Preparation method of adhesive for FSC (forest stewardship council) corrugated board

A technology of corrugated cardboard and adhesives, applied in the direction of adhesive types, starch adhesives, polymer adhesive additives, etc., which can solve the problems of unsatisfactory printing effect, decreased proportion of raw paper wood pulp, and adhesive strength To achieve the effect of solving poor bonding, improving penetration and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A method for preparing an adhesive for corrugated cardboard that meets FSC certification standards, comprising the following steps:

[0016] (1) Preparation of carrier paste: Put 330kg of water into the carrier tank at one time, heat it to 38°C, then put in 40kg of starch at one time, stir while adding, and then gradually add 25kg of liquid alkali, add while adding Stirring, followed by 12000 rpm high-speed shearing treatment to obtain carrier paste;

[0017] (2) Preparation of the main glue: Put 600kg of water in the main tank at one time, heat it to 38°C, put the carrier paste into the main tank, then gradually put in 290kg of starch, stir while adding, and then gradually put in 14kg of glue Combine the strengthening agent, stir while adding, after adding the adhesion enhancing agent, throw in 3.5kg of borax at one time, stir for 12 minutes, and obtain the main glue;

[0018] (3) After the mixture in the main tank is fully stirred evenly, the temperature of the collo...

Embodiment 2-4

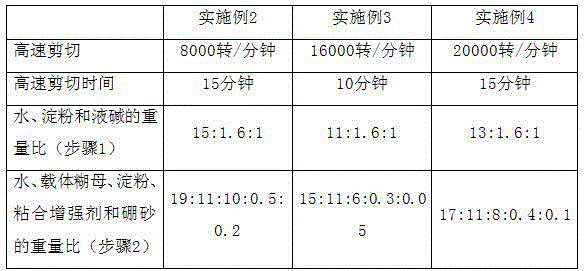

[0028] Except following parameter, other method and parameter are with embodiment 1

[0029]

[0030] Example of effect

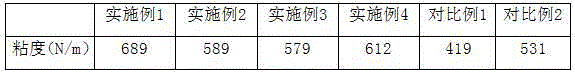

[0031] The adhesives prepared in the above examples and comparative examples were applied to the sizing of FSC corrugated cardboard, and the prepared corrugated paper had the same composition except for different adhesives.

[0032] The national standard GB / T6548-2011 method for the determination of the adhesive strength of corrugated cardboard was used to measure the adhesive strength of corrugated cardboard. The specific results are as follows:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com