High-salt reservoir enhanced foam flooding composition and preparation method

A composition and foam technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of high resistance factor, corroded equipment and pipelines, insufficient plugging performance, etc. The effect of bubble ability and damage avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

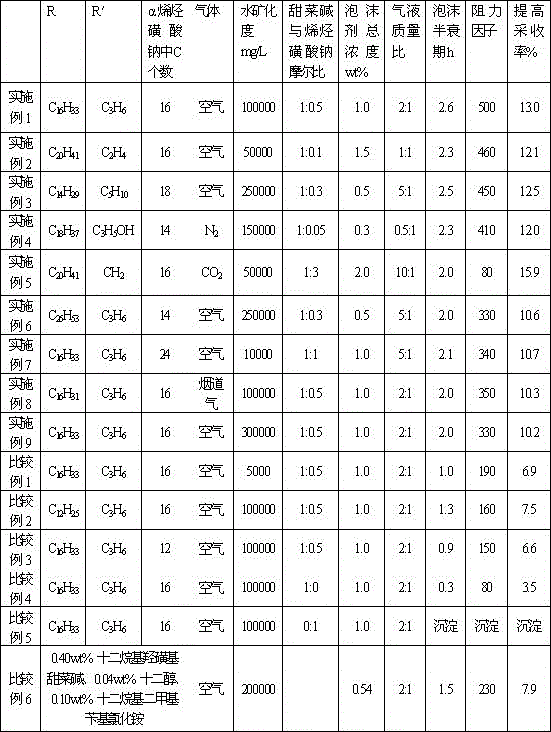

Embodiment 1

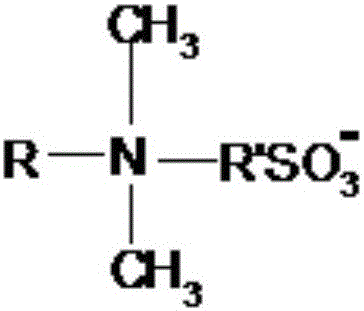

[0019] a) Add N,N-dimethylhexadecylamine and sodium 3-chloropropyl sulfonate into the reactor at a molar ratio of 1:2, and react at 80°C for 10 hours. After the reaction, wash with absolute ethanol Washing removes unreacted 3-chloropropyl sodium sulfonate, after steaming to remove solvent, obtain cetyl sulfonate betaine, content is 99.0wt%;

[0020] b) Dissolve cetyl sulfonate betaine and sodium cetyl alpha olefin sulfonate prepared in a) in water with a salinity of 100,000 mg / L at a molar ratio of 1:0.5, and the total mass fraction of the foaming agent is 1.0% , mixed uniformly to form a foam agent aqueous solution, and then mixed with the foam flooding gas at a mass ratio of 2:1 to form the required enhanced foam flooding composition.

[0021] Take the above-mentioned foaming agent aqueous solution, and use a foam scanner to conduct a foam stability experiment at 60°C, with an airflow rate of 100mL / min, using a No. 2 sand core, and stop foaming for 30 seconds. Record the tim...

Embodiment 2

[0025] a) Add N,N-dimethyleicosylamine and sodium 2-chloroethylsulfonate into the reaction kettle at a molar ratio of 1:1, and react at 70°C for 10 hours. After the reaction, wash with absolute ethanol Washing removes unreacted sodium 2-chloroethylsulfonate, and after steaming the solvent, obtains eicosylsulfonate betaine, and the content is 98.9wt %;

[0026] b) Dissolve the eicosyl sulfonate betaine and sodium hexadecane sulfonate prepared in a) in water with a salinity of 50,000 mg / L at a molar ratio of 1:0.1, and the total mass fraction of the foaming agent is 1.5% , mixed uniformly to form a foam agent aqueous solution, and then mixed with the foam flooding gas at a mass ratio of 1:1 to form the required enhanced foam flooding composition.

[0027]Take the above-mentioned foaming agent aqueous solution composition and use a foam scanner to conduct a foam stability test at 60°C. The air flow rate is 100mL / min, and the No. 2 sand core is used. The foaming stops for 30 secon...

Embodiment 3

[0031] a) Add N,N-dimethyltetradecylamine and sodium 5-chloropentylsulfonate into the reaction kettle at a molar ratio of 1:3, and react at 90°C for 3 hours. After the reaction, wash with absolute ethanol Washing removes unreacted 5-chloropentyl sodium sulfonate, and after steaming to remove the solvent, tetradecylsulfonate betaine is obtained, and the content is 99.0wt %;

[0032] b) Dissolve the tetradecyl sulfonate betaine and sodium octadecylene sulfonate prepared in a) in water with a salinity of 250,000 mg / L at a molar ratio of 1:0.3, and the total mass fraction of the foaming agent is 0.5% , mixed uniformly to form a foam agent aqueous solution, and then mixed with the foam flooding gas at a mass ratio of 5:1 to form the required enhanced foam flooding composition.

[0033] Take the above-mentioned foaming agent aqueous solution composition and use a foam scanner to conduct a foam stability test at 60°C. The air flow rate is 100mL / min, and the No. 2 sand core is used. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com