Efficient denoising handheld electric saw

A handheld and high-efficiency technology, applied in sawing machine devices, metal sawing equipment, sawing machine tools and other directions, can solve the problems that affect the smooth development of on-site work, the noise reduction effect is not obvious, and the physical and mental health hazards, etc. The effect of strengthening strength and reducing dustiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

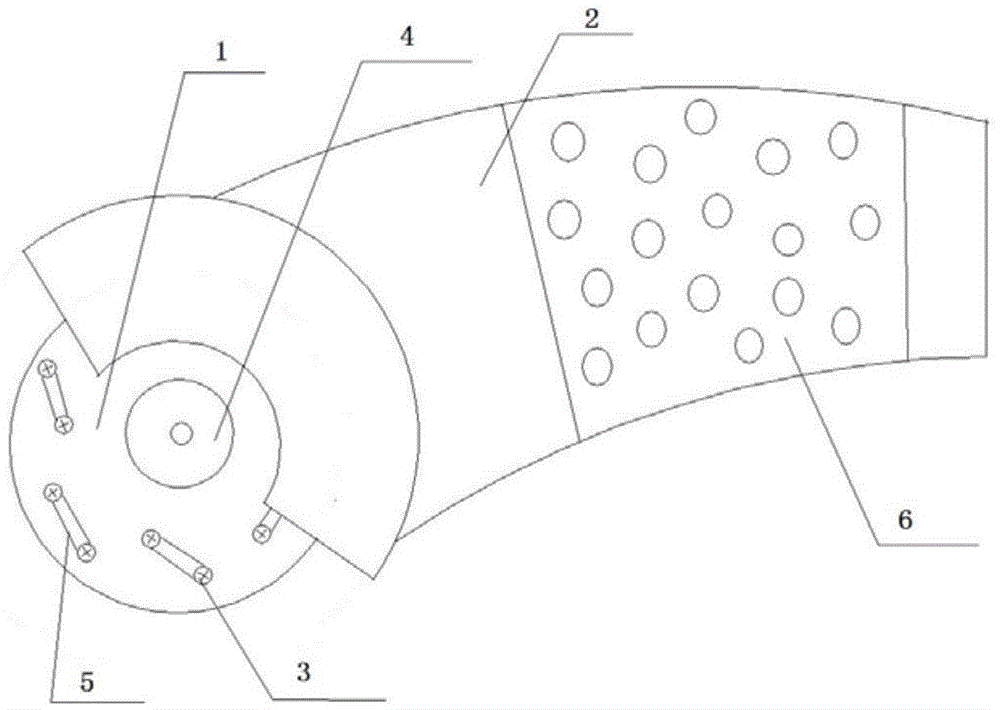

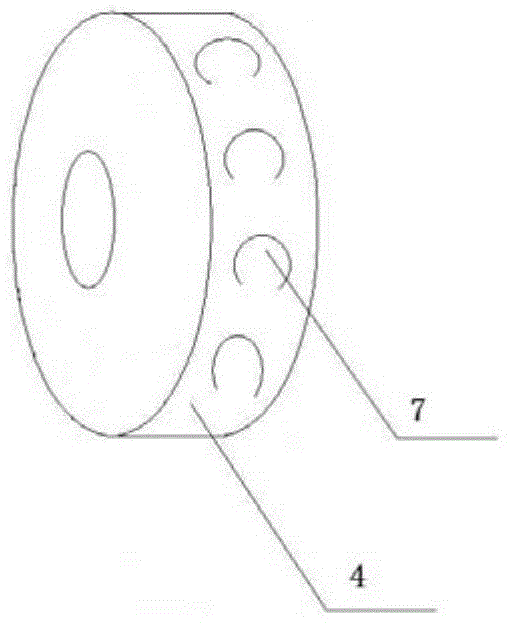

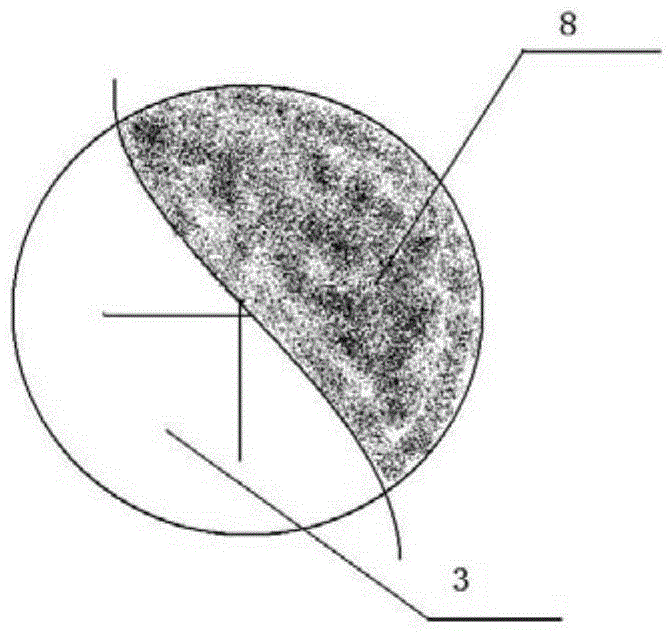

[0021] combine figure 1 , the high-efficiency noise-reducing hand-held electric saw of the present invention includes a saw blade 1 and a hand-held part 2, the saw blade end of the hand-held part 2 is connected to the saw blade 1 through a rotating shaft, and a motor is provided inside the hand-held part 2 for Drive the saw blade 1 to rotate; the saw blade 1 is provided with 12 holes 3, the holes 3 are unevenly and asymmetrically distributed on the saw blade 1, and the inside of the hole 3 is filled with powder material 8 ( Such as image 3 shown), and the powder material 8 is sealed in the hole through the nut, the material of the nut is copper, and the powder material 8 is copper powder, which can effectively absorb the energy generated by vibration, so as to reduce vibration and reduce The purpose of the noise, and the nut can streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com