Screw pressing dewaterer for sludge dewatering

A technology of screw pressing and sludge dewatering, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc. It can solve the problems of long processing cycle and large energy consumption, achieve low operating power and save operation control. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A method for sludge treatment, comprising the steps of:

[0035] a Adjust the moisture content of the sludge to 60-70%,

[0036] b carry out low-temperature pyrolysis of the sludge obtained in a, and collect the pyrolysis gas,

[0037] c. Heat the pyrolysis residue after the treatment in step b to 1300~1500°C to burn the organic matter in the sludge,

[0038] d Use the residue after combustion as an inorganic additive to make glass or cement.

[0039] The following is a detailed description of each step:

[0040] The sludge from the sewage treatment plant was taken, and its water content was measured to be 97.3%. It was concentrated by a screw press dehydrator, and the water content was adjusted to 60-70%.

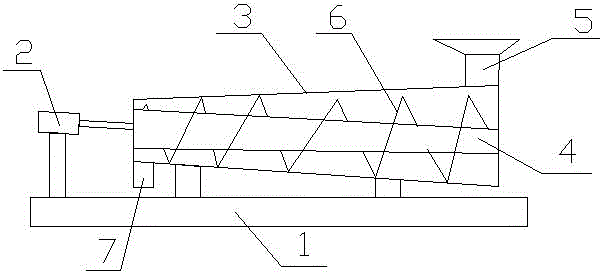

[0041] The screw press dehydrator used includes a frame body, a driving device, a screw column, a screen drum, and a screw blade. The drive device and the screen drum are fixed on the frame body, the screw column is arranged in the screen drum, and the screw blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com