Electrical control management unit for engine fuel gas

A management unit and engine technology, applied in engine control, machine/engine, electrical control, etc., can solve problems such as difficulty in ensuring control and optimization of combustion to meet standards, inaccurate judgment of ignition effectiveness, and easy fluctuations in voltage values. Heating driving ability, meeting high standard emission requirements, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

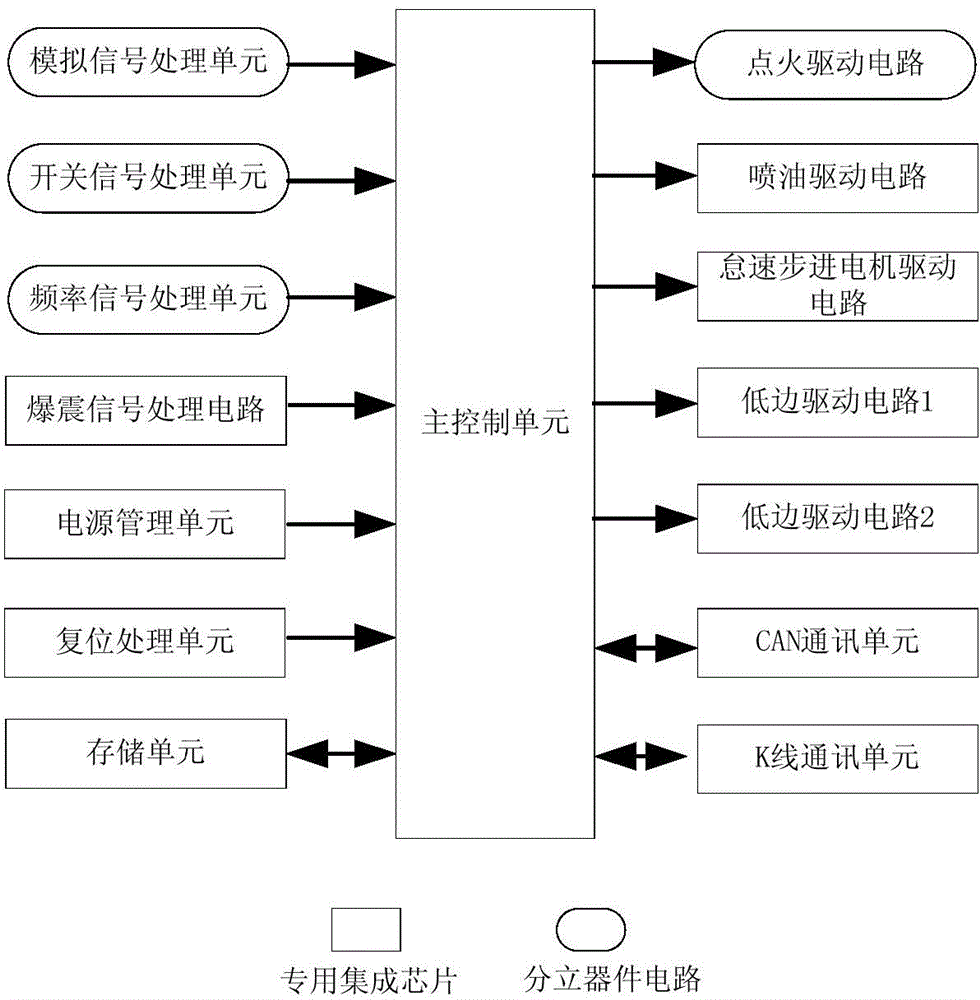

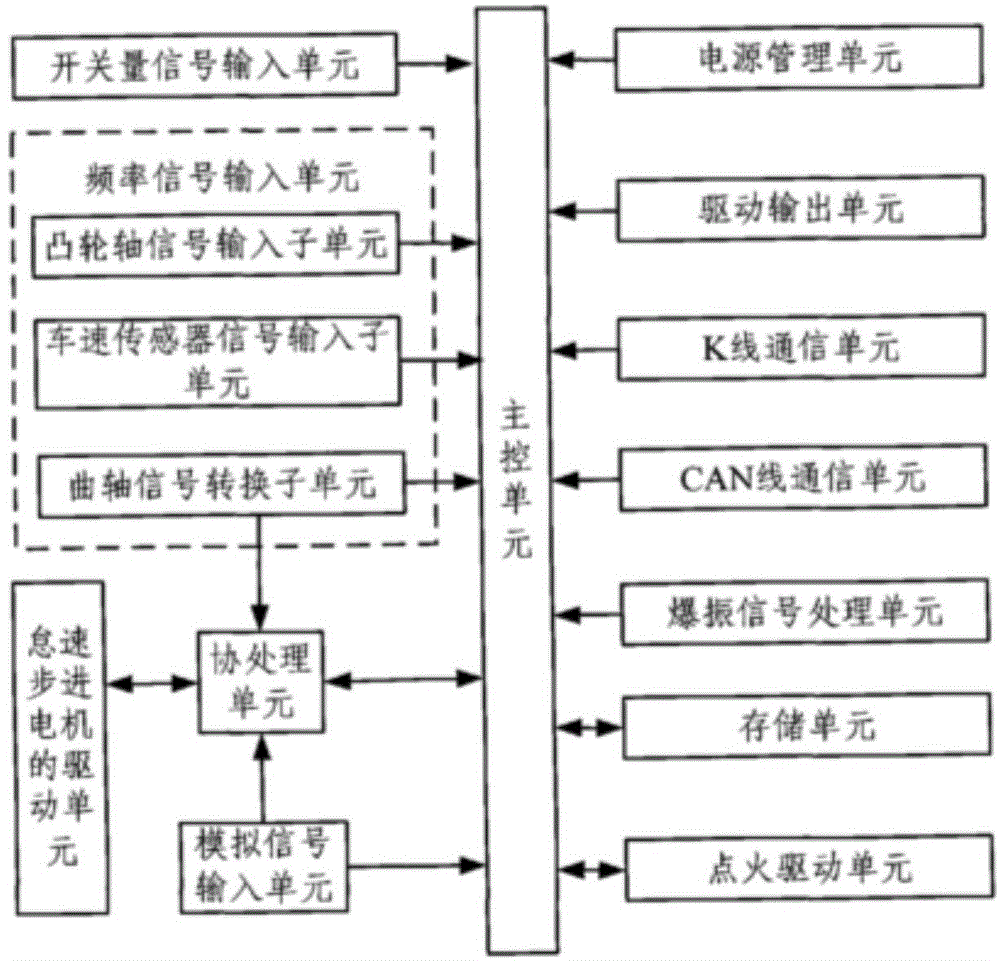

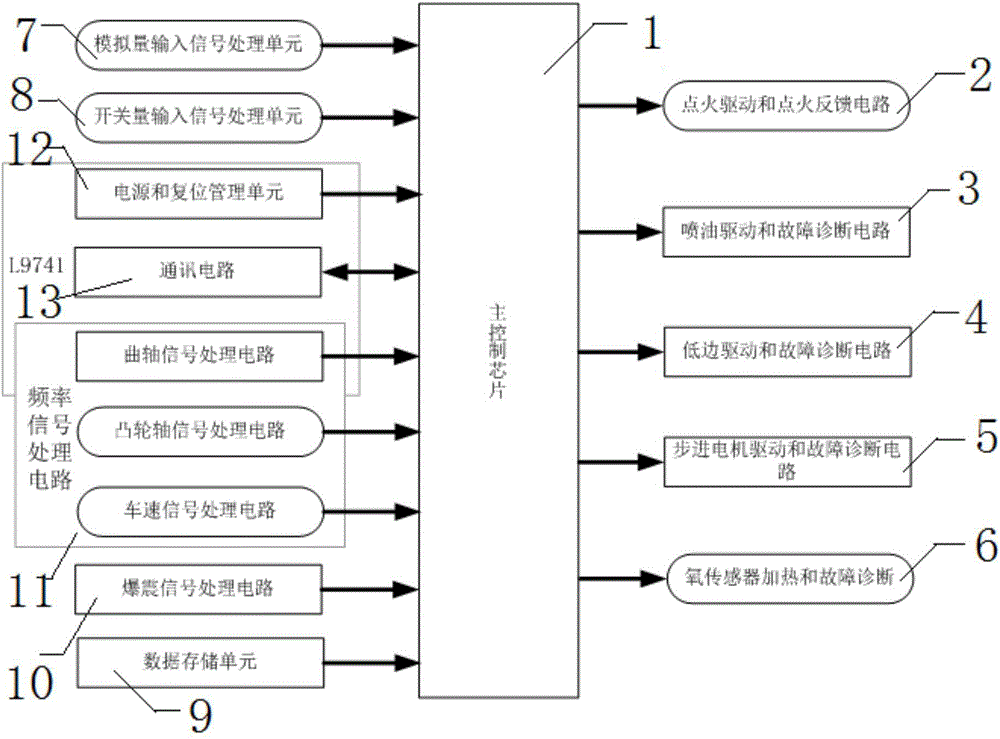

[0056] Such as image 3 As shown, the engine gas electronic control management unit of the present invention includes a main control unit 1, an ignition drive and an ignition feedback circuit 2 connected to the main control unit 1, a fuel injection drive and a fault diagnosis circuit 3, a low-side drive and a fault diagnosis circuit 3, and a main control unit 1. Diagnosis circuit 4, stepper motor drive and fault diagnosis circuit 5, oxygen sensor heating and fault diagnosis circuit 6, analog input signal processing unit 7, switch input signal processing unit 8, data storage unit 9, knock signal processing unit 10 , frequency signal processing circuit 11, power supply and reset management unit 12 and communication unit 13, to realize the management and control of each unit circuit by the main control chip;

[0057] Such as Figure 4 with Figure 5 As shown, the main control unit 1 adopts a high-performance 16-bit microcontroller C167CS main control chip, and is externally con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com