Dy (III)-Ni (II) mixed-metal magnetic complex constructed by mixed ligand as well as preparation method and application of complex

A technology of mixed ligands and complexes, applied in the fields of magnetism and organic chemistry of organic materials/organic magnetic materials, can solve problems such as limited research, achieve good reproducibility, high thermal stability, phase purity, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

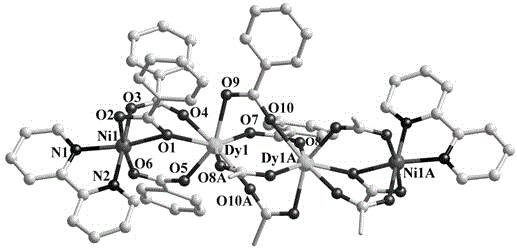

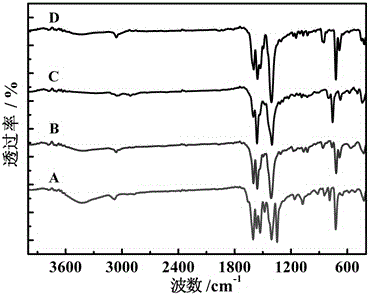

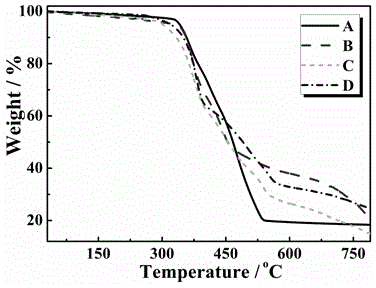

[0027] Dy(III)-Ni(II) mixed-metal magnetic complexes based on o-phenanthroline and m-nitrobenzoic acid as mixed ligands A Synthesis:

[0028] O-phenanthroline (0.1 mmol, 19.8 mg), m-nitrobenzoic acid (0.3 mmol, 50.1 mg), nickel nitrate hexahydrate (0.1 mmol, 29.1 mg) and dysprosium nitrate hexahydrate (0.2 mmol, 91.3 mg) was dissolved in double-distilled water (8.0 mL), adjusted to pH 5 with NaOH, stirred for several minutes, and sealed in a hydrothermal kettle. After incubation at 160°C for four days, at 3.0°C·h –1 The rate program cooled down to room temperature to obtain green blocky crystals, which were then washed with twice distilled water and dried in air.

Embodiment 2

[0030] Dy(III)-Ni(II) mixed-metal magnetic complexes based on o-phenanthroline and benzoic acid as mixed ligands B Synthesis:

[0031] O-phenanthroline (0.1 mmol, 19.8 mg), benzoic acid (0.3 mmol, 36.6 mg), nickel nitrate hexahydrate (0.1 mmol, 29.1 mg) and dysprosium nitrate hexahydrate (0.2 mmol, 91.3 mg) Dissolve in twice distilled water (8.0 mL), adjust the pH to 5 with NaOH, stir for several minutes, and seal it into a hydrothermal kettle. After incubation at 170°C for four days, at 3.0°C·h –1 The rate program cooled down to room temperature to obtain green blocky crystals, which were then washed with twice distilled water and dried in air.

Embodiment 3

[0033] Dy(III)-Ni(II) mixed-metal magnetic complexes based on 2,2′-bipyridine and benzoic acid as mixed ligands C Synthesis:

[0034] 2,2′-bipyridine (0.1 mmol, 15.6 mg), benzoic acid (0.2 mmol, 24.4 mg), nickel nitrate hexahydrate (0.1 mmol, 29.1 mg) and dysprosium nitrate hexahydrate (0.2 mmol, 91.3 mg) was dissolved in double distilled water (10.0 mL), adjusted to pH 6 with NaOH, stirred for several minutes, and sealed into a hydrothermal kettle. After incubation at 170°C for four days, at 3.0°C·h –1 The rate program cooled down to room temperature to obtain green blocky crystals, which were then washed with twice distilled water and dried in air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com