Pressure backfill type elastic buried pipe construction method

A construction method, penstock technology, applied in filling, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve problems affecting ground vegetation and normal use, complex stress conditions, and large environmental damage, etc., to achieve The effect of improving design and construction technology level, fast construction progress and shortening excavation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

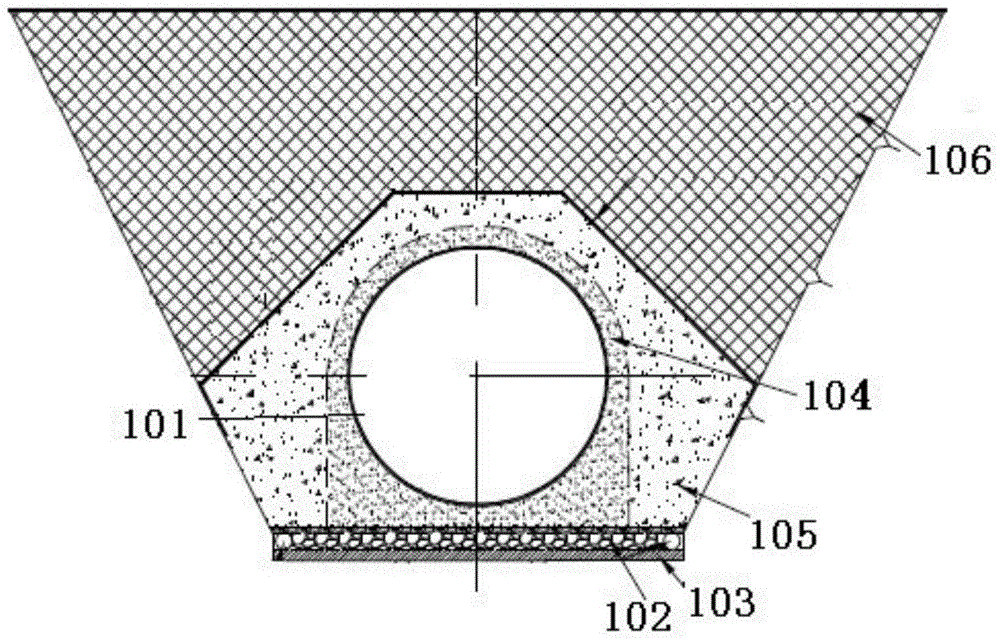

[0034] see figure 1 , shows a schematic cross-sectional view of the pressure backfill elastic buried pipe construction method of the present invention.

[0035] In order to avoid the impact on the environment and reduce the steel pipe outsourcing concrete and buttress structures as much as possible, the present invention selects relatively shallow pipe grooves and elastic buried pipes, and adopts the following steps:

[0036] Step 1: pipe groove excavation and support

[0037] (1) For earthwork excavation, measure the ground line required for excavation, and then directly excavate through the trench excavation method after removing vegetation, and dig out soil and gravel materials. For slope stability and engineering construction, an intercepting ditch parallel to the pipe groove is arranged outside 2m from both sides of the excavation line. Preferably, the size of the intercepting ditch is 50cm×50cm;

[0038] (2) Stonework excavation is carried out by drilling and blasting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com