Mining scrapping plate integral induction heat-permeable segmented time-controllable spray quenching process and device

A technology of induction diathermy and scraper, applied in quenching device, process efficiency improvement, heat treatment furnace, etc., can solve the problems of long production cycle, prolonged production cycle, high cost, and achieve the effect of low-cost production and pollution-free production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

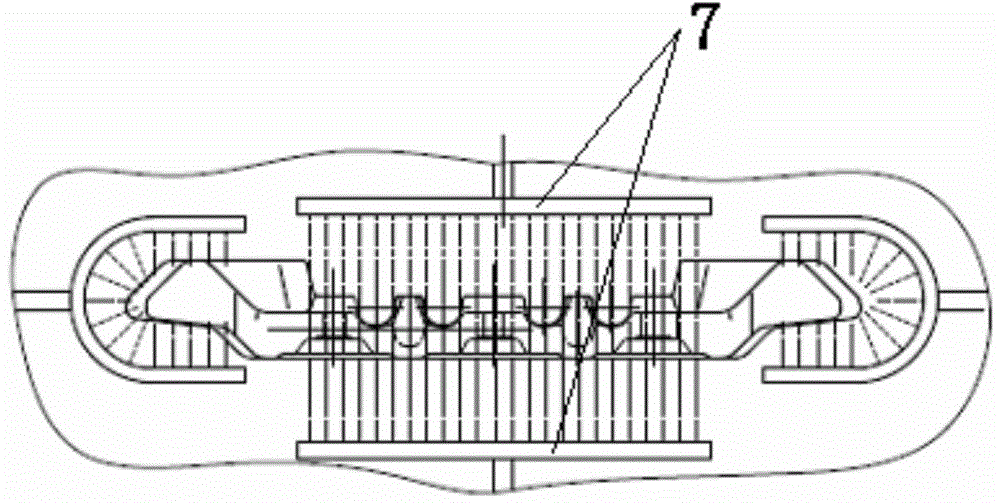

Method used

Image

Examples

Embodiment 1

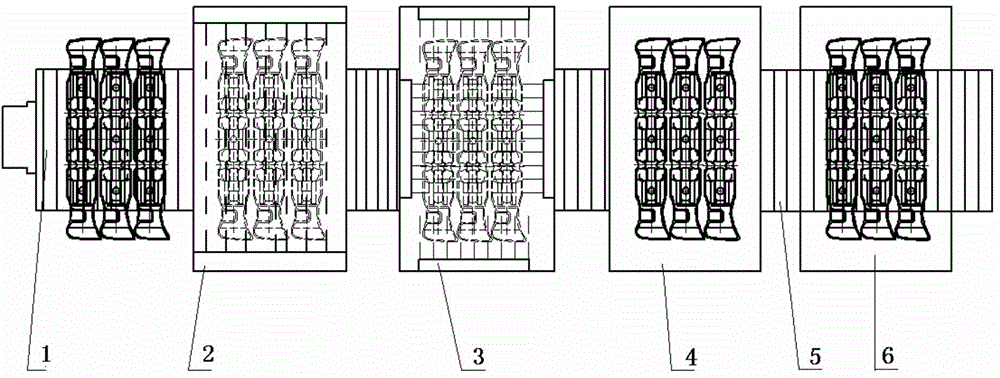

[0032] Take the product 118SD-01 scraper (40Mn2) of Ningxia Tiandi Benniu Industrial Group Co., Ltd. as an example below, and use the overall induction diathermy segmental time-controlled quenching process of the present invention to process, and its specific process parameters are as follows:

[0033] 1. Induction diathermy furnace 2 heating:

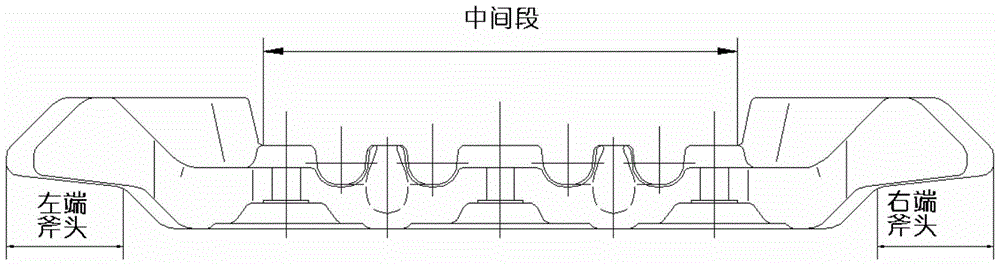

[0034] 1) Quenching temperature: The heating temperature of the scraper (semi-finished product) heated in the induction diathermy furnace 2 is determined by the induction heating power, frequency and time. Specifically, the temperature of the middle section of the scraper is 900-940°C. The temperature of the ax is 840-880°C.

[0035] 2) Heating time: For 118SD-01 scraper (40Mn2), 3 pieces are heated each time, and the heating time is 12 minutes.

[0036] 3) Beats: 3 pieces of scrapers are installed in each beat, and the pushing table 1 is sent into the induction diathermy furnace 2 at a 12-minute beat, and its position is basically un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com