Off-resonance elliptical vibration cutting device

An elliptical vibration, cutting device technology, applied in auxiliary devices, fluids utilizing vibration, turning equipment, etc., can solve the problems of easy crosstalk, small tool displacement, lack of flexibility, etc., to achieve simple and reliable preloading methods and ensure processing efficiency. , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

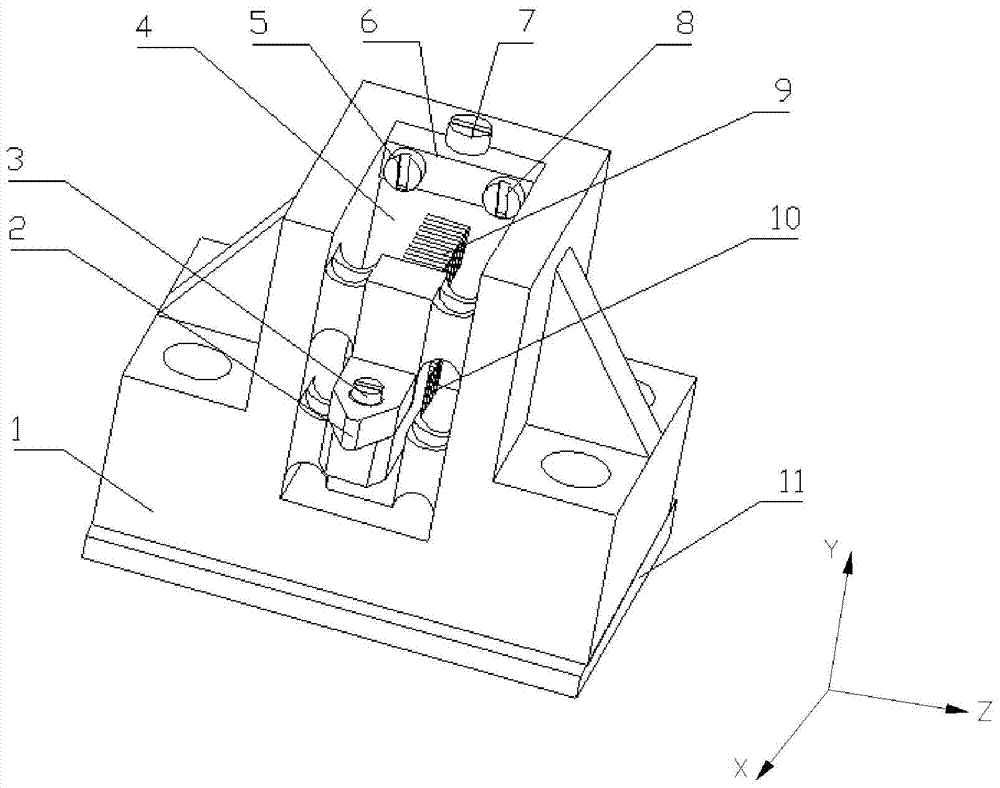

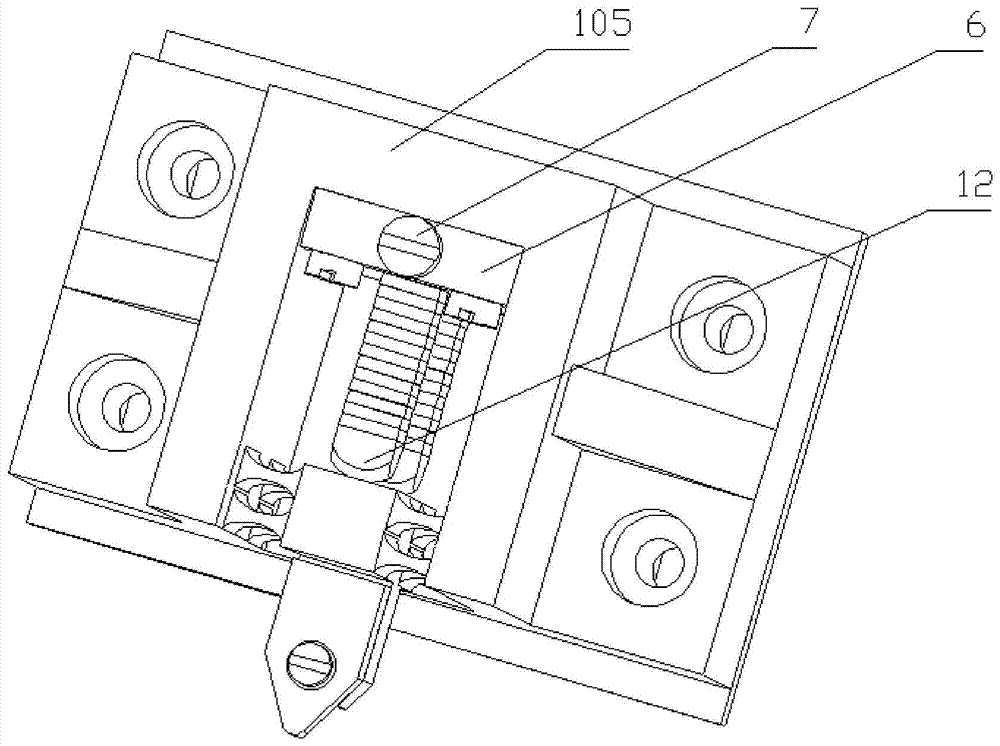

[0027] The diamond tool 2 is fixedly connected with the tool holder at the front of the base body 1 through the fastening screw 3, the end of the X-direction piezoelectric stack 9 and the end of the piezoelectric stack 10 are in contact with the lower wedge block 402, and the upper wedge block 401 is in contact with the lower wedge. The block 402 contacts to constitute the wedge block pre-tightening mechanism 4, the wedge block baffle plate 6 is fixedly connected to the base back plate 105 by the fastening screw one 5 and the fastening screw two 8; the wedge block pre-tightening screw 7 is threadedly connected to the wedge block baffle plate 6 , And connect with the upper wedge block 401;

[0028] The piezoelectric stack 9 and the piezoelectric stack 10 are arranged parallel to each other, and the free end of each piezoelectric stack is respectively fixed with a stainless steel spherical crown 12, and is respectively connected to the rear plane of the tool holder in the form of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com