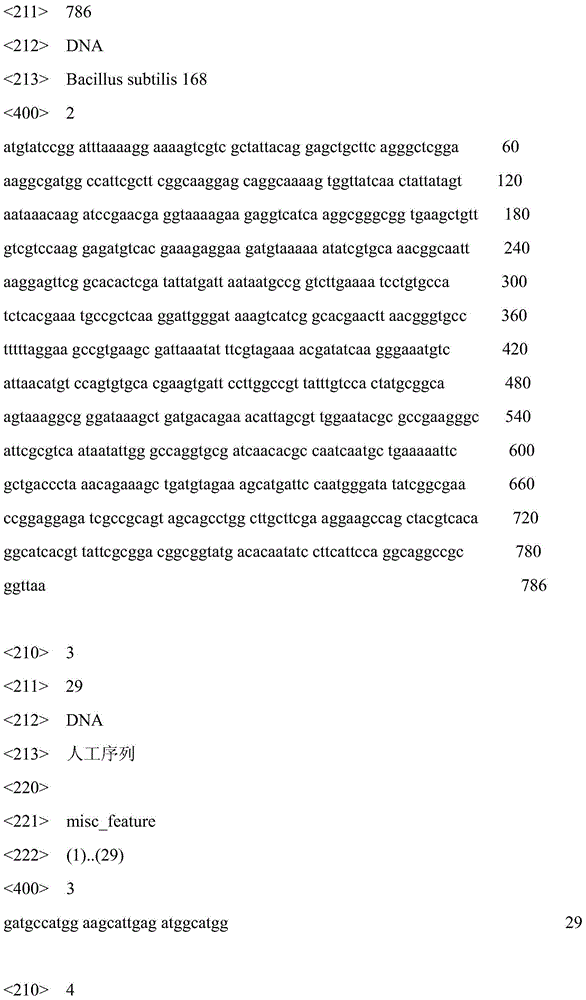

[0040] The sequences of P1, P2, P3 and P4 are respectively:

[0041] P1: 5'-GATGCCATGGAAGCATTGAGATGGCATGG-3';

[0042] P2: 5'-TCGCGAGCTCTTAAGCTTGCGGAG...

Embodiment 2

[0049] Preparation of Recombinant Escherichia coli Resting Cell Biocatalyst

[0050] (1) Plate culture: Streak the recombinant Escherichia coli BL21 / pETDuet-bdh-gdh onto an LB plate containing 1.8% agar by mass volume ratio and containing 100 μg / mL ampicillin, and culture at 37° C. for 12 hours;

[0051] (2) Seed culture: under sterile conditions, use a toothpick to pick a single colony on the plate of step (1), and then inoculate it into 20 mL of LB liquid medium containing 100 μg / mL ampicillin, shake it at 37 ° C Shake culture for 12 hours;

[0052] (3) Fermentation tank culture: under sterile conditions, take the bacterial solution obtained in step (2) and inoculate it into 2 L of LB liquid medium containing 100 μg / mL ampicillin at an inoculum size of 1% by volume, and cultivate at 37 ° C 3 hours, then add IPTG with a final concentration of 0.5mM, induce for 10 hours at 16°C, and stop the culture;

[0053] Wherein, the LB medium formula described in the above steps (1) to...

Embodiment 3

[0056] Preparation of Optically Pure R-Acetoin Using Recombinant Escherichia coli Resting Cells as Biocatalyst

[0057]Select the recombinant Escherichia coli resting cells obtained above as a catalyst to carry out the following transformation process: at 30°C and pH 7, shake on a 180rpm shaker, convert diacetyl with an initial concentration of 20g / L, and add 20g / L of glucose to supplement Consumption of cofactors required for the reaction; samples were taken every 3 hours, and the samples were centrifuged at 8,000rpm for 10 minutes to remove the added whole-cell biocatalyst, and the concentration of diacetyl in the supernatant was detected by gas chromatography. According to the concentration of diacetyl Diacetyl was added to maintain the diacetyl concentration between 10 and 20 g / L; the supernatant was analyzed by gas chromatography to determine the concentration and optical purity of R-acetoin in the conversion solution; after 16 hours, the test results showed: The concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com