A critical safety control method for a dissolver with ring-shaped solid neutron poison partition layout

A criticality safety and control method technology, applied in the direction of reducing greenhouse gases, reactor fuel elements, reactors, etc., can solve the problems that the feeding amount affects the criticality safety, affects the shear heat chamber, and affects the ventilation system, etc., to solve the problem of criticality safety control , increase the cross-sectional area and loading capacity, and improve the effect of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

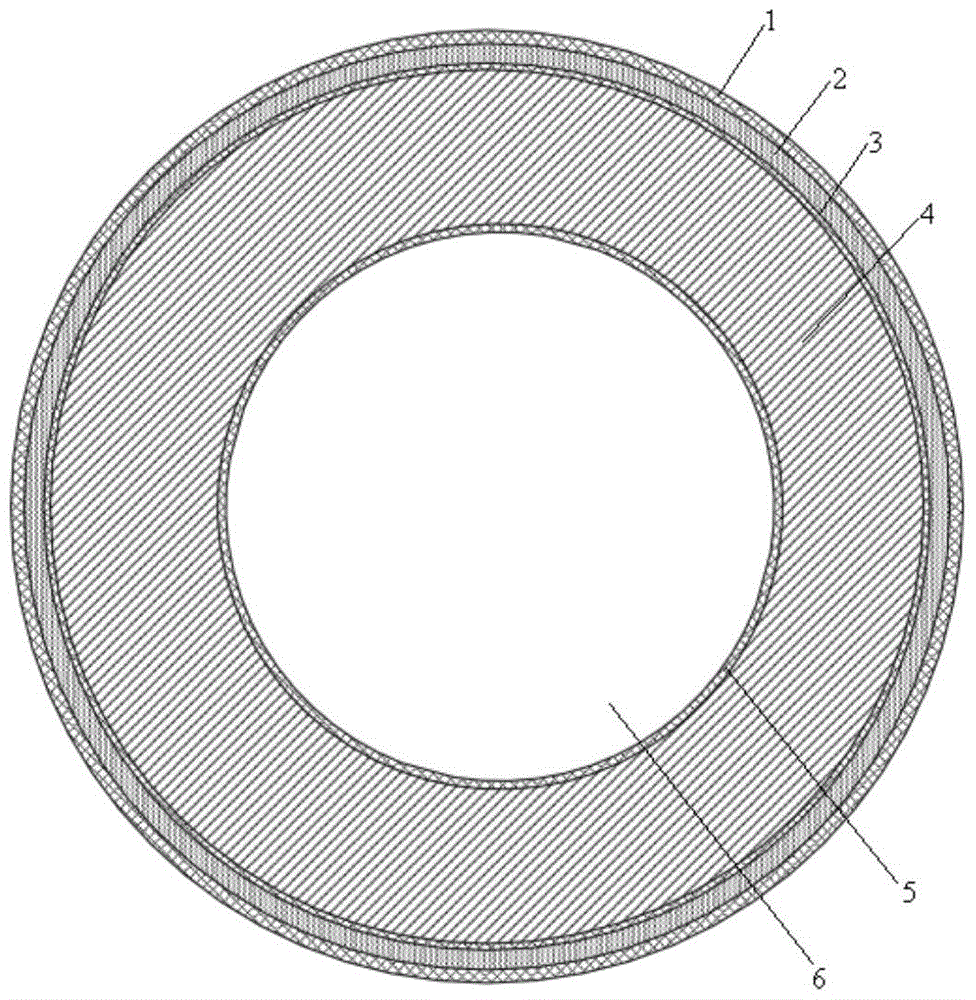

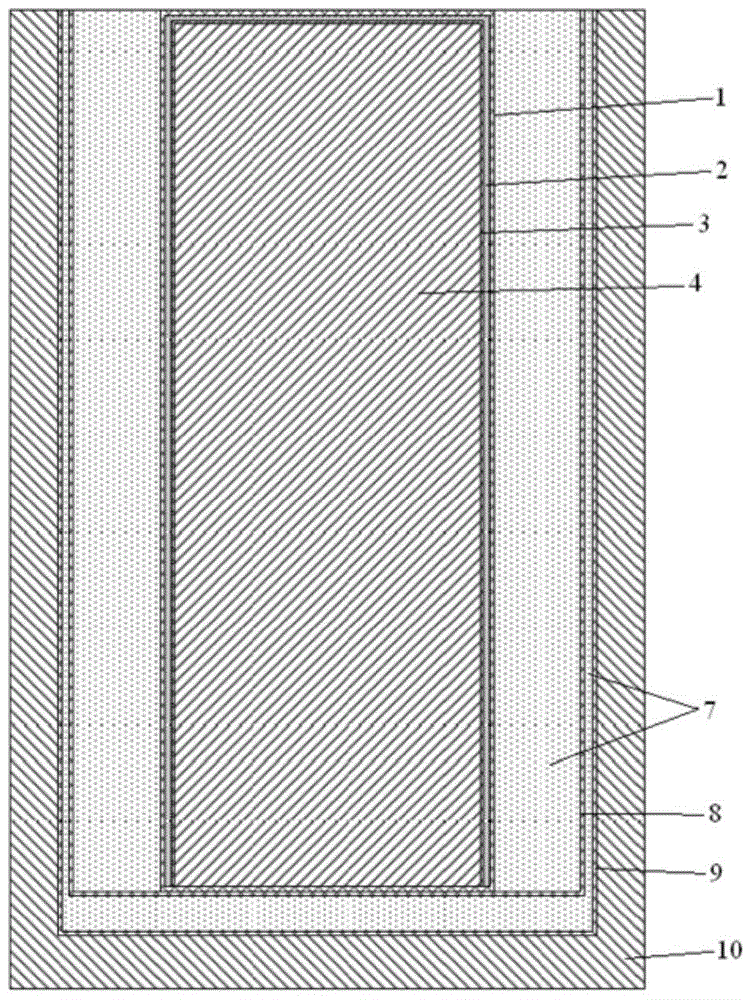

[0021] The dissolver provided by the present invention includes a large hanging basket placed in the solution in the wall of the dissolver, and a solid neutron poison partition structure is arranged in the large hanging basket, and the solid neutron poison partition structure includes an annular neutron poison layer and a neutron poison partition structure. The moderator material is encapsulated and separated by cladding, and the ring-shaped solid neutron poison partition structure is arranged in the center of the large hanging basket, so as to achieve the purpose of controlling criticality safety.

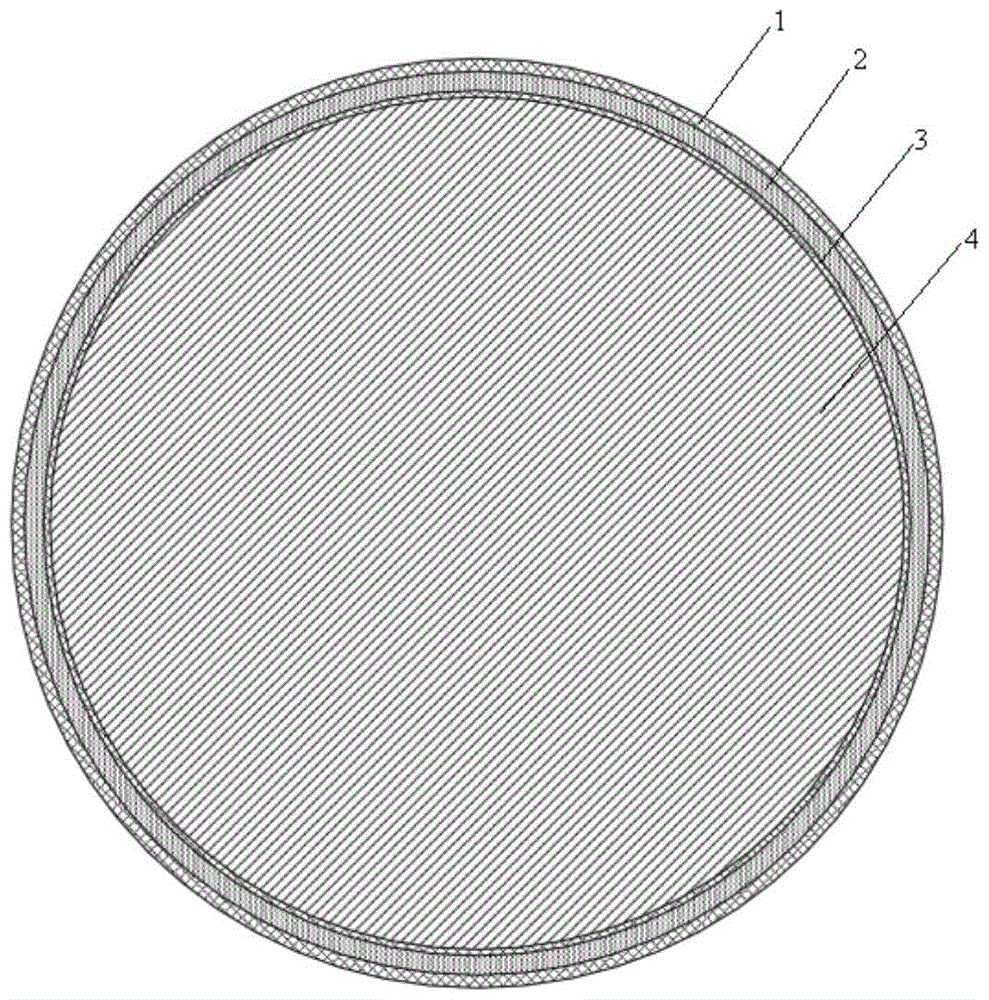

[0022] figure 1 It is a cross-sectional schematic diagram of the partition structure of solid neutron poison. The neutron poison layer 2 is an annular layered structure with encapsulation and separation inside and outside respectively. The neutron moderat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com